Polyacetal resin composition and preparation method thereof

A technology of polyacetal resin and composition, which is applied in the field of resin products, and can solve problems such as increased cost and reduced product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a kind of preparation method of polyacetal composition, comprises the following steps:

[0047] 100 parts of polyacetal resin, 0.001-2.0 parts of antioxidant, 0.005-3.0 parts of formaldehyde absorbent, 0.002-2.0 parts of acid absorbent, 0.001-2.0 parts of processing stabilizer, 0.1-20 parts of modified inorganic filler, 0.005 ~2.0 parts of dispersant are melted and kneaded to obtain a polyacetal composition; the dispersant is mineral oil, oligoolefin, C12-C20 fatty acid, dimethyl polysiloxane and hydrogen, phenyl, halogenated One or more of the dimethyl polysiloxanes obtained by substituting methyl groups with phenyl groups, haloalkyl groups, and fluoroester groups;

[0048] The modified inorganic filler is obtained by modifying the inorganic filler and a modifier under the conditions of a rotating speed of 500-10,000 rpm and a temperature of 10-100°C.

[0049] According to the present invention, after mixing various raw materials, t...

Embodiment 1

[0058] 100 parts by weight of paraformaldehyde and 3.5 parts by weight of 1,3-dioxolane as comonomer in BF 3 - Polymerize in the presence of an ether catalyst, use methylal as a chain transfer agent, then deactivate the catalyst with a triethylamine solution to obtain a polyoxymethylene copolymer, and the melt index of its melt (measured at 190 ° C under 2.16 kg) is 2.0-30.0g / 10min.

Embodiment 2

[0060] The modification speed is 3000 rpm, the modification temperature is 50° C., and the addition amount of isopropyl tris(dodecylbenzenesulfonyl) titanate is 2.0% of the weight of calcium carbonate to obtain modified calcium carbonate.

[0061] Add 0.4 parts by weight of tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester to 100 parts by weight of polyoxymethylene polymer prepared in Preparation Example 1, 0.2 The melamine of weight part, the calcium stearate of 0.1 weight part, 0.2 weight part of pentaerythritol stearate, 5 weight parts of above-mentioned modified calcium carbonates, 0.5 weight part of dimethyl siloxane, fully mix, then at 10KPa reduce Under pressure conditions, at 210°C, use a twin-screw extruder with a vent port to melt and mix for 0.5 minutes, then pelletize and shape, and dry the pellets at 140°C for 3 hours to obtain a stabilized polyacetal composition.

