A kind of rotating disk electric fenton reactor and its application

A turntable type reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamics water/sewage treatment, etc., can solve low aeration efficiency, insufficient aeration efficiency, transmission Quality and diffusion effects and other issues can be improved to improve the reaction degradation effect, facilitate the reaction rate, and save energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

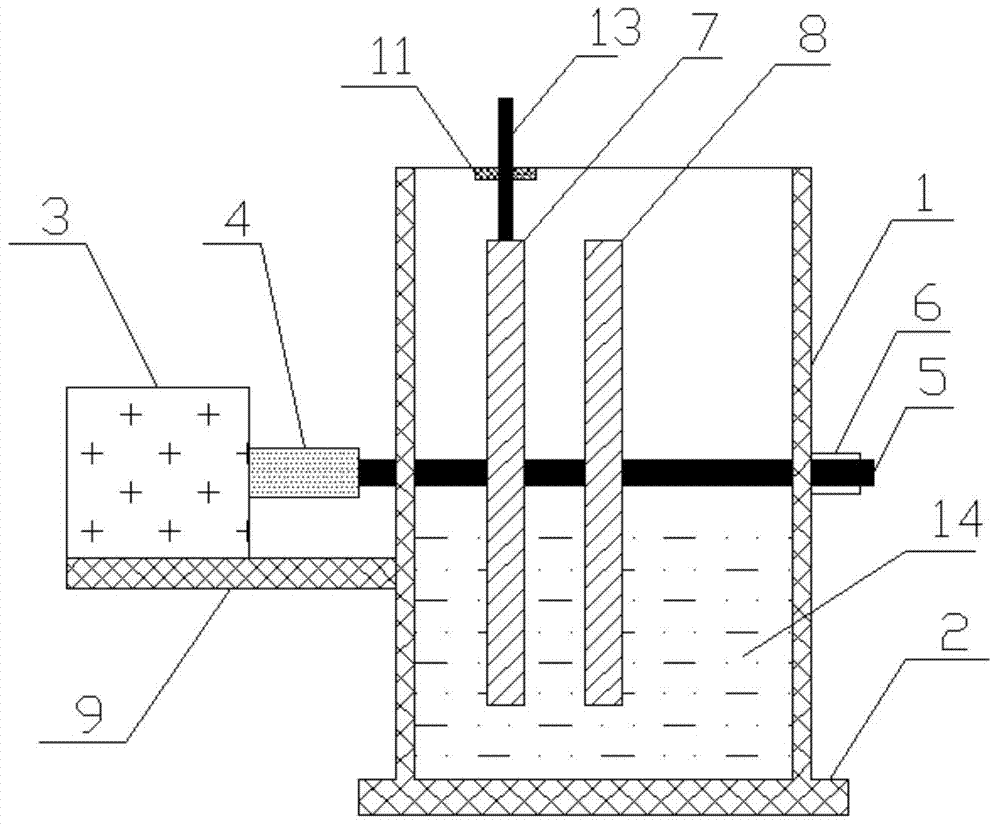

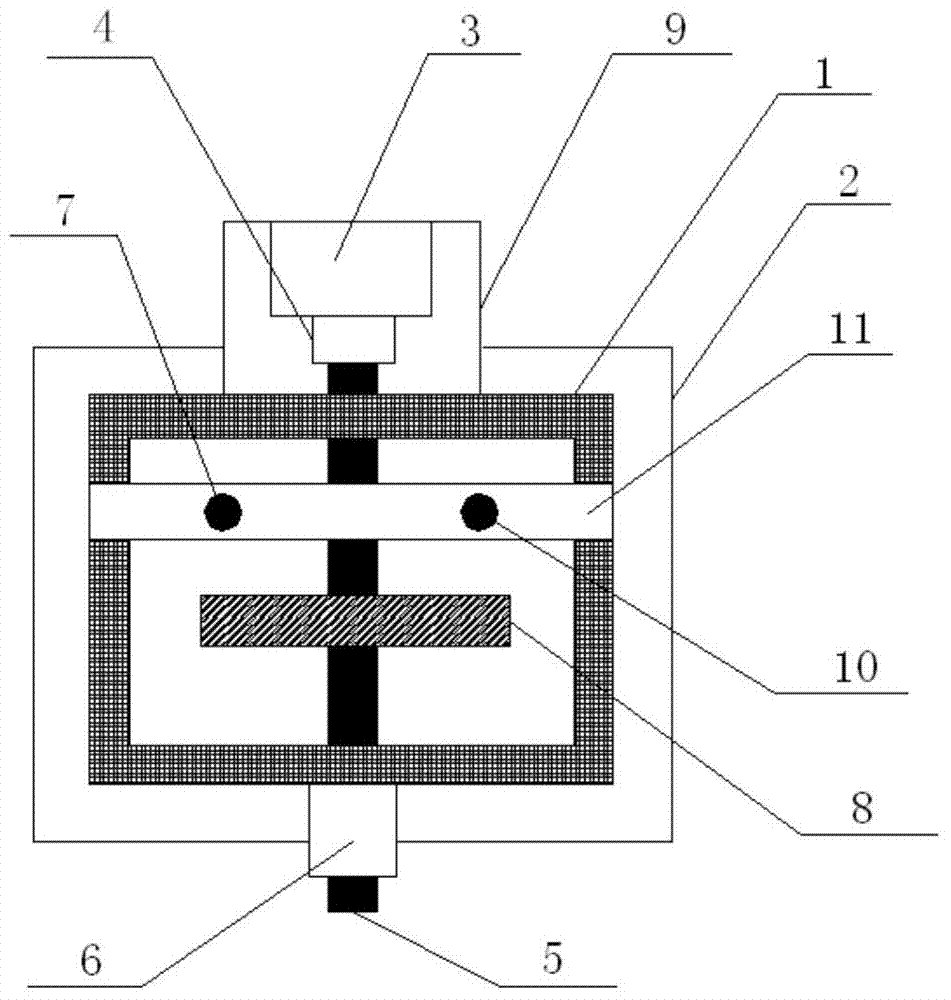

[0050] Such as Figure 1 to Figure 3 Shown, a kind of rotating disk type electric Fenton reactor comprises electrolytic reaction cell 1, graphite rotating disk electrode 8, common graphite electrode 10, saturated calomel reference electrode 7, DC motor 3, rotating shaft 5, conductive ring 6, joint Shaft device 4 and dividing plate 11, described electrolytic reaction cell 1 is set as the hollow container of a top opening, is provided with two through holes that pass through the wall on the wall of hollow container, and the center of two through holes is on the same horizontal line, Directly below one of the through holes is provided with a platform 9 on the outer surface of the connector wall. The DC motor 3 is installed on the platform 9. The DC motor 3 is fixedly connected to one end of the rotating shaft 5 through the shaft coupling 4. The other end of the rotating shaft 5 One end passes through two through holes in turn and is arranged in a conductive ring 6, the conductive...

