Preparation method of polyhydric aldehyde cross-linked sulfomethylated humic acid coal-water slurry dispersant

A technology of sulfomethylation and humic acid, applied in the field of coal-water slurry dispersant, can solve the problems of unsatisfactory stability of coal-water slurry, low molecular mass, complicated process of humic acid dispersant, etc. Electrostatic repulsion, effect of reducing apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

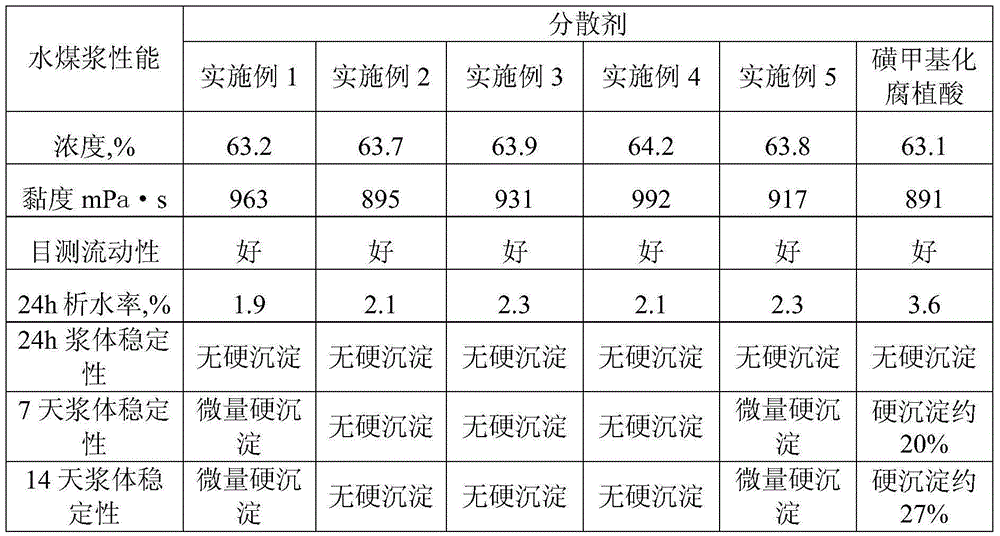

Examples

Embodiment 1

[0016] In parts by mass, dissolve 50 parts of sodium humate in 150 parts of water to obtain mixture A, adjust the pH of mixture A to 10 with a mass fraction of 10% aqueous sodium hydroxide solution to obtain mixture B, and add 45 parts of mass to mixture B Formaldehyde solution with a fraction of 37% was obtained as a mixture C. After the temperature of the mixture C was raised to 55°C, 37.5 parts of sodium bisulfite was added to the mixture C under stirring, and then kept for 4 hours to obtain a material A. Then, within 30 minutes, 35 parts of Add a 20% aqueous solution of glyoxal to material A and conduct heat preservation and cross-linking reaction for 3 hours to obtain material B. After the reaction, the material is discharged, and the material B is spray-dried with hot air (130°C) to obtain a brown powder.

Embodiment 2

[0018] In parts by mass, dissolve 50 parts of potassium humate in 120 parts of water to obtain mixture A, adjust the pH of mixture A to 11 with a mass fraction of 10% aqueous sodium hydroxide solution to obtain mixture B, and add 35 parts of mass to mixture B Formaldehyde solution with a fraction of 37% was obtained as mixture C. After the mixture C was heated to 55°C, 45 parts of sodium bisulfite was added to the mixture C under stirring, and then kept for 4 hours to obtain material A. Then, within 30 minutes, 25 parts by mass Add 20% aqueous solution of glutaraldehyde to material A and conduct heat preservation cross-linking reaction for 2 hours to obtain material B. After the reaction, the material is discharged, and the material B is spray-dried with hot air (140°C) to obtain a brown powder.

Embodiment 3

[0020] In terms of parts by mass, dissolve 50 parts of ammonium humate in 100 parts of water to obtain mixture A, adjust the pH of mixture A to 12 with a mass fraction of 10% aqueous sodium hydroxide solution to obtain mixture B, and add 25 parts by mass to mixture B Formaldehyde solution with a fraction of 37% was obtained as mixture C. After the temperature of mixture C was raised to 60°C, 52.5 parts of sodium bisulfite was added to mixture C under stirring, and then kept for 4 hours to obtain material A, and 25 parts by mass of Add a 20% aqueous solution of glyoxal to material A and conduct heat preservation and cross-linking reaction for 3 hours to obtain material B. After the reaction, the material is discharged, and the material B is spray-dried with hot air (180°C) to obtain a brown powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com