Method for preparing coal-based composite chelating agent from triethylene tetramine as raw material

A triethylene and chelating agent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve complex and high manufacturing cost problems, achieve wide application range, simple preparation, good adsorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Now take 10g Shenfu coal powder as the coal powder source, and the method for preparing the coal-based composite chelating agent with triethylenetetramine as the main raw material consists of the following steps:

[0019] (1) Weigh 10 g of raw coal powder with a particle size of 0.075 to 0.113 mm, add it to 100 mL of distilled water, mix well, weigh 0.3 g γ-aminopropyltriethoxysilane and add it to the coal powder solution to make the raw coal powder The mass ratio of γ-aminopropyltriethoxysilane to γ-aminopropyltriethoxysilane is 1:0.03, and the coupling reaction is stirred at 70°C for 3 hours to obtain coupled modified coal powder;

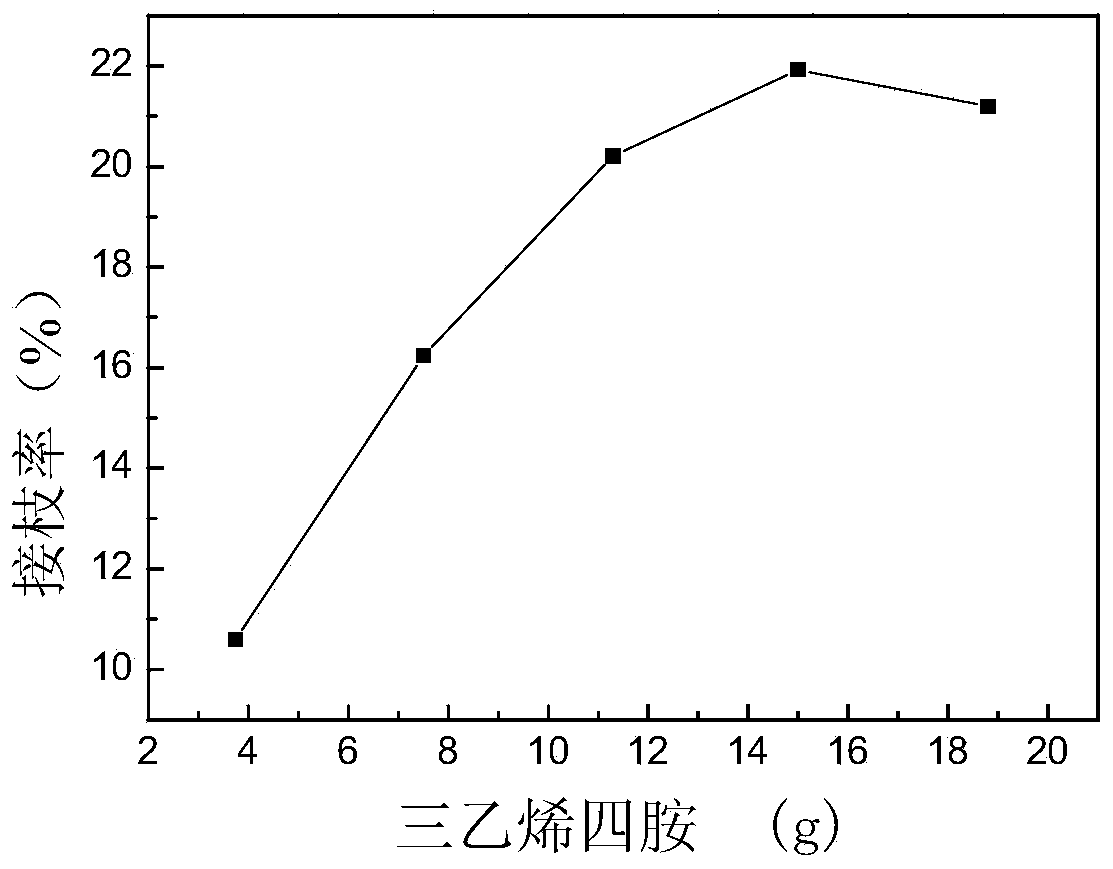

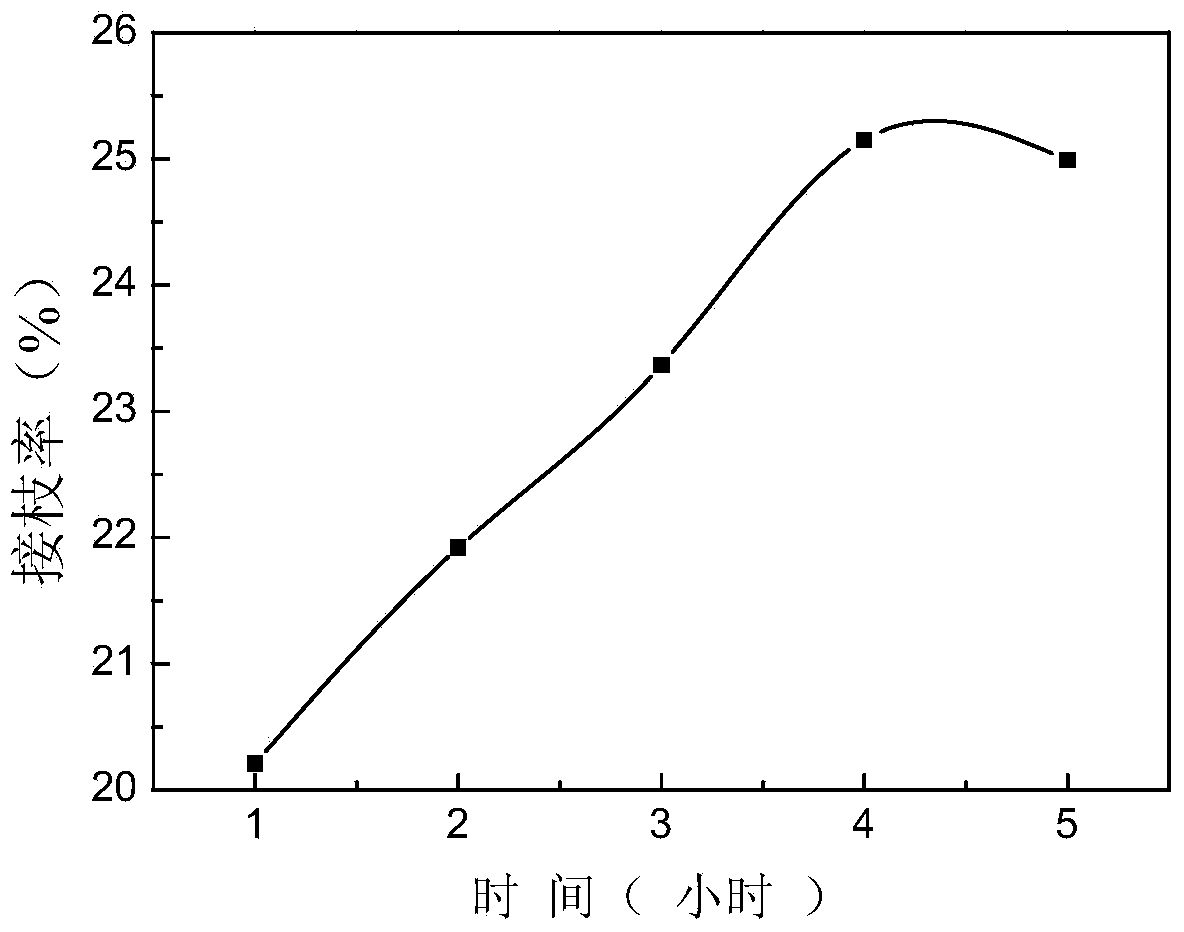

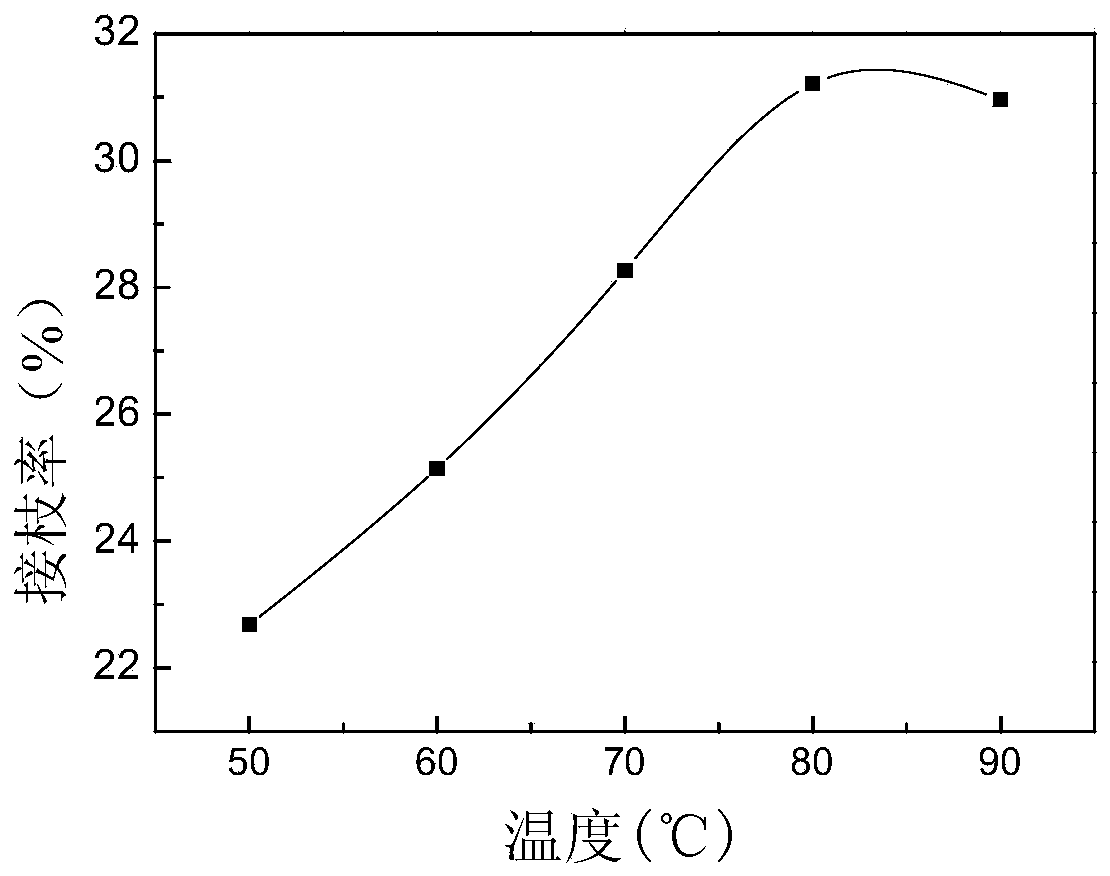

