Method for processing flexible OLED through printing micromolecule ink technology

A technology of small molecules and inks, applied in the field of organic electroluminescent display devices, can solve the problems of long production time, high price of OLED displays, and difficulty in guaranteeing product yield, so as to improve the luminous efficiency and lifespan, and facilitate printing. Processing technology, the effect of processing technology simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An organic electroluminescence display device, comprising a 30×30mm silver nanowire coated 2 The PET board is used as the anode, the hole injection layer, the hole transport layer, the light emitting layer and the LiF / Al cathode are laminated in sequence.

[0039] Hole injection layer: the ratio of PEDOT:PSS aqueous solution doped with water is 1:99, and the ratio of PEDOT:PSS is 1:15. Add proper amount of surfactant 3,4-ethylidene dioxythiophene, adjust its rheological parameters, surface tension: 25-40mN / m, apparent viscosity 10-14mPa·s. The PEDOT:PSS ink is deposited on the substrate by inkjet printing. Use Spectra Galaxy PH256 / 50AAA inkjet head. Nozzle pitch is 254 microns, ink drop volume is 50pl. The stable satellite-free droplets are formed by adjusting the electric pulse and driving voltage. The thickness of the hole injection layer is 100 nm.

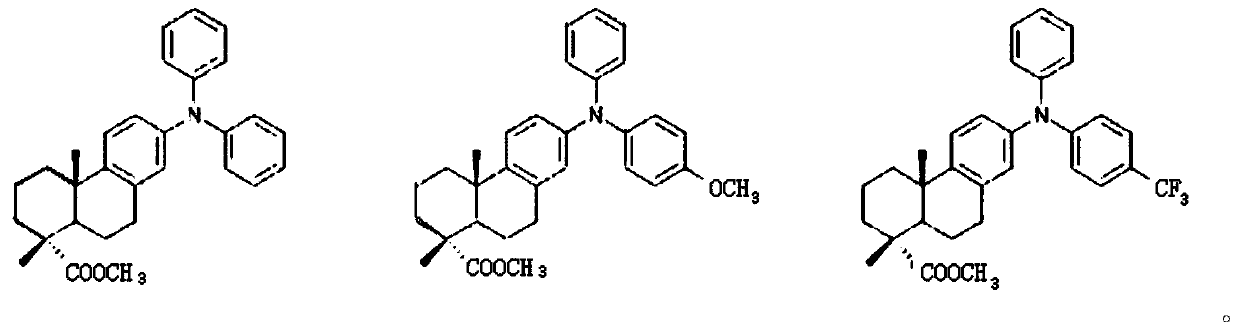

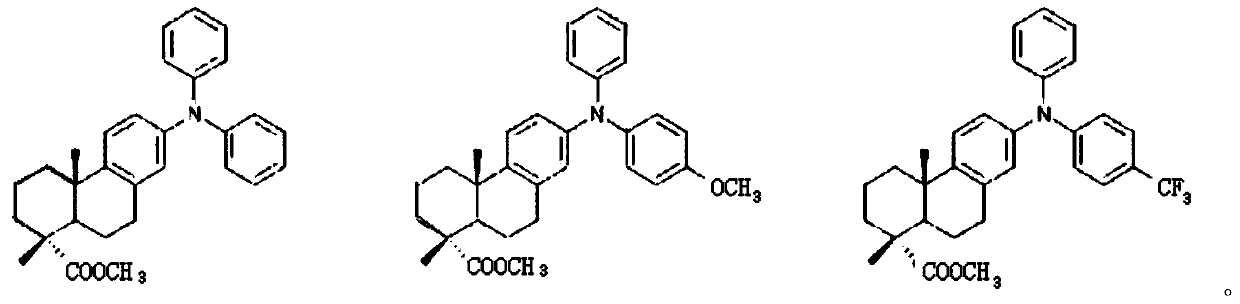

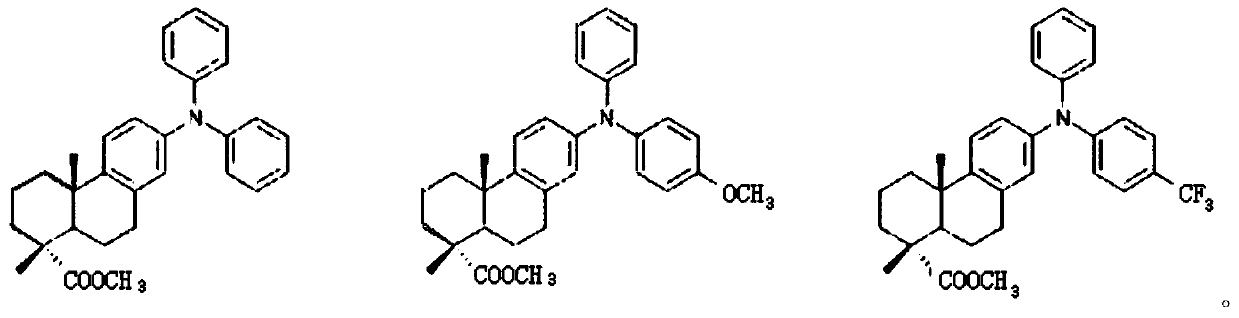

[0040] Hole transport layer: lipophilic cross-linkable phenolic resin and aromatic amine compound with a molecular weigh...

Embodiment 2

[0046] A method for processing flexible OLED by printing small molecule ink technology. The steps at least include preparing a hole injection layer, a hole transport layer and a light-emitting layer, in order: first PEDOT:PSS, then the hole transport layer, and then the light-emitting layer . According to the conventional method, a cathode and an anode are prepared on both sides of the membrane.

[0047] Among them, the preparation of the hole injection layer:

[0048] Step 1.1. Use hydrophilic PEDOT:PSS particle ink as raw material to be doped with water in proportion to the requirements, and add surfactant to adjust the rheological parameters of the mixed solution to prepare the ink material of the hole injection layer;

[0049] Step 1.2. Since the OLED display requires a specific coating pattern, the hole injection layer coating pattern is generated by the non-contact coating in the early stage and the laser elimination method or the direct inkjet printing method in the later sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com