Preparation method of zwitter-ion/grapheme composite hydrogel

A graphene composite, zwitterion technology, applied in the field of graphene hydrogel preparation, achieves the effects of high mechanical strength, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

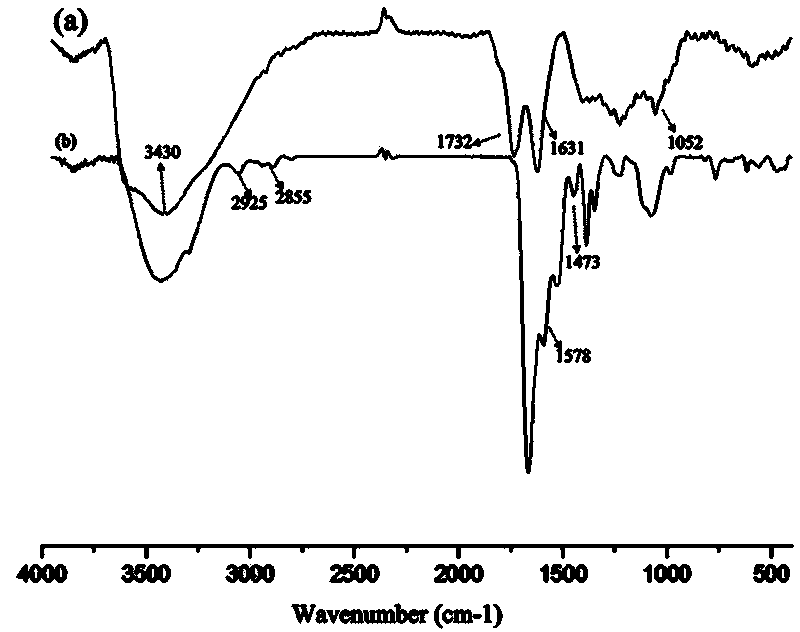

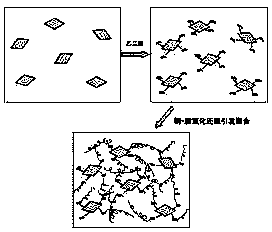

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 30g of dense crystalline graphite, 15g of sodium nitrate, and 690mL of concentrated sulfuric acid, mix them evenly and place them in an ice bath (0°C) and stir for 4 hours, then slowly add 90g of potassium permanganate to the reactant, Continue stirring at 35°C for 30 minutes; slowly add 1380mL of water to the reactant, transfer the reactant to a 98°C water bath and stir for 15 minutes, then cool down to room temperature; add 4200mL of pure water and 30mL (30%) to the reaction system Hydrogen peroxide, after stirring and cooling, filtering, centrifuging and washing three times, finally drying the bright yellow precipitate to obtain graphite oxide; configuring graphite oxide into 1000 ml of graphene oxide solution with a concentration of 12 mg / ml, adding 80 g of ethylenediamine, Ultrasonic dispersion for 10 minutes, reflux at 80°C for 32 hours, remove the supernatant, wash with water until neutral, and dry at 60°C to obtain aminated graphene oxide; put aminated g...

Embodiment 2

[0035] (1) Using pre-oxidized graphite as a raw material, the same process steps as in Example 1 were used to prepare an aminated graphene dispersion with a mass concentration of 20.0 mg / mL;

[0036] (2) Add 19.995g of aminated graphene dispersion, 40g of pure water, and 40g of 1-carboxy-N,N-dimethyl-N-acrylamidopropyl inner salt monomer into the reactor, and stir evenly; Add 0.005g CuSO 4 , stirred evenly, and polymerized at 90°C for 5 min to obtain a zwitterion / graphene composite hydrogel.

[0037] The mechanical properties of the hydrogel were tested by a universal material testing machine, and the results showed that the tensile strength at break reached 0.9 MPa, and the elongation at break reached 3300%.

[0038]

Embodiment 3

[0040] (1) Using graphite flakes as a raw material, the same process steps as in Example 1 were used to prepare an aminated graphene dispersion with a mass concentration of 20.0 mg / mL;

[0041] (2) Add 30g of aminated graphene dispersion, 51.9999g of pure water, and 18g of 3-carboxy-N,N-dimethyl-N-acrylamidopropyl inner salt monomer into the reactor, and stir evenly; Add 0.0001g CuSO 4 , stirred evenly, and polymerized at 40° C. for 8 hours to obtain a zwitterion / graphene composite hydrogel.

[0042] The mechanical properties of the hydrogel were tested by a universal material testing machine, and the results showed that the tensile strength at break reached 6MPa, and the elongation at break reached 1000%.

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com