[0020] (2) Measure 7.5g of triethylenetetramine, add it to the coupling modified coal powder in step (1), make the mass ratio of raw coal powder and triethylenetetramine to be 1:0.75, amination reaction at 80°C for 4 hours , to obtain aminated coal powder;

[0021] (3) First add 6g of sodium hydroxide and then 8.8g of carbon disulfide to ...

Embodiment 2

[0023] Now take 10g Shenfu pulverized coal as the pulverized coal source, and the method for preparing the coal-based composite chelating agent taking triethylenetetramine as raw material consists of the following steps:

[0024] (1) Weigh 10 g of raw coal powder with a particle size of 0.075 to 0.113 mm, add it to 100 mL of distilled water, mix well, weigh 0.2 g γ-aminopropyltriethoxysilane and add it to the coal powder solution to make the raw coal powder The mass ratio of γ-aminopropyltriethoxysilane to γ-aminopropyltriethoxysilane is 1:0.02, and the coupling reaction is stirred at 80°C for 2 hours to obtain coupled modified coal powder;

[0025] (2) Measure 5g of triethylenetetramine, add it to the coupling modified coal powder in step (1), make the mass ratio of raw coal powder and triethylenetetramine be 1:0.5, amination reaction at 75°C for 3 hours, Obtain aminated coal powder;

[0026] (3) First add 5g of sodium hydroxide and then 3.75g of carbon disulfide to the amin...

Embodiment 3

[0028] Now take 10g Shenfu pulverized coal as the pulverized coal source, and the method for preparing the coal-based composite chelating agent taking triethylenetetramine as raw material consists of the following steps:

[0029] (1) Weigh 10g of raw coal powder with a particle size of 0.075-0.113mm, add it to 100mL of distilled water, mix well, weigh 0.5g of γ-aminopropyltriethoxysilane and add it to the coal powder solution to make the raw coal powder The mass ratio of γ-aminopropyltriethoxysilane to γ-aminopropyltriethoxysilane is 1:0.05, and the coupling reaction is stirred at 60°C for 4 hours to obtain coupled modified coal powder;

[0030] (2) Measure 15g of triethylenetetramine, add it to the coupling modified coal powder in step (1), make the mass ratio of raw coal powder and triethylenetetramine to be 1:1.5, amination reaction at 70°C for 4 hours, Obtain aminated coal powder;

[0031] (3) First add 15g of sodium hydroxide and then 15g of carbon disulfide to the amina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com