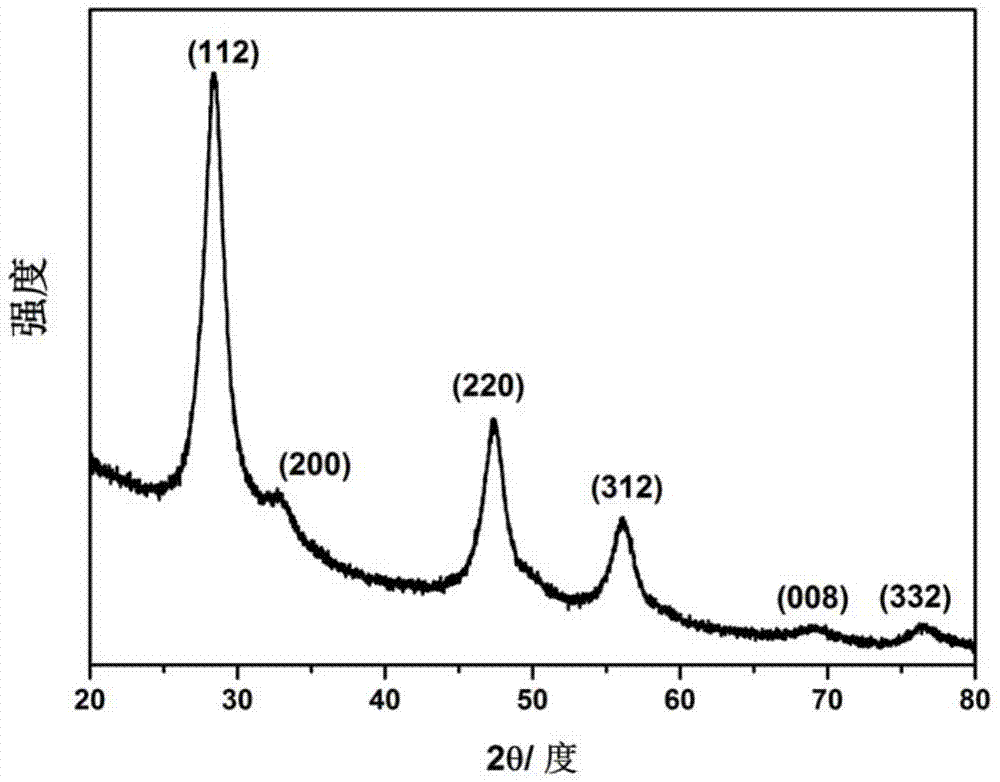

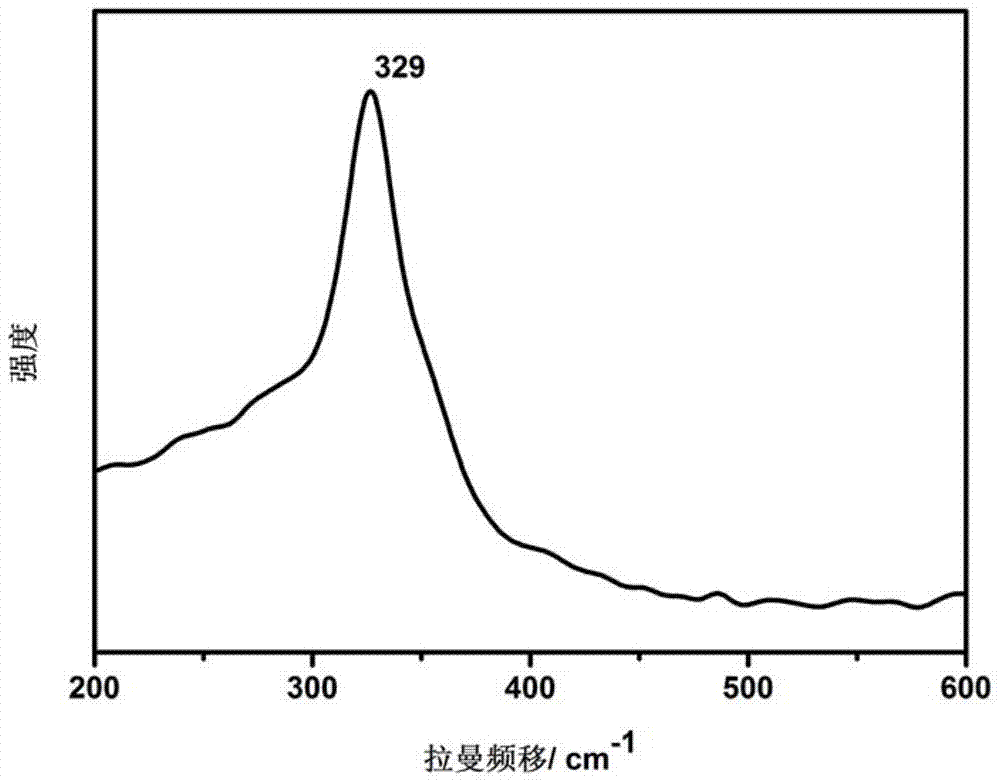

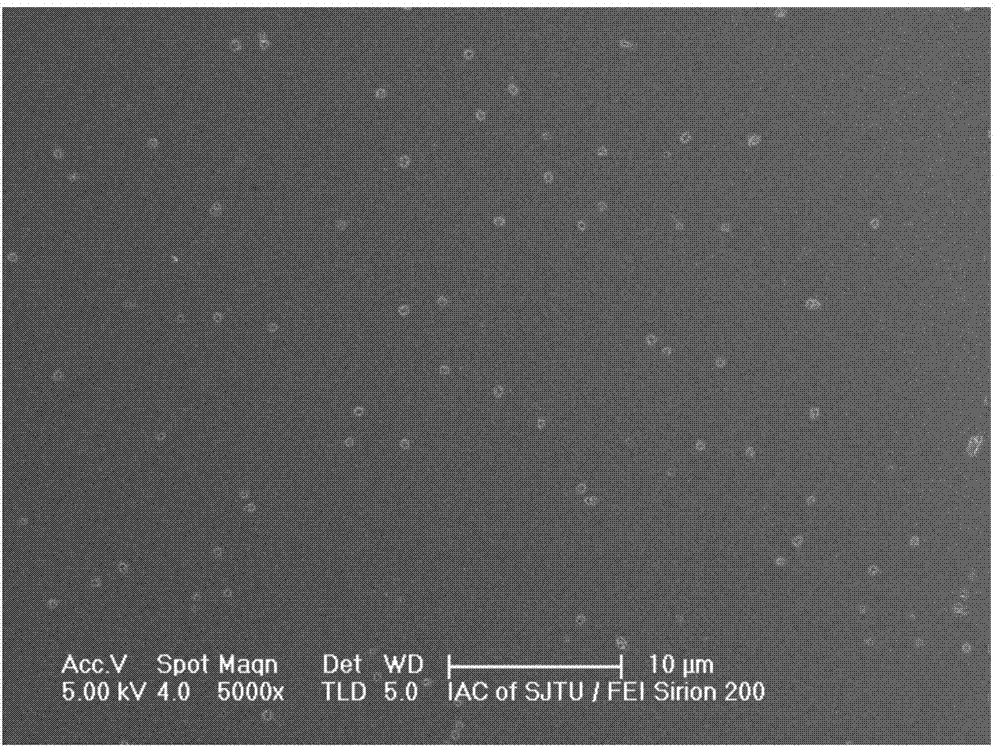

Copper-zinc-tin-sulfur (CZTS) thin film and preparation method and purposes thereof

A copper-zinc-tin-sulfur and thin-film technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., to achieve good compactness, simple and easy preparation method, and good photoelectrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of CuZnSnS thin film

[0042] (1) Dissolve cupric chloride, zinc chloride, stannous chloride and thiourea in methanol or ethanol at a molar ratio of 0.5:1:0.5:5 at room temperature, and stir until clear and transparent to obtain a precursor solution;

[0043] (2) The substrate FTO was ultrasonically cleaned successively in acetone, ethanol, and deionized water, and the cleaning time was 5 minutes;

[0044] (3) The precursor solution is spin-coated on the substrate FTO, the spin-coating rate is 2000 rpm, and the spin-coating time is 30 seconds; and then dried at 150° C. for 10 minutes. This step is repeated several times until the desired film thickness is obtained.

[0045] (4) The sample obtained in step (3) is placed in argon or nitrogen, and calcined at 350° C. for 1 hour to obtain a copper-zinc-tin-sulfur thin film.

[0046] 2. Preparation of copper zinc tin sulfur / cadmium sulfide / titanium dioxide thin film

Embodiment 2

[0063] 1. Preparation of copper-zinc-tin-sulfur thin films

[0064] (1) at room temperature, copper chloride, zinc chloride, stannous chloride and thiourea are jointly dissolved in methanol or ethanol in a molar ratio of 0.5:1:0.5:4, and stirred until clear and transparent to obtain a precursor solution;