Embodiment 2

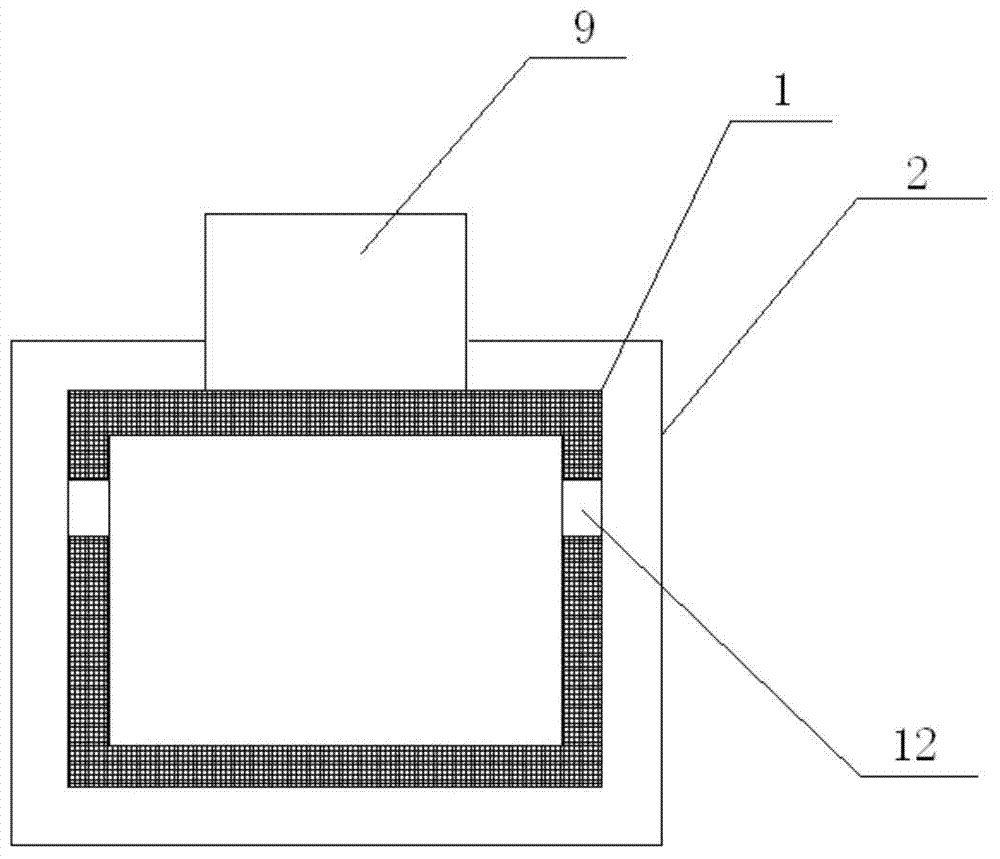

[0053] Such as figure 2 with image 3 Shown, a kind of rotating disk electric Fenton reactor, structure is as described in embodiment 1, and its difference is that partition 11 is arranged as a cuboid, and the top of electrolytic reaction cell 1 is provided with the groove 12 that accommodates partition 11 , by embedding the separator 11 in the groove 12 at the top of the electrolytic reaction cell 1, the stability of the ordinary graphite electrode 10 and the saturated calomel reference electrode 7 during the electrolytic reaction process is ensured.

Embodiment 3

[0055] Such as Figure 4 As shown, a rotating disk type electric Fenton reactor, the structure is as described in Example 1, the difference is that the edge of the graphite rotating disk electrode 8 is set in a sawtooth shape. Compared with the surface of the circumference, the serrated shape of the design increases the specific surface area of the graphite turntable electrode and increases the contact reaction area between the oxygen in the air and the water film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com