Copper foil for printed circuit

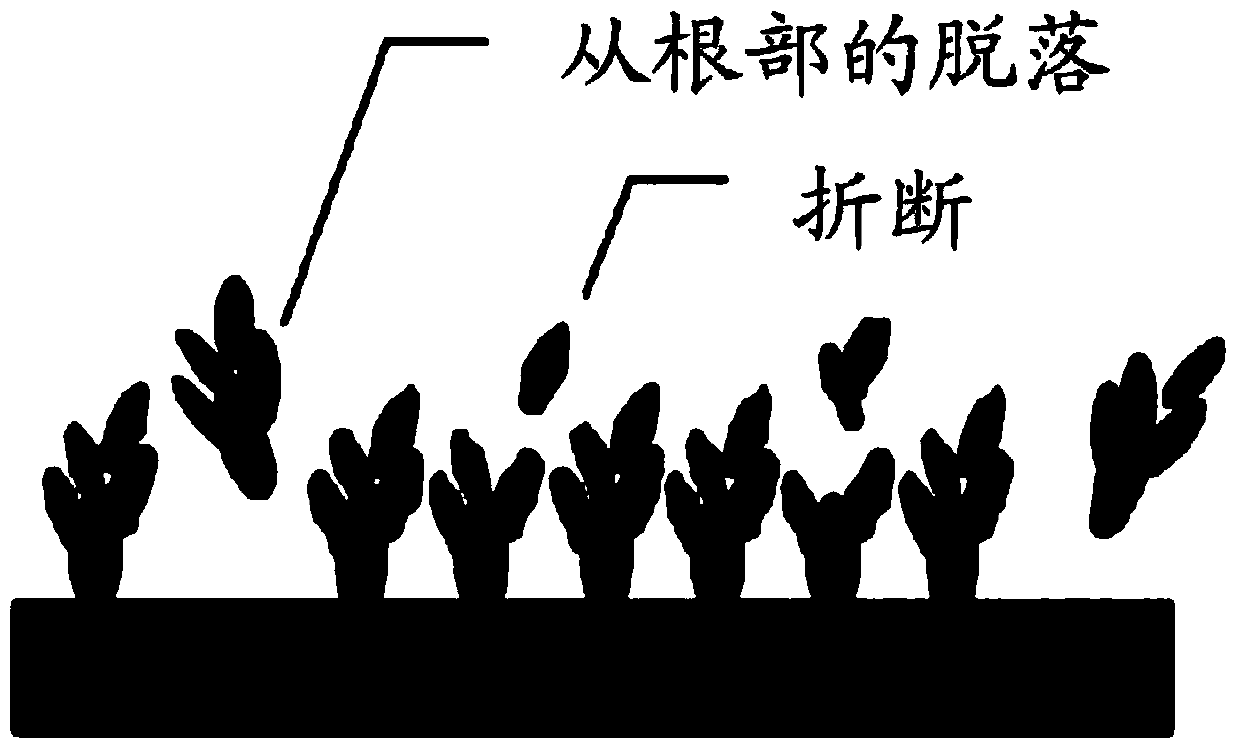

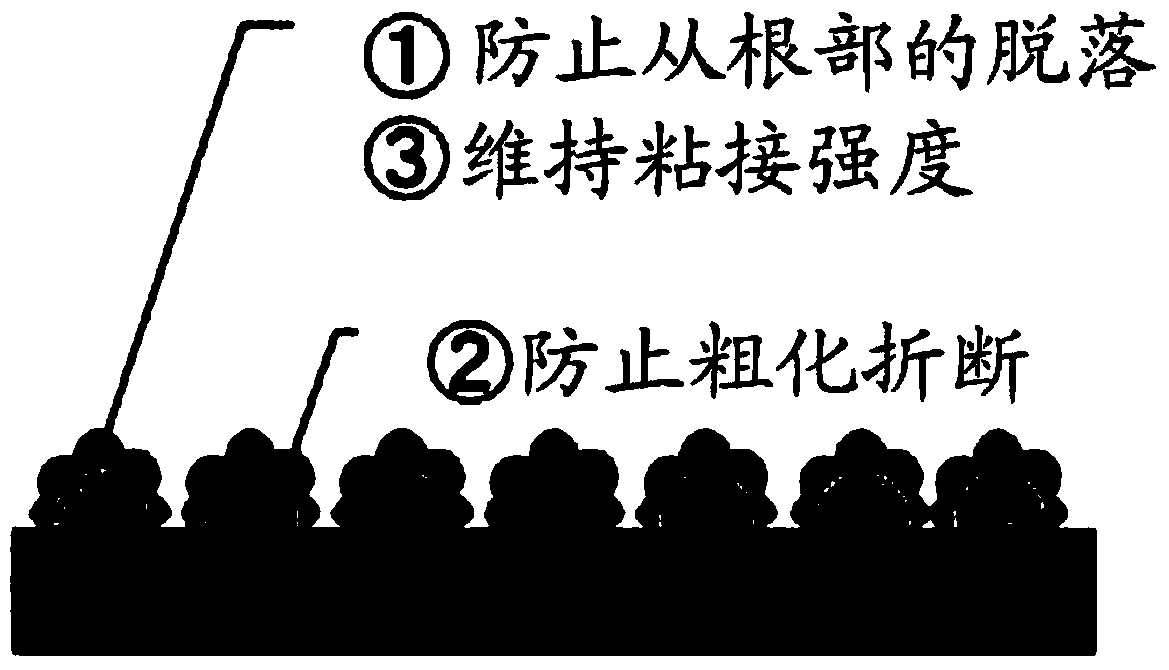

A technology of printed circuit and copper foil, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of etching residue, roller pollution, particle shedding, etc., and achieve the effect of good etching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 6

[0132] On the rolled copper foil, a primary particle layer (Cu) and a secondary particle layer (copper-cobalt-nickel alloy plating) were formed in the condition range shown below.

[0133] The plating solution composition and plating conditions used are shown below.

[0134] [Bath composition and plating conditions]

[0135] (A) Formation of primary particle layer (Cu plating)

[0136]

[0137] (B) Formation of secondary particle layer (Cu-Co-Ni alloy plating)

[0138]

[0139] The above-mentioned conditions for the formation of the primary particle layer (Cu plating) and the formation of the secondary particle layer (Cu-Co-Ni alloy plating) were adjusted so that the average height of the unevenness of the roughened surface observed with a laser microscope was 1500 or more. For the measurement of the surface area, the measurement method using the above-mentioned laser microscope was used.

Embodiment 1

[0154] Embodiment 1 is to form the current density of the primary particle as 65A / dm 2 and 20A / dm 2 , Set the Coulomb amount to 80As / dm 2 and 30As / dm 2 In the case of , the current density for forming secondary particles is set to 28A / dm 2 , set the Coulomb amount to 20As / dm 2 Case.

