Method for preparing ultraviolet shielding textile composite fabric with graphene nanoplatelets

A technology of nano-graphene and nano-graphite, which is applied in the field of textile product manufacturing, can solve the problems of toxicity, inability to completely shield ultraviolet rays, and the stability and efficiency of anti-ultraviolet effect to be improved, and achieve easy operation, high output, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

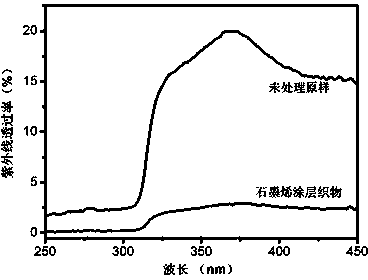

Embodiment 1

[0022] Embodiment 1: a kind of preparation method of nano-graphene microchip UV-shielding polyester sun umbrella composite fabric, comprising the following steps:

[0023] (1) Nano-graphene micro-sheet shielding agent mixing process: the nano-graphene micro-sheet solution and nano-titanium dioxide solution are shaken and dispersed, then added to the water-soluble polyurethane solution, and the mixed solution is fully stirred; the weight percentage of the raw materials is: nano-graphene 30% microchip solution, 10% nano-titanium dioxide solution, and 60% water-soluble polyurethane solution; among them, the solid content of nano-graphene microchips in the nano-graphene microchip solution is 2%, the solid content of nano-titanium dioxide is 5%, and the water-soluble polyurethane solution The solid content of polyurethane is 50%.

[0024] (2) Coating process: Coating and finishing it on the transfer coating machine. First, apply the nano-graphene microchip shielding agent on the tr...

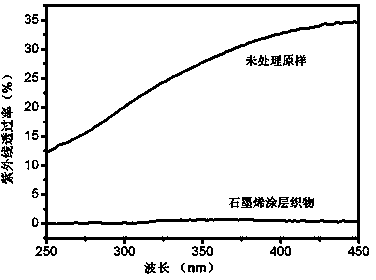

Embodiment 2

[0027] Embodiment 2: A kind of preparation method of nano-graphene microsheet ultraviolet shielding flame-retardant viscose composite tent fabric, comprising the following steps:

[0028] (1) Nano-graphene micro-sheet shielding agent mixing process: the nano-graphene micro-sheet solution and nano-titanium dioxide solution are shaken and dispersed, then added to the polyacrylate solution, and the mixed solution is fully stirred; the weight percentage of the raw material is: nano-graphene 40% microchip solution, 10% nano-titanium dioxide solution, and 50% polyacrylate solution; wherein, the solid content of nano-graphene microchips in the nano-graphene microchip solution is 2%, the solid content of nano-titanium dioxide is 10%, and polyacrylate The solid content of polyacrylate in the solution is 50%.

[0029] (2) Coating process: Coating and finishing on the transfer coating machine, firstly, the nano-graphene microplate shielding agent is coated on the transfer coating paper, ...

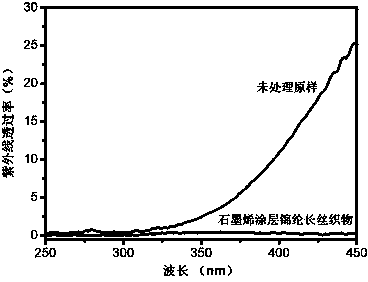

Embodiment 3

[0032] Embodiment 3: a kind of preparation method of nano-graphene microchip UV-shielding nylon filament and composite fabric thereof, comprising the following steps:

[0033] (1) Nano-graphene micro-sheet shielding agent mixing process: the nano-graphene micro-sheet solution and nano-titanium dioxide solution are shaken and dispersed, then added to the water-soluble polyurethane solution, and the mixed solution is fully stirred; the weight percentage of the raw materials is: nano-graphene 50% microchip solution, 10% nano-titanium dioxide solution, and 40% polyacrylate solution; among them, the solid content of nano-graphene microchips in the nano-graphene microchip solution is 1%, the solid content of nano-titanium dioxide is 10%, and water-soluble polyurethane The solid content of water-soluble polyurethane in the solution is 50%.

[0034] (2) Coating process: Coating and finishing on the transfer coating machine, first apply the nano-graphene microchip shielding agent on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square meter weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Square meter weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com