Bone tissue engineering composite porous scaffold material and preparation method thereof

A technology of bone tissue engineering and porous scaffolds, applied in medical science, prostheses, etc., can solve the problems of difficult storage and high cost of bone repair substitutes, and achieve low cost, excellent osteoconduction and induction performance, and good biological activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

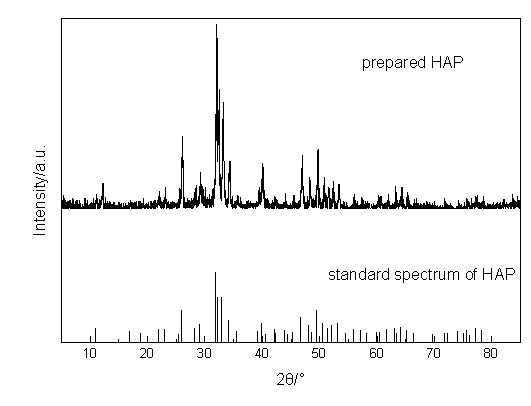

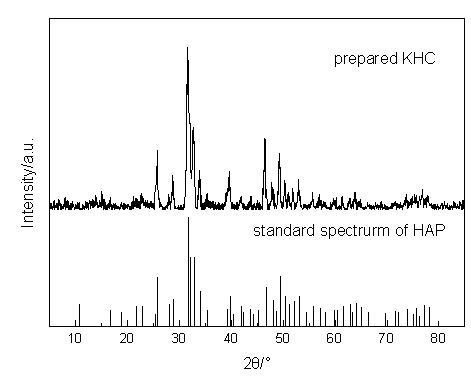

[0032] Implementation mode one: if figure 1 and 2 As shown, the composite bone tissue engineering porous scaffold material finally prepared in this embodiment consists of konjac glucomannan, chitosan and nano-hydroxyapatite in a mass ratio of 1:1.07:4.62, with a porosity of 91.72%. The compressive strength is 0.17MPa. The specific preparation method is:

[0033] (1) Use a measuring cylinder to measure 50ml of distilled water and place it in a small beaker with a capacity of 50ml, add 4.26g of nano-hydroxyapatite and stir to fully dissolve to obtain solution A;

[0034] (2) Add 0.99g chitosan to solution A, mix and stir evenly to obtain mixed suspension B;

[0035] (3) Extract 0.097ml analytically pure ammonia water with a micro-injector, add it to the suspension B, and stir thoroughly to obtain an alkaline solution C;

[0036] (4) Add 0.92g konjac glucomannan to C at a constant speed, and take out the stirring bar quickly after 2-3 seconds after the stirring vortex disappe...

Embodiment approach 2

[0041] Embodiment 2: The composite bone tissue engineering porous scaffold material finally prepared in this embodiment consists of konjac glucomannan, chitosan and nano-hydroxyapatite in a mass ratio of 1:0.54:2.31, with a porosity of 90.28% , The compressive strength is 0.21MPa. Specific steps include:

[0042] (1) Use a graduated cylinder to measure 50ml of distilled water and place it in a small beaker with a capacity of 50ml, add 4.26g of nano-hydroxyapatite and stir to fully dissolve it to obtain solution A;

[0043] (2) Add 0.99g chitosan to solution A, mix and stir evenly to obtain mixed suspension B;

[0044] (3) Extract 0.19ml of analytically pure ammonia water with a micro-sampler, add it to the suspension B, and stir thoroughly to obtain an alkaline solution C;

[0045] (4) Add 1.84g of konjac glucomannan to C at a constant speed, and after 2~3 seconds after the stirring vortex disappears, quickly take out the stirring bar to obtain gel D;

[0046] (5) Put the sma...

Embodiment approach 3

[0050] Embodiment 3: The components of the composite bone tissue engineering porous scaffold material finally prepared in this embodiment are composed of three raw materials: konjac glucomannan, chitosan and nano-hydroxyapatite, and chitosan / konjac glucoman The polysaccharide (mass ratio) is 0.36 / 1, the nano-hydroxyapatite / konjac glucomannan (mass ratio) is 1.54 / 1, the porosity is 88.30%, and the compressive strength is 0.25MPa.

[0051] (1) Measure 50ml of distilled water with a graduated cylinder and place it in a small beaker with a capacity of 50ml, add 4.26g of nano-hydroxyapatite and stir to fully dissolve it to obtain solution A;

[0052] (2) Add 0.99g chitosan to solution A, mix and stir evenly to obtain mixed suspension B;

[0053] (3) Extract 0.29ml of analytically pure ammonia water with a micro-injector, add it to the suspension B, and stir thoroughly to obtain an alkaline solution C;

[0054] (4) Add 2.77g of konjac glucomannan to C at a constant speed, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com