A kind of preparation method of tantalum oxynitride based non-woven fabric photocatalyst

A technology of tantalum oxynitride and catalyst is applied in the field of preparation of tantalum oxynitride-based non-woven photocatalyst, can solve the problems of high cost, complicated preparation process, complicated preparation process, etc., and achieves easy recycling and reuse, high photocatalytic activity, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

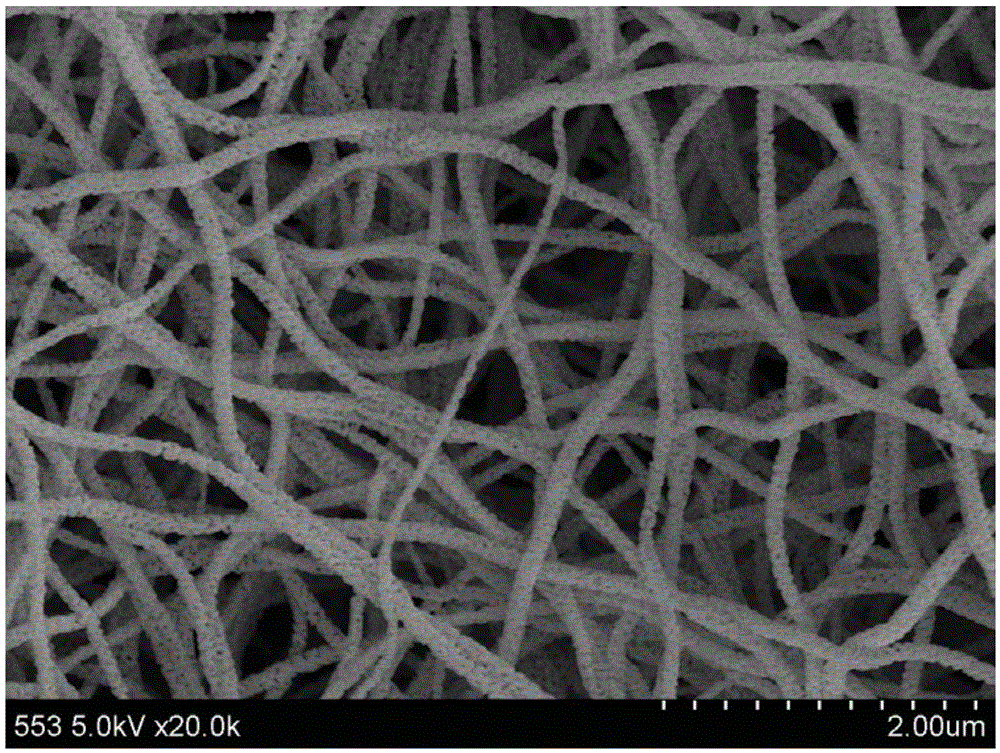

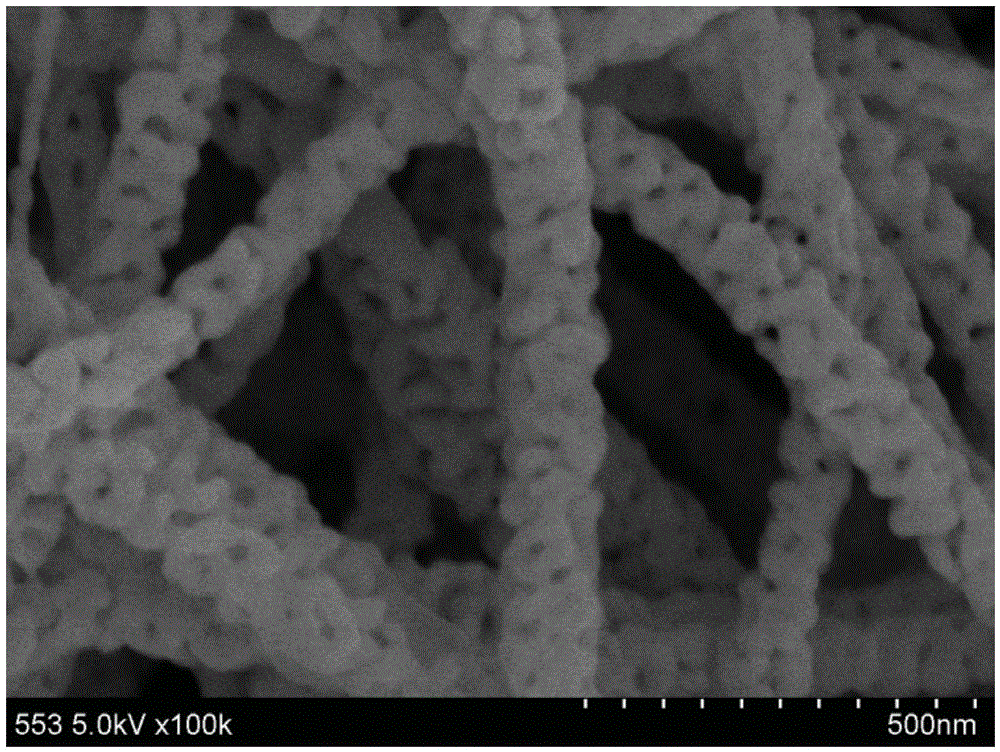

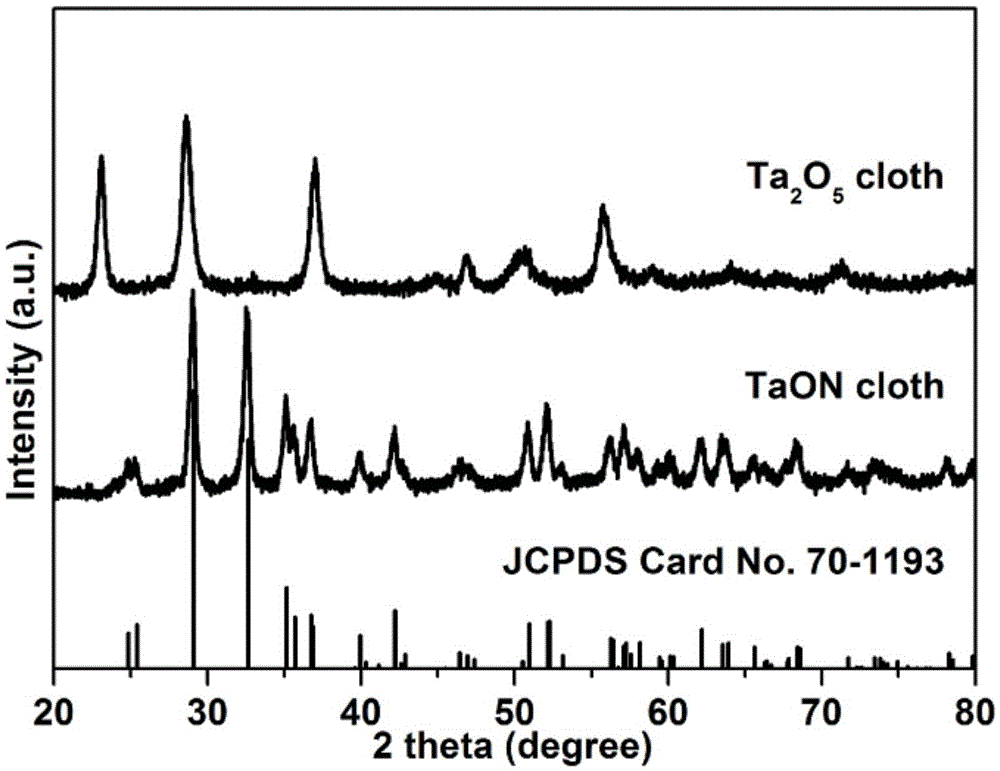

Embodiment 1

[0036] Using a sol-gel method, mix absolute ethanol and acetic acid (volume ratio 3:1), then add 8wt% PVP and 10wt% tantalum ethoxide, mix and stir for 5 hours to obtain a spinning solution. The above-mentioned spinning solution is spun, the distance between the nozzle tip and the receiver is 15cm, a DC voltage of 12,000 volts is applied, and the advancing speed of the syringe is 0.3mLh -1 . A composite polymer nonwoven fabric was obtained. Arrange the collected composite polymer nonwovens in a muffle furnace and calcinate at 600 degrees for 10 hours to obtain Ta 2 o 5 non-woven fabric. Will Ta 2 o 5 The non-woven fabric is arranged in a tube furnace for high-temperature nitriding at 800 degrees for 12 hours, and after the reaction is completed, the NH 3 Cool to room temperature under atmosphere. Among them, ammonia gas passes through a container filled with 30°C water before entering the tube furnace, and the flow rate of ammonia gas is 0.1Lmin -1 , to obtain TaON non...

Embodiment 2