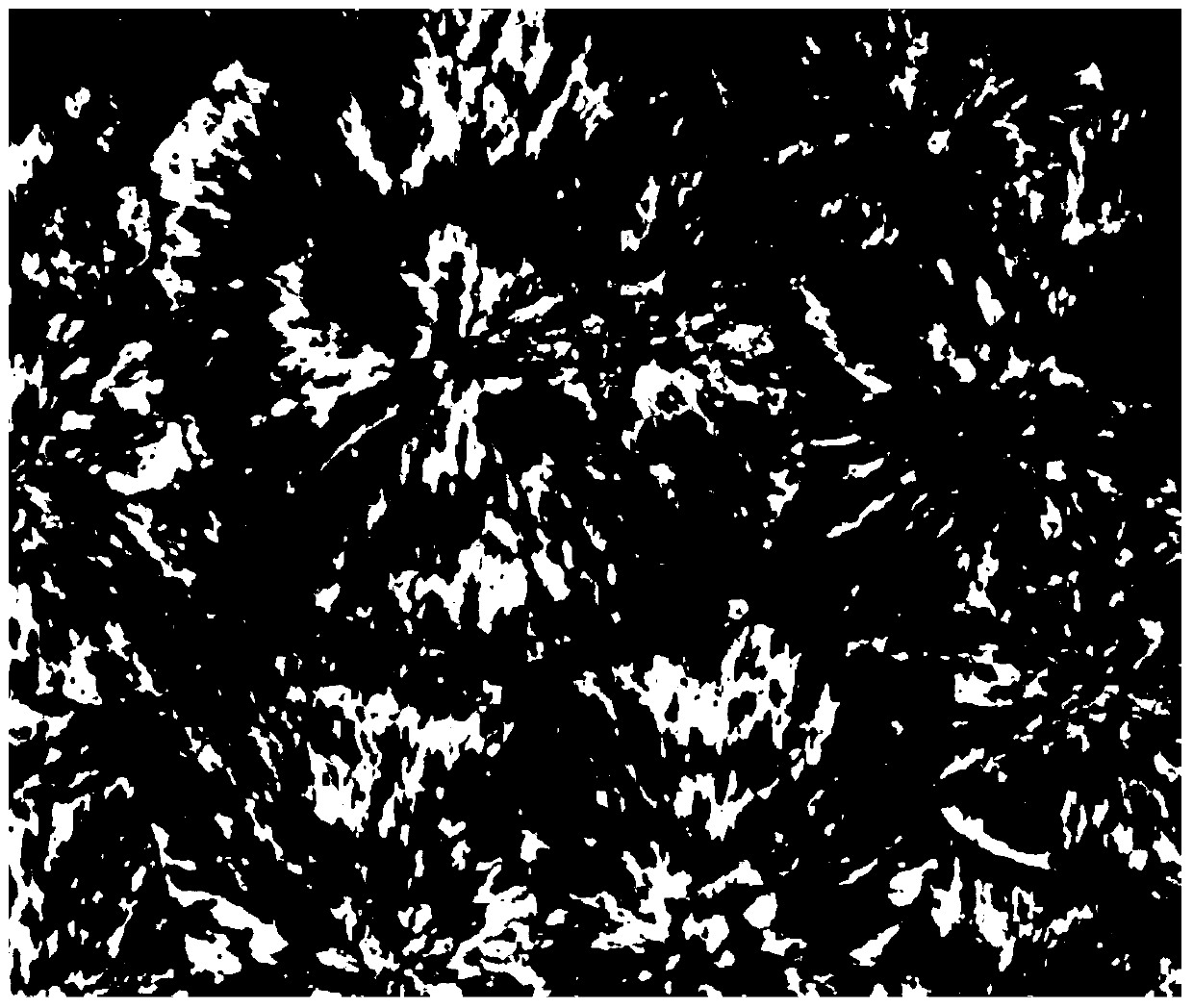

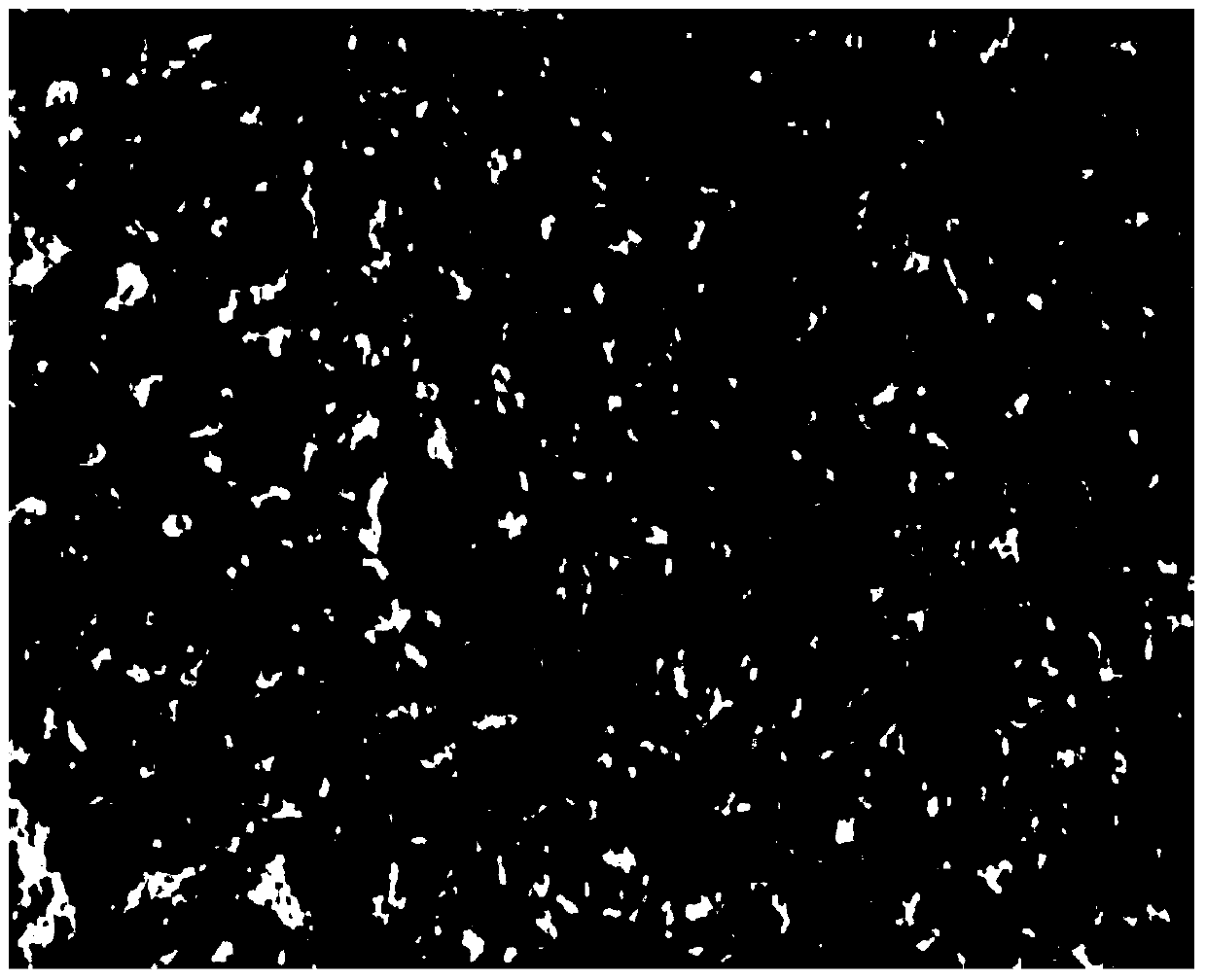

[0062] figure 1 For the polarized picture of the polyacetal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com