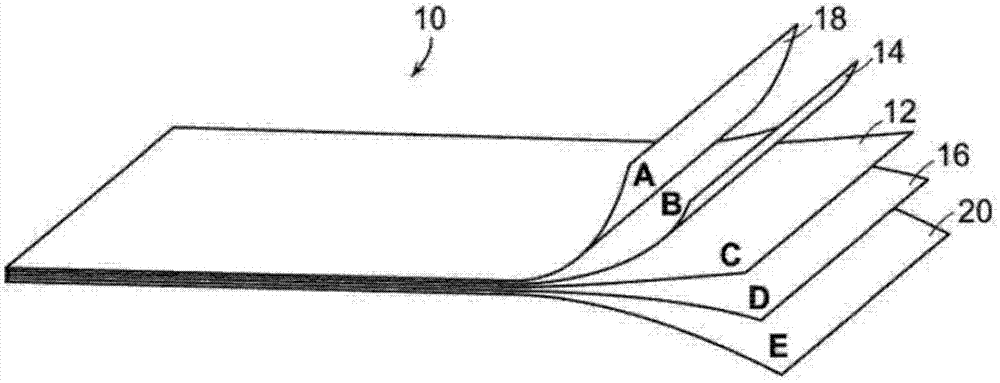

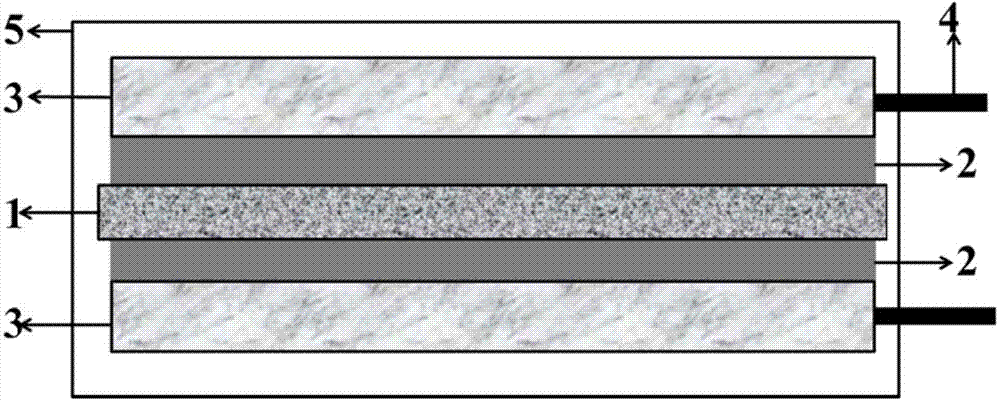

Flexible supercapacitor and manufacturing method thereof

A supercapacitor and flexible technology, applied in the field of capacitors, can solve the problems of damage to the film, complicated operation methods, damage, etc., and achieve the effects of low preparation cost, simple packaging method, and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of a flexible supercapacitor obtained by using polyaniline as electrode material, organic filter membrane as ion permeable membrane, copper foil as electrical contact, PET as packaging material, and KOH as electrolyte:

[0023] Step 1: Cut the organic filter membrane into a size of 6cm×8cm, and clean the surface with degreaser, deionized water and absolute ethanol in sequence;

[0024] Step 2: In a 500mL beaker, add 340mL of deionized water, 8mL of concentrated sulfuric acid and 3mL of aniline monomer, stir for 30min to make it evenly mixed;

[0025] Step 3: Put the organic filter membrane cleaned in step 1 into the mixed solution obtained in step 2 above, and stir at a constant speed for 2 hours;

[0026] Step 4: Dissolve 2 g of ammonium persulfate in 60 mL of deionized water, add the ammonium persulfate solution dropwise into the mixed solution soaked in the organic filter membrane in step 3 using a dropping funnel, and stir at a constant speed ...

Embodiment 2

[0033] The preparation method of a flexible supercapacitor obtained by using nickel hydroxide as electrode material, organic filter membrane as ion permeable membrane, copper foil as electrical contact, PET as packaging material, and KOH as electrolyte:

[0034] Step 1: Cut the organic filter membrane into a size of 6cm×8cm, and clean the surface with degreaser, deionized water and absolute ethanol in sequence;

[0035] Step 2: Add 10.5 g of nickel sulfate to 40 mL of deionized water to obtain a uniform nickel sulfate solution; add 2.03 g of potassium persulfate to 30 mL of deionized water to obtain a solution of potassium persulfate;

[0036] Step 3: Mix nickel sulfate solution and potassium persulfate solution evenly, add 20mL of 25% (mass fraction) ammonia water to form a mixed solution, put the organic filter membrane cleaned in step 1 into the mixed solution and stir at a constant speed for 30 minutes;

[0037] Step 4: After the reaction is over, take out the organic filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com