[0039] Using the sol-gel method, mix absolute ethanol and acetic acid (volume ratio 4:1), then add 8wt% PVP and 10wt% tantalum ethoxide, mix and stir for 5 hours to obtain a spinning solution. The above-mentioned spinning solution is spun, the distance between the nozzle tip and the receiver is 15cm, a DC voltage of 12,000 volts is applied, and the advancing speed of the syringe is 0.3mLh -1 . A composite polymer nonwoven fabric was obtained. Arrange the collected composite polymer nonwovens in a muffle furnace and calcinate at 600 degrees for 10 hours to obtain Ta 2 o 5 non-woven fabric. Will Ta 2 o 5 The non-woven fabric is arranged in a tube furnace for high-temperature nitriding at 850 degrees for 10 hours, and after the reaction is completed, the NH 3Cool to room temperature under atmosphere. Among them, ammonia gas passes through a container filled with 30°C water before entering the tube furnace, and the flow rate of ammonia gas is 0.1Lmin -1 , to obtain TaON no...

Embodiment 3

[0043] Using a sol-gel method, mix absolute ethanol and acetic acid (volume ratio 3:1), then add 8wt% PVP and 10wt% tantalum ethoxide, mix and stir for 5 hours to obtain a spinning solution. The above-mentioned spinning solution is spun, the distance between the nozzle tip and the receiver is 15cm, a DC voltage of 12,000 volts is applied, and the advancing speed of the syringe is 0.3mLh -1 . A composite polymer nonwoven fabric was obtained. Arrange the collected composite polymer nonwovens in a muffle furnace and calcinate at 700 degrees for 10 hours to obtain Ta 2 o 5 non-woven fabric. Will Ta 2 o 5 The non-woven fabric is arranged in a tube furnace for high-temperature nitriding at 800 degrees for 10 hours, and after the reaction is completed, the NH 3 Cool to room temperature under atmosphere. Among them, ammonia gas passes through a container filled with 30°C water before entering the tube furnace, and the flow rate of ammonia gas is 0.1Lmin -1 , to obtain TaON non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com