A kind of preparation method of fully substituted pyrazole containing sulfone group

A technology of fully substituted pyrazoles, which is applied in the field of preparation of fully substituted pyrazoles, can solve problems such as limited applications and complex starting material synthesis operations, and achieve the effects of reduced production costs, wide application range, and safe reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

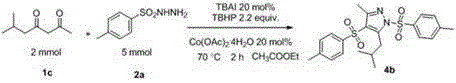

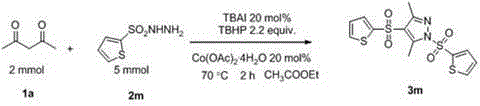

Image

Examples

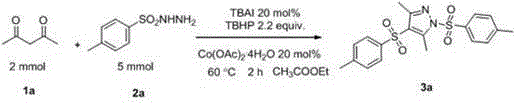

Embodiment 1

[0023]

[0024] Load TBAI (20mol%, 148mg) successively in the reaction bottle, compound 1a (2mmol, 200mg), compound 2a (5mmol, 930mg), Co(OAc) 2 . 4H 2 O (20mol%, 100mg), TBHP (0.6mL, 4.4mmol), ethyl acetate (8.0mL). Then the system was heated in the air at 70°C for about 2 hours, quenched with saturated sodium sulfite solution, extracted with ethyl acetate (40mL×3), then adsorbed with silica gel and spin-dried the solvent in vacuo, and finally washed with petroleum ether and bismuth The mixed solvent of methyl chloride is subjected to simple column chromatography to obtain the product 3a , the yield is 85%. 1 HNMR (400MHz, CDCl 3 )δ7.91–7.83(m,2H),7.76–7.70(m,2H),7.40–7.26(m,4H),2.85(s,3H),2.48–2.32(m,9H); 13 CNMR (100MHz, CDCl 3 )δ151.1, 146.6, 146.5, 144.4, 139.1, 133.8, 130.2, 129.8, 128.0, 126.6, 121.7, 21.6, 21.4, 13.6, 11.6; MS (ESI-quadrupole): Anal. Calcd. For C 19 h 21 N 2 o 4 S 2 :405,Found:405(M+H + );IR(neat,cm -1 ):υ1585, 1549, 1171, 660.

Embodiment 2

[0026]

[0027] Load TBAI (20mol%, 148mg) successively in the reaction bottle, compound 1a (2mmol, 200mg), compound 2a (5mmol, 930mg), Co(OAc) 2 . 4H 2 O (20mol%, 100mg), TBHP (0.6mL, 4.4mmol), toluene (8.0mL). Then the system was heated in the air at 70°C for about 2 hours, quenched with saturated sodium sulfite solution, extracted with ethyl acetate (40mL×3), then adsorbed with silica gel and spin-dried the solvent in vacuo, and finally washed with petroleum ether and bismuth The mixed solvent of methyl chloride is subjected to simple column chromatography to obtain the product 3a , the yield is 80%. 1 HNMR (400MHz, CDCl 3 )δ7.91–7.83(m,2H),7.76–7.70(m,2H),7.40–7.26(m,4H),2.85(s,3H),2.48–2.32(m,9H); 13 CNMR (100MHz, CDCl 3 )δ151.1, 146.6, 146.5, 144.4, 139.1, 133.8, 130.2, 129.8, 128.0, 126.6, 121.7, 21.6, 21.4, 13.6, 11.6; MS (ESI-quadrupole): Anal. Calcd. For C 19 h 21 N 2 o 4 S 2 :405,Found:405(M+H + );IR(neat,cm -1 ):υ1585, 1549, 1171, 660.

Embodiment 3

[0029]

[0030]Load KI (20mol%, 66mg) successively in the reaction bottle, compound 1a (2mmol, 200mg), compound 2a (5mmol, 930mg), Co(OAc) 2 . 4H 2 O (20mol%, 100mg), TBHP (0.6mL, 4.4mmol), ethyl acetate (8.0mL). Then the system was heated in the air at 70°C for about 2 hours, quenched with saturated sodium sulfite solution, extracted with ethyl acetate (40mL×3), then adsorbed with silica gel and spin-dried the solvent in vacuo, and finally washed with petroleum ether and bismuth The mixed solvent of methyl chloride is subjected to simple column chromatography to obtain the product 3a , the yield is 75%. 1 HNMR (400MHz, CDCl 3 )δ7.91–7.83(m,2H),7.76–7.70(m,2H),7.40–7.26(m,4H),2.85(s,3H),2.48–2.32(m,9H); 13 CNMR (100MHz, CDCl 3 )δ151.1, 146.6, 146.5, 144.4, 139.1, 133.8, 130.2, 129.8, 128.0, 126.6, 121.7, 21.6, 21.4, 13.6, 11.6; MS (ESI-quadrupole): Anal. Calcd. For C 19 h 21 N 2 o 4 S 2 :405,Found:405(M+H + );IR(neat,cm -1 ):υ1585, 1549, 1171, 660.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com