Multi-arc ion plated hard coating prepared by adopting frequency-modulation electromagnetic coil, and method

A multi-arc ion plating and electromagnetic coil technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc. The effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

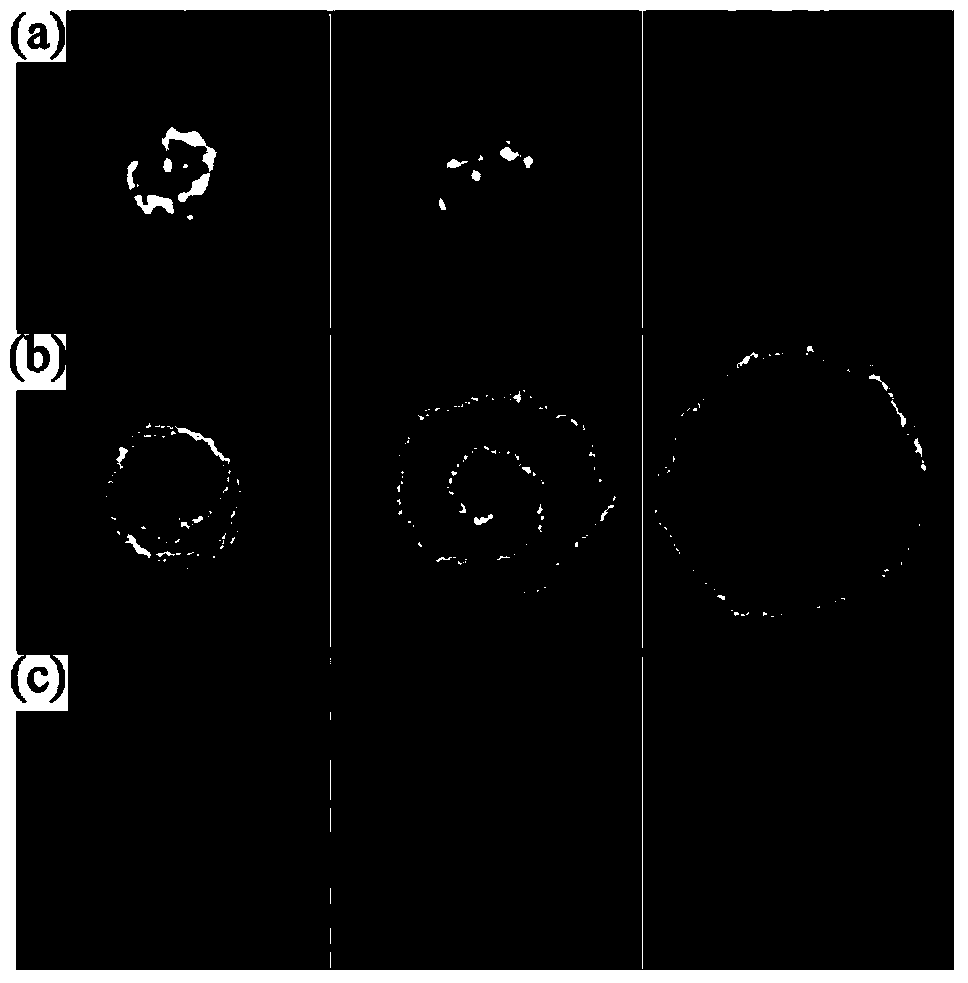

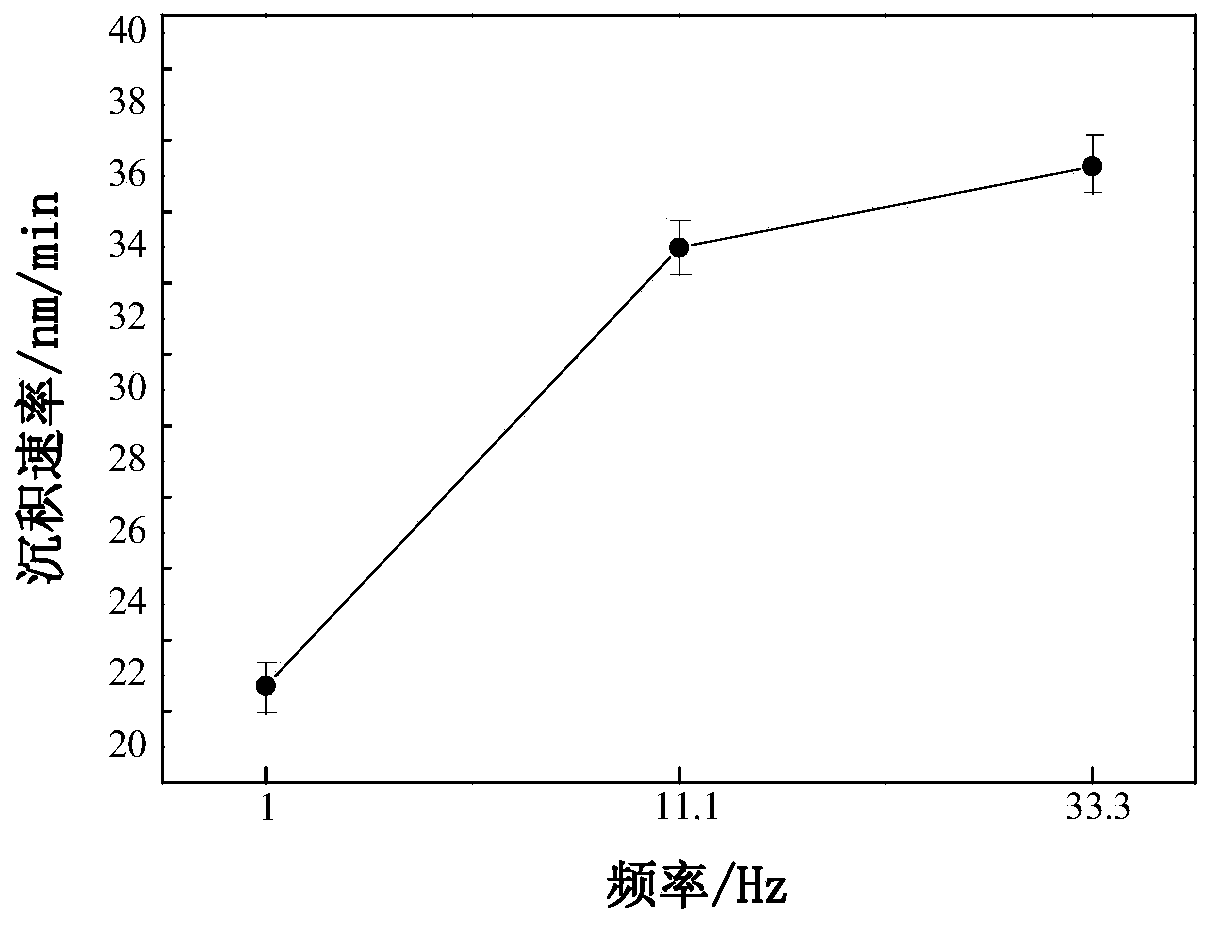

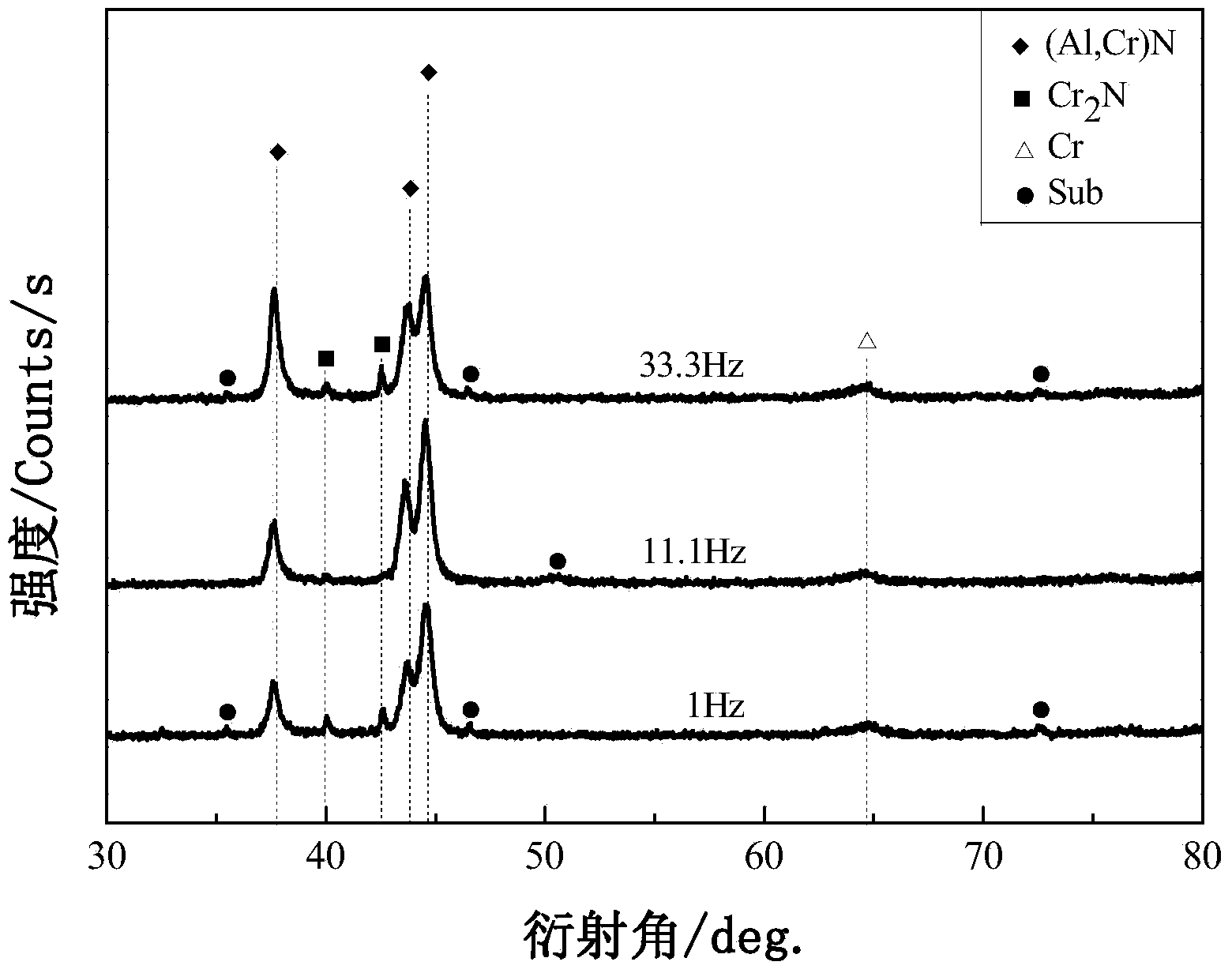

Image

Examples

Embodiment 1

[0032] The cemented carbide samples are finely ground with 800-1200# metallographic sandpaper to make the surface roughness of the substrate Ra≤0.05μm, and then the surface of the substrate after fine grinding is polished to a mirror surface, cleaned with acetone and alcohol in turn, and then blown with an air gun. After drying, put it on the substrate frame of the circular turntable, then push the circular turntable carrying the substrate frame into the deposition chamber, close the furnace door tightly, install the electromagnetic coil on the wall of the deposition chamber, and the cathode target source on the wall of the deposition chamber, the electromagnetic coil and There is only one layer of furnace wall between