Separation method for phenol compounds and nitrogen-containing compounds in coal tar

A technology of phenolic compounds and nitrogen compounds, applied in tar processing through heat treatment, tar processing through chemical extraction, tar processing through selective solvent extraction, etc., can solve the problem of consuming large acid-base solution, increasing hydrogen consumption, and polluting the environment Pollution and other issues, to achieve the effect of low equipment investment and operating costs, reduced production costs, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

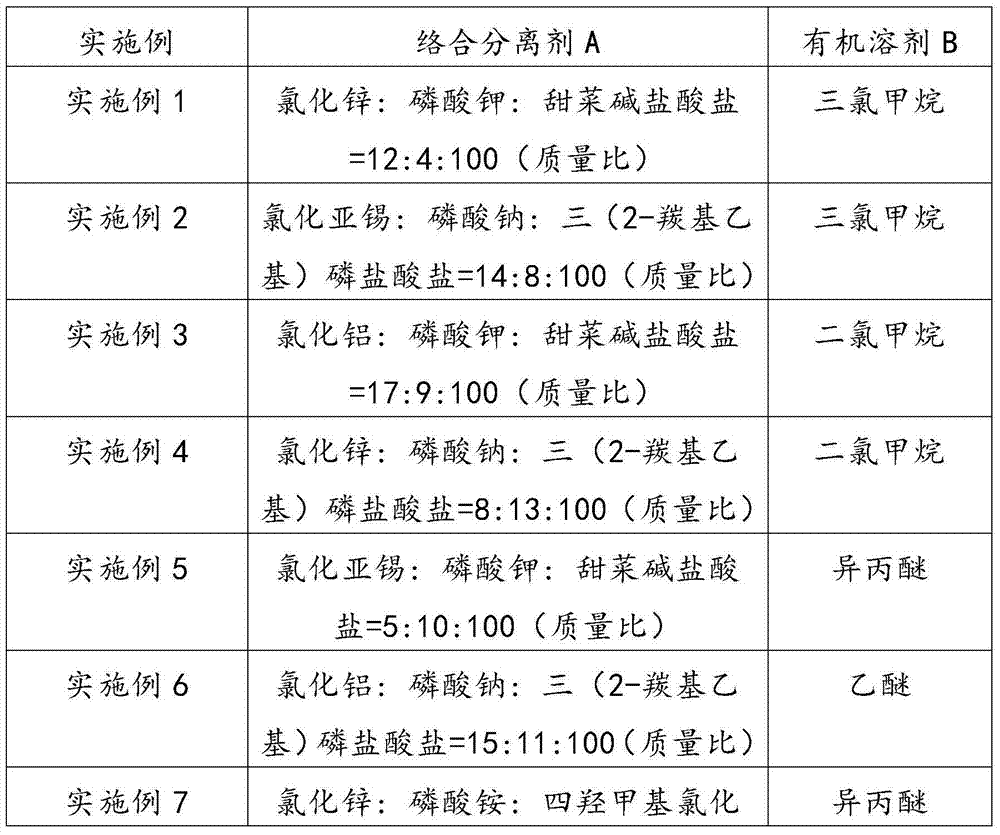

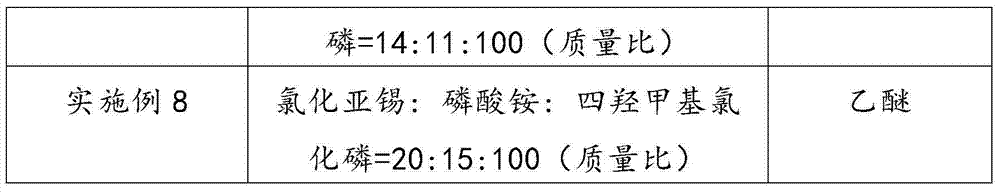

Examples

Embodiment 1

[0028] The process conditions described in this example are: at 10°C, complexing and separating agent A is added to coal tar (coal tar comes from Wuhan Iron and Steel Coking Plant, distillation range: 170-230°C), the mass ratio of the two is 1:10, After stirring for 50 minutes, it was allowed to stand still for 8 minutes, and the phenolic content and nitrogen content of the separated coal tar were measured. The separation efficiency of phenolic compounds was 81.2%, and the separation efficiency of nitrogenous compounds was 71.1%. The obtained complex was heated at 200° C. for 1 h to selectively separate nitrogen-containing compounds. According to elemental analysis, the separation efficiency of nitrogen-containing compounds was 82.7%.

[0029] Add 300g of organic solvent B to the complex after the nitrogen-containing compound is separated, stir at 40°C for 20 minutes, then let it stand for 10 minutes, and recover the complexing and separating agent A through a bag filter. Afte...

Embodiment 2

[0032] The process conditions described in this example are: at 60°C, add complexing and separating agent A to coal tar (coal tar comes from Wuhan Iron and Steel Coking Plant, distillation range: 170-230°C), the mass ratio of the two is 1:10, After stirring for 20 minutes, it was allowed to stand still for 8 minutes, and the phenol content and nitrogen content of the separated coal tar were measured. The separation efficiency of phenolic compounds was 79.7%, and the separation efficiency of nitrogen compounds was 70.4%. The obtained complex was heated at 140° C. for 0.2 h to selectively separate nitrogen-containing compounds. According to elemental analysis, the separation efficiency of nitrogen-containing compounds was 81.4%.

[0033] Add 300g of organic solvent B to the complex after the nitrogen-containing compound is separated, stir at 60°C for 1 min, then let it stand for 10 min, and recover the complexing and separating agent A through a bag filter. After the above proce...

Embodiment 3

[0035] The process conditions described in this example are: at 40°C, complexing and separating agent A is added to coal tar (coal tar comes from Wuhan Iron and Steel Coking Plant, distillation range: 170-230°C), the mass ratio of the two is 0.8:10, After stirring for 8 minutes, it was left standing for 8 minutes to measure the phenolic content and nitrogen content of the separated coal tar. The separation efficiency of phenolic compounds was 68.6%, and the separation efficiency of nitrogenous compounds was 64.4%. The obtained complex was heated at 110° C. for 1 h to selectively separate nitrogen-containing compounds. According to elemental analysis, the separation efficiency of nitrogen-containing compounds was 57.4%.

[0036] Add 300g of organic solvent B to the complex after the nitrogen-containing compound is separated, stir at 10°C for 30 minutes, then let it stand for 10 minutes, and recover the complexing and separating agent A through a bag filter. After the above proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com