A kind of 3D uniform porous scaffold material and preparation method thereof

A porous scaffold and uniform technology, applied in the field of biomedical materials, can solve the problems of high pore size, unfavorable vascularization, affecting cell-cell communication, etc., and achieve the effect of high porosity, good compressive strength, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

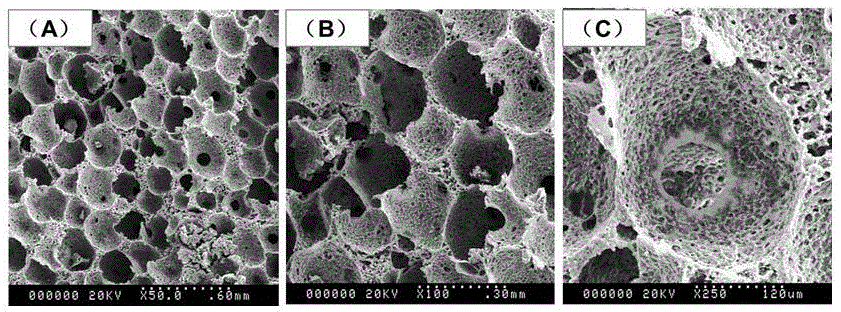

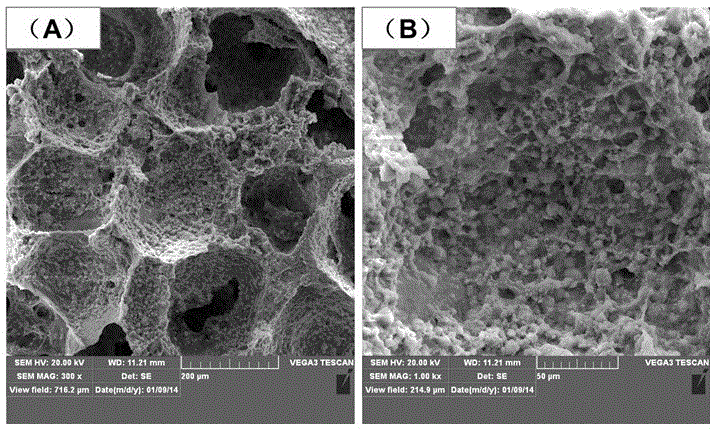

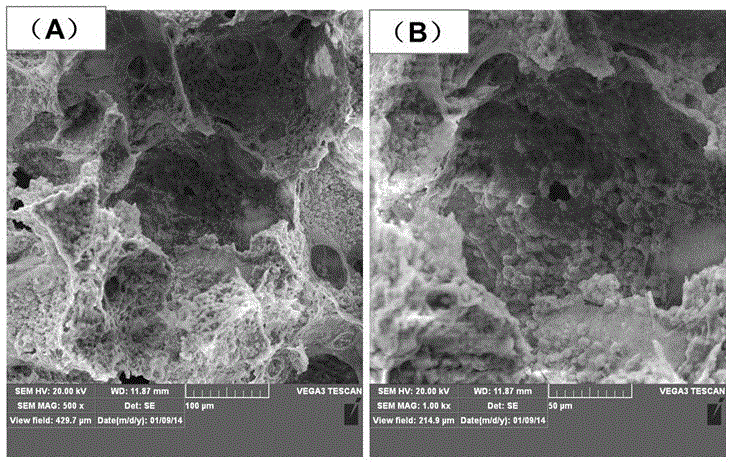

Image

Examples

preparation example Construction

[0032] A method for preparing a 3D uniform porous scaffold material, characterized in that:

[0033] Achieved by the following steps:

[0034] Step 1: Dissolving collagen in sodium carbonate solution so that the final mass fraction of collagen reaches 10-30%;

[0035] Step 2: Add nano-hydroxyapatite to the mixture in step 1, the mass ratio of collagen to nano-hydroxyapatite is 1: (3-5), shake on the vortex mixer until the mixture is uniform, and the viscosity is uniform like emulsion;

[0036] Step 3: distributing the mixture obtained in step 2 into moulds;

[0037] Step 4: The mold is frozen at -80°C for 3-6 hours, and then vacuum-dried for 48 hours;

[0038] Step 5: Carry out the cross-linking reaction of the primary freeze-dried bone scaffold material in step 4 in an excess of cross-linking agent solution. 100ml of cross-linking agent solution corresponds to 12-15g of the primary freeze-dried bone scaffold material. The pH of the system is adjusted to 8-11, the reaction...

Embodiment 1

[0050] Step 1: dissolving collagen in sodium carbonate solution so that the final mass fraction of collagen reaches 10%;

[0051] Step 2: Add nano-hydroxyapatite to the mixture in step 1. The mass ratio of collagen to nano-hydroxyapatite is 1:3. Shake on a vortex mixer until evenly mixed to obtain a viscous and uniform emulsion ;

[0052] Step 3: distributing the mixture obtained in step 2 into moulds;

[0053] Step 4: The mold is frozen at -80°C for 3 hours, and then vacuum-dried for 48 hours;

[0054] Step 5: Carry out the cross-linking reaction of the primary freeze-dried bone scaffold material in step 4 in an excessive amount of cross-linking agent solution, 100ml of cross-linking agent solution corresponds to 12g of the primary freeze-dried bone scaffold material, and use a pH regulator to adjust the pH value of the cross-linking system. The pH was adjusted to 8, the reaction temperature was 37°C, and the reaction time was 24h;

[0055] Step 6: Perform a secondary cros...

Embodiment 2

[0066] Step 1: dissolving collagen in sodium carbonate solution so that the final mass fraction of collagen reaches 20%;

[0067] Step 2: Add nano-hydroxyapatite to the mixture in step 1. The mass ratio of collagen to nano-hydroxyapatite is 1:4. Shake on a vortex mixer until evenly mixed to obtain a viscous and uniform emulsion ;

[0068] Step 3: distributing the mixture obtained in step 2 into moulds;

[0069] Step 4: The mold is frozen at -80°C for 4.5 hours, and then vacuum-dried for 48 hours;

[0070] Step 5: Carry out the cross-linking reaction of the primary freeze-dried bone scaffold material in step 4 in an excess cross-linking agent solution. 100ml of cross-linking agent solution corresponds to 13g of the primary freeze-dried bone scaffold material. The pH is adjusted to 9, the reaction temperature is 48°C, and the reaction time is 30h;

[0071] Step 6: Perform a secondary cross-linking reaction on the sample cross-linked in step 5 in an excess of cross-linking age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com