the cathode and target sources. Use a mechanical pump and a molecular pump to pump the background vacuum of the vacuum chamber to 3-5×10 -3 Pa, enter Ar gas, increase the pressure to 1Pa, apply a high bias voltage of -900V, and glow clean for 2 to 25 minutes; af...

Embodiment 2

[0034] The cemented carbide samples are finely ground with 800-1200# metallographic sandpaper to make the surface roughness of the substrate Ra≤0.05μm, and then the surface of the substrate after fine grinding is polished to a mirror surface, cleaned with acetone and alcohol in turn, and then blown with an air gun. After drying, put it on the substrate frame of the circular turntable, then push the circular turntable carrying the substrate frame into the deposition chamber, close the furnace door, install the electromagnetic coil on the wall of the deposition chamber, and the cathode target source on the wall of the deposition chamber. There is only one layer of furnace wall between the coil and the cathode source. Use a mechanical pump and a molecular pump to pump the background vacuum of the vacuum chamber to 3-5×10 -3 Pa, enter Ar gas, increase the pressure to 1Pa, apply a high bias voltage of -900V, and glow clean for 2 to 25 minutes; after cleaning, adjust the vacuum to 3...

Embodiment 3

[0036] The cemented carbide samples are finely ground with 800-1200# metallographic sandpaper to make the surface roughness of the substrate Ra≤0.05μm, and then the surface of the substrate after fine grinding is polished to a mirror surface, cleaned with acetone and alcohol in turn, and then blown with an air gun. After drying, put it on the substrate frame of the circular turntable, then push the circular turntable carrying the substrate frame into the deposition chamber, close the furnace door, install the electromagnetic coil on the wall of the deposition chamber, and the cathode target source on the wall of the deposition chamber. There is only one layer of furnace wall between the coil and the cathode source. Use a mechanical pump and a molecular pump to pump the background vacuum of the vacuum chamber to 3-5×10 -3 Pa, enter Ar gas, increase the pressure to 1Pa, apply a high bias voltage of -900V, and glow clean for 2 to 25 minutes; after cleaning, adjust the vacuum to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com