[0155] Furthermore, the current density and the coulomb quantity for forming primary particles are two stages, and in the case of forming primary particles, two stages of electroplating are generally required. That is, the plating conditions for the formation of nuclei particles in the first stage and the electroplating for the growth of nuclei particles in the second stage.

[0156] The initial plating conditions are plating conditions for the formation of nucleation particles in the first stage, and the subsequent plating conditions are plating conditions for the growth of nuclei particles in the second stage. The same applies to the following examples and comparative examples, and thus d...

Embodiment 2

[0159] Embodiment 2 is to form the current density of the primary particle as 65A / dm 2 and 2A / dm 2 , Set the Coulomb amount to 80As / dm 2 and 4As / dm 2 In the case of , the current density for forming secondary particles is set to 25A / dm 2 , set the Coulomb amount to 15As / dm 2 Case.

[0160] As a result, the average particle diameter of the primary particles was 0.40 μm, the average particle diameter of the secondary particles was 0.15 μm, and the average height of the irregularities on the roughened surface observed with a laser microscope was 1556, which satisfied the conditions of the present invention. .

[0161] As a result, it has the following characteristics, that is, less powder shedding, high normal peel strength of 0.89kg / cm, heat resistance deterioration rate (measure the peel strength after heating at 180°C for 48 hours after the normal peel measurement, and set the difference as is the degradation rate) as small as 30% or less.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Normal peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com