Treatment method of waste gas produced by dicumyl peroxide

A dicumyl peroxide and treatment method technology, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve the problems of high cost of wastewater treatment, large energy consumption, complex process, etc., to reduce emissions, The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

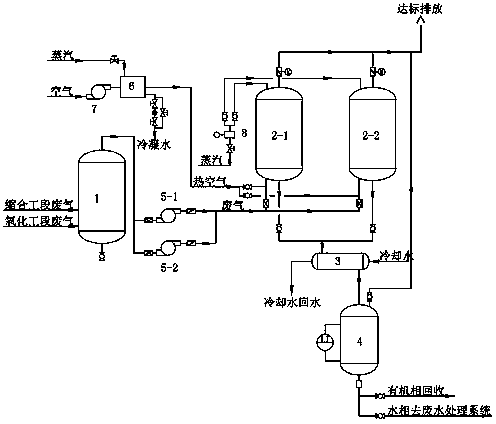

[0027] Such as figure 1 As shown, the present invention provides a kind of processing method of waste gas produced by dicumyl peroxide, and used waste gas treatment device comprises collection tank 1, activated carbon adsorption tank, condenser 3, separatory tank 4, exhaust fan 5, air heat exchange Device 6, air blower 7 and steam flowmeter 8, are connected by pipeline between each device, and described processing method comprises following process:

[0028] (a) Collection of waste gas: through the collection tank 1, collect the exhaust gas from the oxidation section and the condensation section after freezing treatment, the exhaust gas from the oxidation section and the exhaust gas from the condensation section. 3 / h, the organic matter mainly includes methanol, cumene, and non-methane total hydrocarbons, and the exhaust gas volume of the condensation section is 1000-2000Nm 3 / h, the organic substances mainly include methanol, cumene, non-methane total hydrocarbons, and ace...

Embodiment 2

[0033] Such as figure 1 As shown, the present invention provides a kind of processing method of waste gas produced by dicumyl peroxide, and used waste gas treatment device comprises collection tank 1, activated carbon adsorption tank, condenser 3, separatory tank 4, exhaust fan 5, air heat exchange Device 6, air blower 7 and steam flowmeter 8, are connected by pipeline between each device, and described processing method comprises following process:

[0034] (a) Collection of waste gas: through the collection tank 1, collect the exhaust gas from the oxidation section and the condensation section after freezing treatment, the exhaust gas from the oxidation section and the exhaust gas from the condensation section. 3 / h, the organic matter mainly includes methanol, cumene, and non-methane total hydrocarbons, and the exhaust gas volume of the condensation section is 1000-2000Nm 3 / h, the organic substances mainly include methanol, cumene, non-methane total hydrocarbons, and aceto...

Embodiment 3

[0039] Such as figure 1 As shown, the present invention provides a kind of processing method of waste gas produced by dicumyl peroxide, and used waste gas treatment device comprises collection tank 1, activated carbon adsorption tank, condenser 3, separatory tank 4, exhaust fan 5, air heat exchange Device 6, air blower 7 and steam flowmeter 8, are connected by pipeline between each device, and described processing method comprises following process:

[0040] (a) Collection of waste gas: through the collection tank 1, collect the exhaust gas from the oxidation section and the condensation section after freezing treatment, the exhaust gas from the oxidation section and the exhaust gas from the condensation section. 3 / h, the organic matter mainly includes methanol, cumene, and non-methane total hydrocarbons, and the exhaust gas volume of the condensation section is 1000-2000Nm 3 / h, the organic substances mainly include methanol, cumene, non-methane total hydrocarbons, and ace...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap