Method for preparing gold kernel cuprous oxide shell composite nanometer structure, and composite nanometer structure

A composite nanostructure, cuprous oxide shell technology, applied in the field of nanoparticles, can solve the problem that the optical properties of gold nanoparticles and cuprous oxide cannot be changed, the interaction between gold core and cuprous oxide shell cannot be reflected, Large particle size and other problems, to achieve the effect of cheap and non-toxic reagents, high yield, and good size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

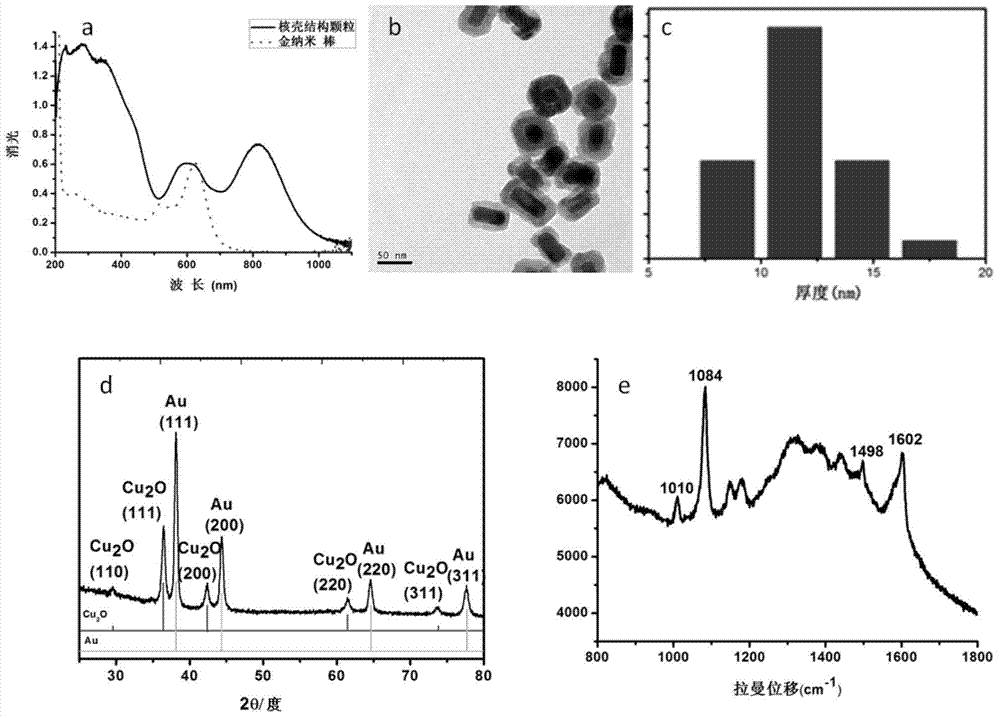

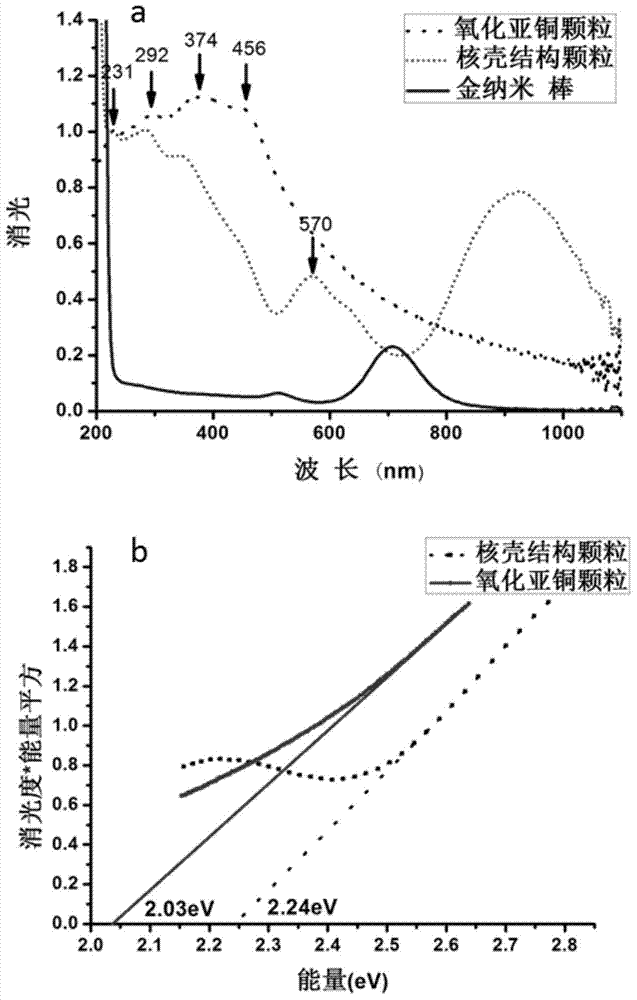

[0042] To the cetyltrimethylammonium bromide aqueous solution with a concentration of 0.033M, 1mM copper chloride aqueous solution, 0.33nM gold nanorods, 7.5mM sodium hydroxide aqueous solution and 3mM ascorbic acid aqueous solution were respectively added to the final concentration. The mixed solution was placed in a 30°C water bath for 22 minutes to obtain a gold core cuprous oxide shell structure. After adding ascorbic acid, the solution changed from reddish brown to purple red and finally grayish green in about 10 seconds. After 25 minutes, the solution was taken out and centrifuged at 8000 rpm for 3 minutes to obtain gold nanorod core cuprous oxide shell particles.

[0043] Then add 4-ATP solution, let stand for 3 hours, centrifuge several times, and then perform Raman experiment. Pure cuprous oxide particles were obtained without adding gold nanorods according to the above method, and the band gaps of the composite nanostructure particles and cuprous oxide particles were...

Embodiment 2-5

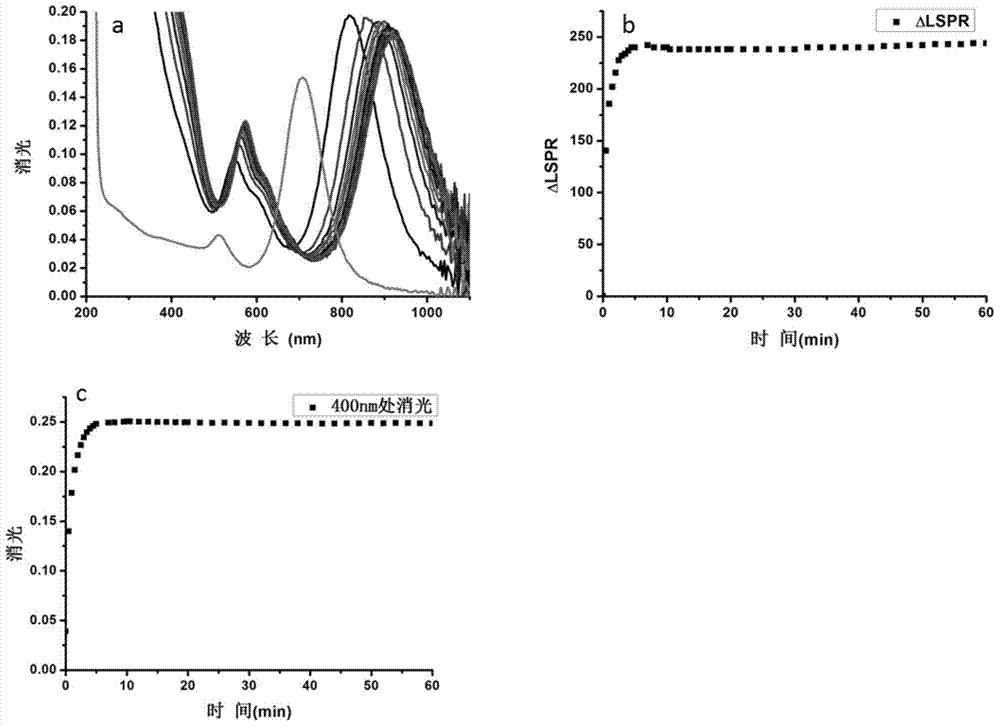

[0045] Embodiment 2-5: the influence of sodium hydroxide concentration

[0046] Gold core cuprous oxide shell structures were prepared according to the method of Example 1, except that aqueous sodium hydroxide solutions with final concentrations of 5mM, 7.5mM, 10mM, 15mM, 20mM and 25mM were added respectively. Determination of the relationship between the characteristic parameters of the ultraviolet-visible-near-infrared extinction spectrum of the gold nanorod solution and the peak value of the long-wave surface plasmon resonance absorption peak and the concentration of sodium hydroxide, the measurement results are as follows Figure 4 (a) and Figure 4 Shown in (b); SEM images of observed structures, such as Figure 5 shown.

[0047] When the amount of sodium hydroxide added is less than 15mM, sodium hydroxide cannot put all Cu 2+ Converted into copper hydroxide, so the final cuprous oxide shell layer is very thin, and the amount of red shift of the corresponding long-wave...

Embodiment 6-9

[0048] Examples 6-9: Effect of Surfactant Concentration

[0049] The gold core cuprous oxide shell structure was prepared according to the method of Example 1, except that the surfactant hexadecyltrimethylammonium bromide with a final concentration of 0.01M, 0.033M, 0.06M and 0.09M was added respectively . Determination of the ultraviolet-visible-near-infrared extinction spectrum characteristic parameter determination result of gold core cuprous oxide shell structure solution is as follows Figure 6 As shown in (a), the relationship between the peak value of the long-wave surface plasmon resonance absorption peak and the concentration of cetyltrimethylammonium bromide is as follows Figure 6As shown in (b); the scanning electron microscope image for observing the structure of the gold core cuprous oxide shell is as follows Figure 7 .

[0050] As can be seen from Examples 6-9, if the concentration of cetyltrimethylammonium bromide is lower than 30mM, the obtained cuprous ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bandgap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com