Process for improving dewaterability of excess biochemical sludge

A technology for excess sludge and dewatering performance, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of large investment, low engineering applicability, and difficult scale application and other issues to achieve the effect of improving processing capacity, shortening the fermentation cycle, and promoting rapid proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

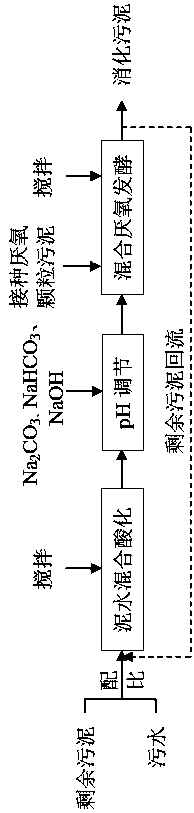

[0016] This process is used for batch treatment of excess sludge in the laboratory. The treated sludge is the remaining sludge produced by an oxidation ditch process in Zhengzhou to treat urban domestic sewage, with a moisture content of 98% and a specific resistance of 46×10 12 m / kg, the moisture content of the mud cake is 89%; the sewage to be dosed is the sewage treated by the treatment plant; the anaerobic granular sludge inoculated is taken from the IC reaction tank of a certain treatment plant. The specific steps are attached figure 1 shown.

[0017] 1) Acidification of muddy water: Mix 500mL of sludge and 500mL of sewage from the sewage treatment plant in a 1000mL beaker, and carry out hydrolytic acidification pretreatment under the condition of stirring with a six-connected mixer, the stirring speed is 70r / min, and the reaction temperature is room temperature (About 25°C), the reaction time is 6 days, samples are taken once a day, the specific resistance of the slud...

Embodiment 2

[0021] This process is used for engineering application of excess sludge. The treated sludge is the remaining sludge in the thickening tank of an oxidation ditch process in Zhengzhou to treat urban domestic sewage, with a water content of 98.5%. Sewage is treated for the treatment plant; the inoculated anaerobic granular sludge is taken from the IC reaction tank of a treatment plant. The specific steps are attached figure 1 shown.

[0022] 1) Acidification of muddy water: The remaining sludge in the thickening tank and the treated sewage are mixed into the hydrolytic acidification tank at a volume ratio of 1:1 for hydrolytic acidification until the pH is 3-4, and a submersible mixer is installed in the hydrolytic acidification tank;

[0023] 2) Adjust pH: after hydrolysis and acidification, enter the adjustment pool, use 10% NaHCO 3 Adjust the pH of the solution to 6.8-7.2;

[0024] 3) Fermentation of granular sludge: After adjusting the pH, enter the anaerobic fermentat...

Embodiment 3

[0027] This process is used for engineering application of excess sludge. The treated sludge is a certain A in Henan 2 / O process to treat the remaining sludge in the concentration tank of urban domestic sewage, the water content is 99%, and the water content of the sludge is measured to be 87.5% after direct plate and frame pressure filtration; the sewage to be distributed is the sewage treated by the treatment plant; The inoculated anaerobic granular sludge was taken from the IC reaction tank of a treatment plant. The specific steps are attached figure 1 shown.

[0028] 1) Acidification of muddy water: The remaining sludge in the thickening tank and the treated sewage are mixed into the hydrolytic acidification tank at a volume ratio of 1:1 for hydrolytic acidification until the pH is 3-4, and a submersible mixer is installed in the hydrolytic acidification tank;

[0029] 2) Adjust pH: After hydrolysis and acidification, enter the adjustment pool, use 10% Na 2 CO 3 Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com