Preparation method for composite material of hydrophilic fullerene derivative and metallic oxide

A technology of fullerene derivatives and composite materials, which is applied in the field of preparation of hydrophilic fullerene derivatives and metal oxide composite materials, can solve the problem of free radical removal and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

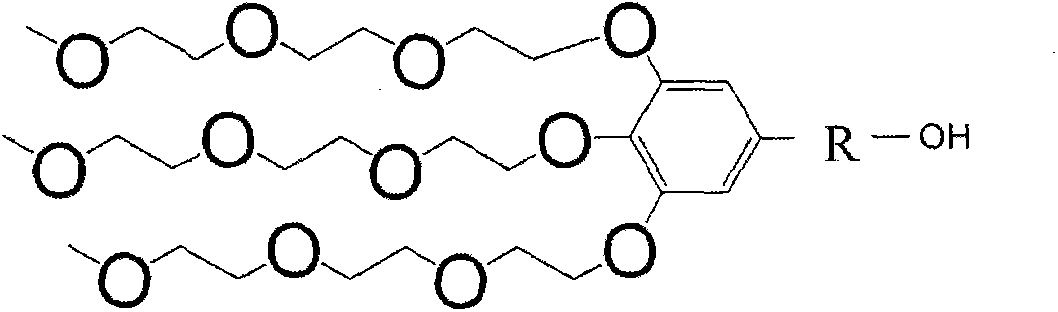

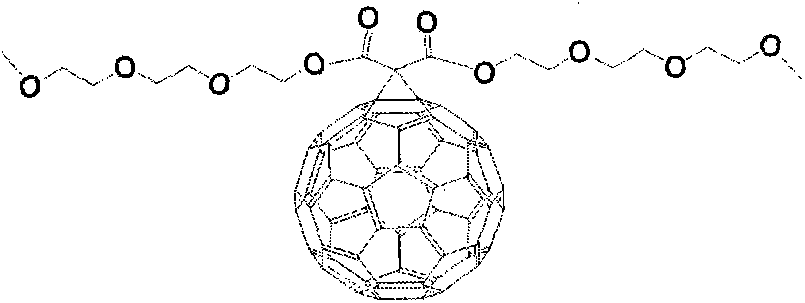

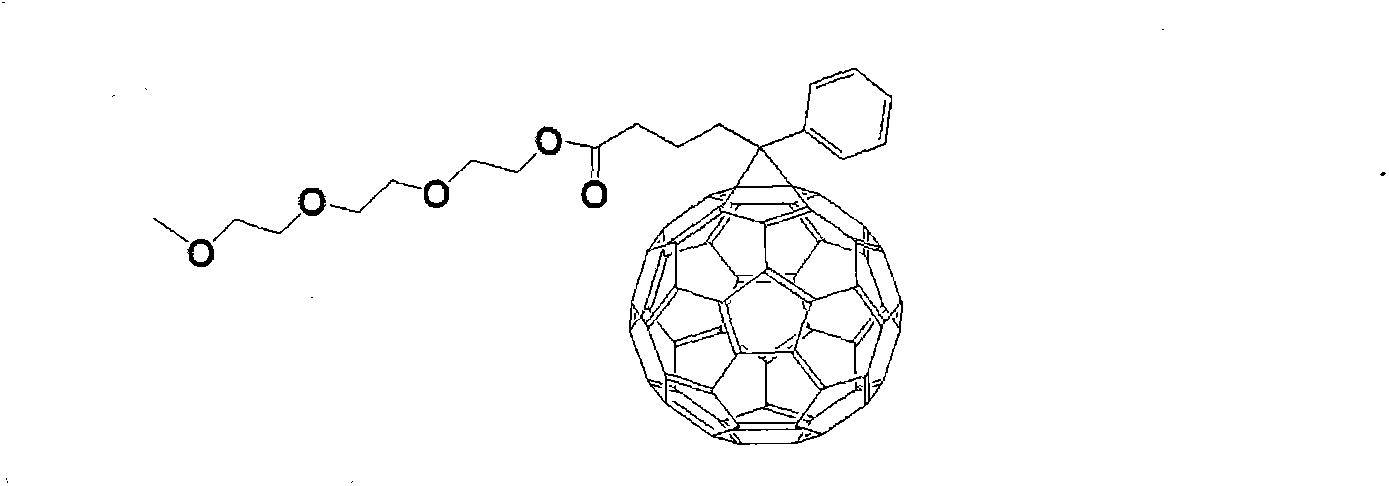

[0026] 1. In one embodiment, the C 60 (1g), 1,8-diazabicycloundec-7-ene (DBU, 0.2g), diethyl bromomalonate (0.35g) were dissolved in toluene solution (500mL), stirred at room temperature for 5 hours, use toluene as eluent to separate on silica gel chromatography to obtain molecular formula C 61 (COOCH 2 CH 3 ) 2 product of. Will C 61 (COOCH 2 CH 3 ) 2 (0.5g), p-toluenesulfonic acid (0.2g), triethylene glycol monomethyl ether (0.2g) were dissolved in toluene solution (200mL), refluxed and stirred for 24 hours, and separated by silica gel chromatography to obtain molecular formula C 61 [CO(OCH 2 CH 3 ) 3 OCH 3 ] 2 The target product, structural formula is:

[0027]

[0028] 2. In one embodiment, the C 61 [CO(OCH 2 CH 3 ) 3 OCH 3 ] 2 (0.1g) was dispersed in ethanol and water mixed solution (v / v=1: 9, 100mL), slowly added dropwise the ethanol solution of titanium tetrachloride (20g), obtained sol-gel, then dried to obtain the nanopowder of composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com