Nitenpyram soluble granula and preparation method thereof

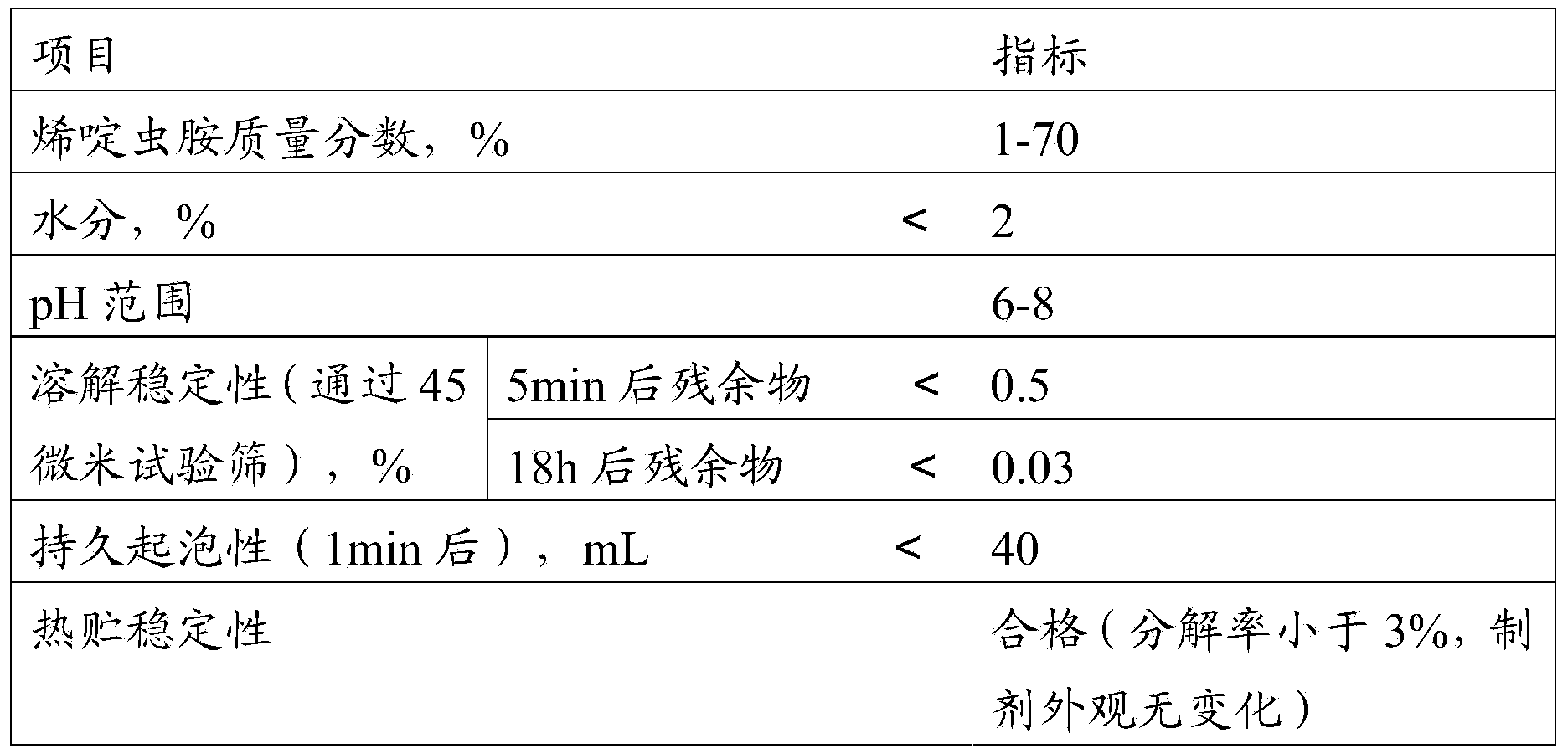

A nitenpyram and soluble technology, applied in the field of nitenpyram soluble granules and preparation thereof, can solve the problems of low melting point of nitenpyram original drug, inability to perform jet pulverization, poor flowability of the original drug, etc. Difficulty in granulation, no change in color, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

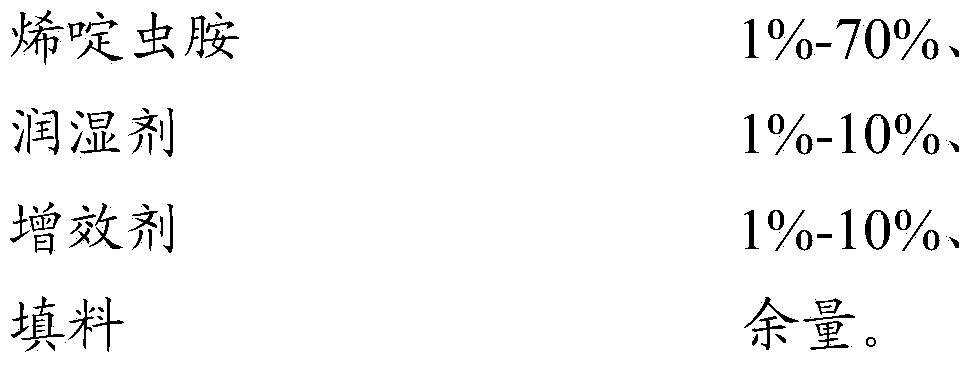

[0029] Example 1: 20% Nitenpyram Soluble Granules

[0030]Weigh 206.2 kg of 97% nitenpyram technical substance, sodium lauryl sulfate: 20 kg, tea saponin: 20 kg, ammonium sulfate to make up to 1000 kg. Mix the above-mentioned original drug, additives, and fillers uniformly, and after being pulverized by a jet mill, prepare 20% nitenpyram soluble powder, add an appropriate amount of water, mix evenly again, and granulate through a screw extrusion granulator , 50°C-65°C fluidized bed drying for 1h-2h, and sieving to obtain 20% nitenpyram soluble granules.

Embodiment 2

[0031] Example 2: 30% Nitenpyram Soluble Granules

[0032] Weigh 309.3 kg of 97% nitenpyram technical substance, LS-94 (wetting agent): 30 kg, organic silicon synergist: 30 kg, and make up to 1000 kg with sodium sulfate. Mix the above-mentioned original drug, additives, and fillers uniformly, and after being pulverized by a jet mill, prepare 30% nitenpyram soluble powder, add an appropriate amount of water, mix evenly again, and granulate through a screw extrusion granulator , 50°C-65°C fluidized bed drying for 1h-2h, and sieving to obtain 30% nitenpyram soluble granules.

Embodiment 3

[0033] Example 3: 40% Nitenpyram Soluble Granules

[0034] Weigh 412.4kg of 97% nitenpyram technical substance, WP-62: 40kg, fast penetrant T: 40kg, 200kg of sodium chloride, and make up to 1000kg of sodium sulfate. Mix the above-mentioned original medicine, additives and fillers uniformly, and after pulverization by a jet mill, prepare 40% nitenpyram soluble powder, add an appropriate amount of water, mix again uniformly, and granulate through a rotary granulator, 50 ℃-65℃ fluidized bed drying for 1h-2h, and sieving to obtain 40% nitenpyram soluble granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com