[0065] (2) The substrate FTO was ultrasonically cleaned in acetone, ethanol and deionized water respectively, and the cleaning time was 5 minutes;

[0066] (3) Spin-coating the precursor solution on the substrate FTO, the spin-coating speed is 300 rpm, and the spin-coating time is 120 seconds; and then dried at 100° C. for 30 minutes. This step is repeated several times until the desired film thickness is obtained.

[0067] (4) The sample obtained in step (3) is placed in argon or nitrogen, and calcined at 200° C. for 1 hour to obtain a copper-zinc-tin-sulfur thin film.

[0068] 2. Preparation of copper-zinc-tin-sulfur / cadmium sulfide / titanium dioxide thin films

[0069] ...

Embodiment 3

[0073] 1. Preparation of copper-zinc-tin-sulfur thin films

[0074] (1) at room temperature, copper chloride, zinc chloride, stannous chloride and thiourea are jointly dissolved in methanol or ethanol in a molar ratio of 2:1:1:20, and stirred until clear and transparent to prepare a precursor solution;

[0075] (2) The substrate FTO was ultrasonically cleaned successively in acetone, ethanol and deionized water, and the cleaning time was 30 minutes;

[0076] (3) Spin-coating the precursor solution on the substrate FTO, the spin-coating speed is 3500 rpm, and the spin-coating time is 5 seconds; and then dried at 200° C. for 5 minutes. This step is repeated several times until the desired film thickness is obtained.

[0077] (4) The sample obtained in step (3) is placed in argon or nitrogen, and calcined at 600° C. for 1 hour to obtain a copper-zinc-tin-sulfur thin film.

[0078] 2. Preparation of copper-zinc-tin-sulfur / cadmium sulfide / titanium dioxide thin films

[0079] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com