Method for preparing lithium-rich cathode materials by sol-gel self-propagating combustion method

A lithium-rich positive electrode material, self-propagating combustion technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of poor conductivity and poor rate performance of materials, and achieve short diffusion path, small particle size, easy operation and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

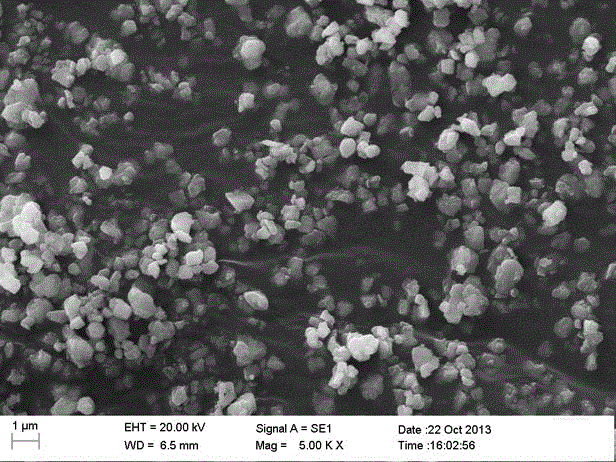

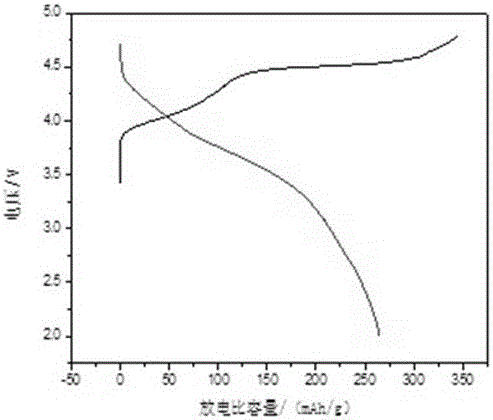

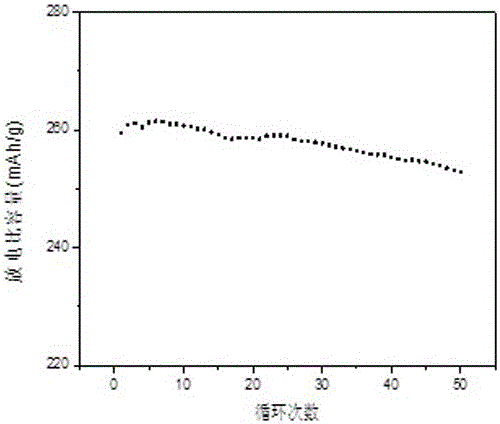

[0031] Preparation of lithium-rich cathode materials Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 According to the stoichiometric ratio of Li, Ni and Mn elements in the target product, accurately weigh the corresponding lithium nitrate, nickel nitrate and manganese acetate, according to the total mass of metal salt: ethanol mass = 1:8, prepare the solution, and stir at room temperature Dissolved at 80 o C, carry out mechanical stirring and evaporation in a constant temperature water bath, transfer it to a crucible after it becomes a gelatinous transparent substance, place the crucible in a muffle furnace and burn it at 350°C for 1 hour, so that a self-propagating combustion reaction occurs, and the burned The ashes were ground and placed in a muffle furnace for calcination at 850°C for 16h in an oxygen atmosphere. Grind and pass through a 400-mesh sieve to obtain Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 Cathode material.

[0032] The synthesized Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 The p...

Embodiment example 2

[0034] Preparation of lithium-rich cathode materials Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 According to the stoichiometric ratio of Li, Ni and Mn in the target product, accurately weigh the corresponding lithium acetate, nickel acetate and manganese acetate, and prepare the solution according to the total mass of metal salt: mass of ethanol = 1:9, and stir at room temperature Add magneton after dissolving, set at 90 oC, conduct magnetic stirring and evaporation in a constant temperature water bath, transfer it to a crucible after it becomes a colloidal transparent substance, place the crucible in a muffle furnace and burn it at 400°C for 0.5h to make it undergo a self-propagating combustion reaction, and burn The final ashes were ground and calcined at 900°C for 12 hours in a muffle furnace under an oxygen atmosphere. Grind and pass through a 400-mesh sieve to obtain Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 Cathode material.

[0035] The synthesized Li (Li 0.08 Ni 0.38 mn 0.54 ...

Embodiment example 3

[0037] Preparation of lithium-rich cathode materials Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 According to the stoichiometric ratio of each element of Li, Ni and Mn in the target product, accurately weigh the corresponding lithium nitrate, nickel acetate and manganese nitrate, and prepare the solution according to the total mass of metal salt: mass of ethanol = 1:10, and stir at room temperature Dissolved at 75 o Stir and evaporate in a constant temperature water bath, transfer it to a crucible after it becomes a colloidal transparent substance, place the crucible in a muffle furnace and burn it at 350°C for 2 hours to make it undergo a self-propagating combustion reaction, and the burned The ashes were ground and calcined at 800°C for 24 hours in a muffle furnace under an oxygen atmosphere. Grind and pass through a 400-mesh sieve to obtain Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 Cathode material.

[0038] The synthesized Li (Li 0.08 Ni 0.38 mn 0.54 )O 2 The positive electrode m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com