Neodymium iron boron magnetic material with composite coating layer and preparation method for neodymium iron boron magnetic material

A technology of magnetic materials and composite coatings, applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve problems such as aluminum nitride and silicon carbide composite coatings that have not been seen, and reduce internal stress. , prolong the service life, the effect of strong bonding force of the membrane base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

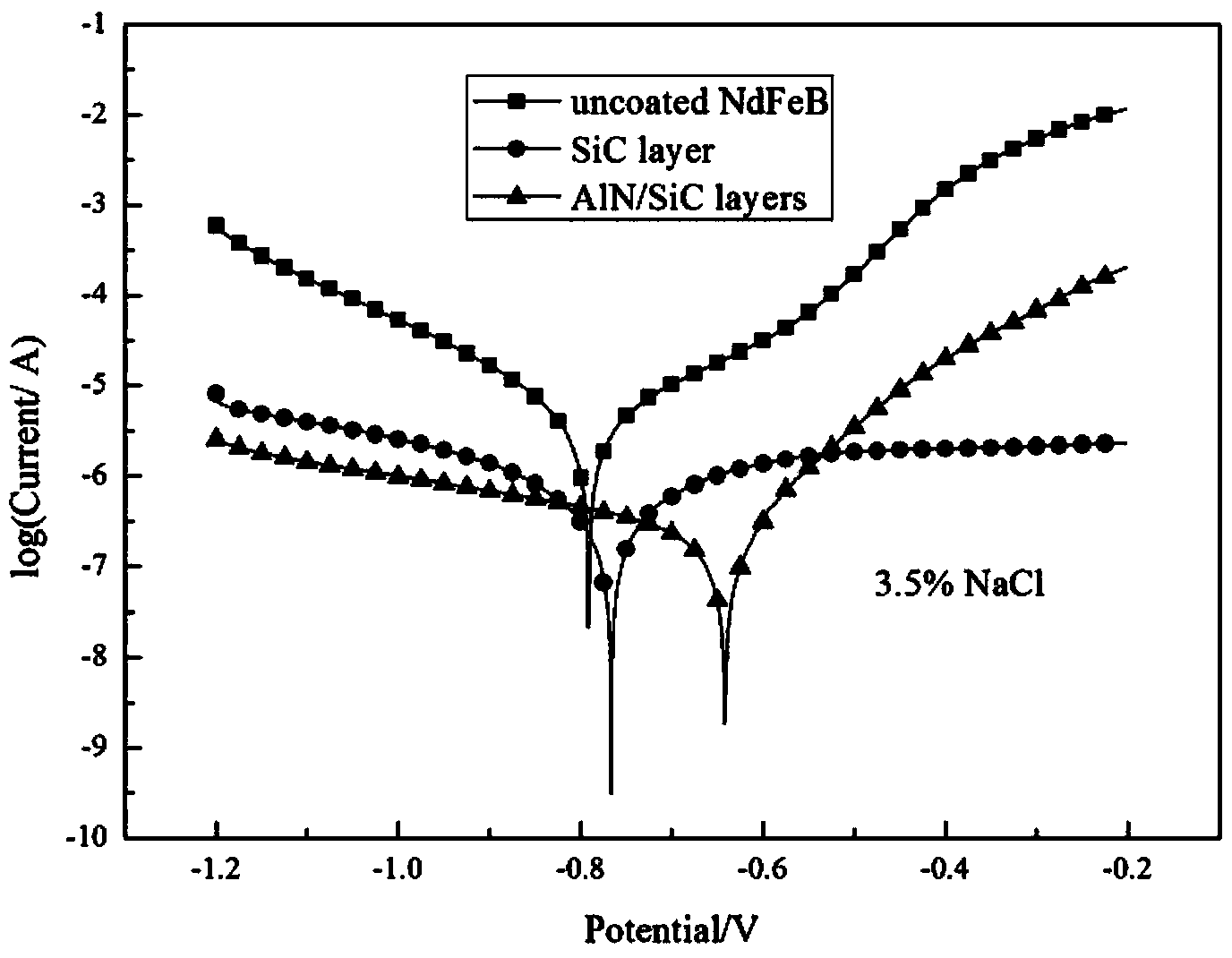

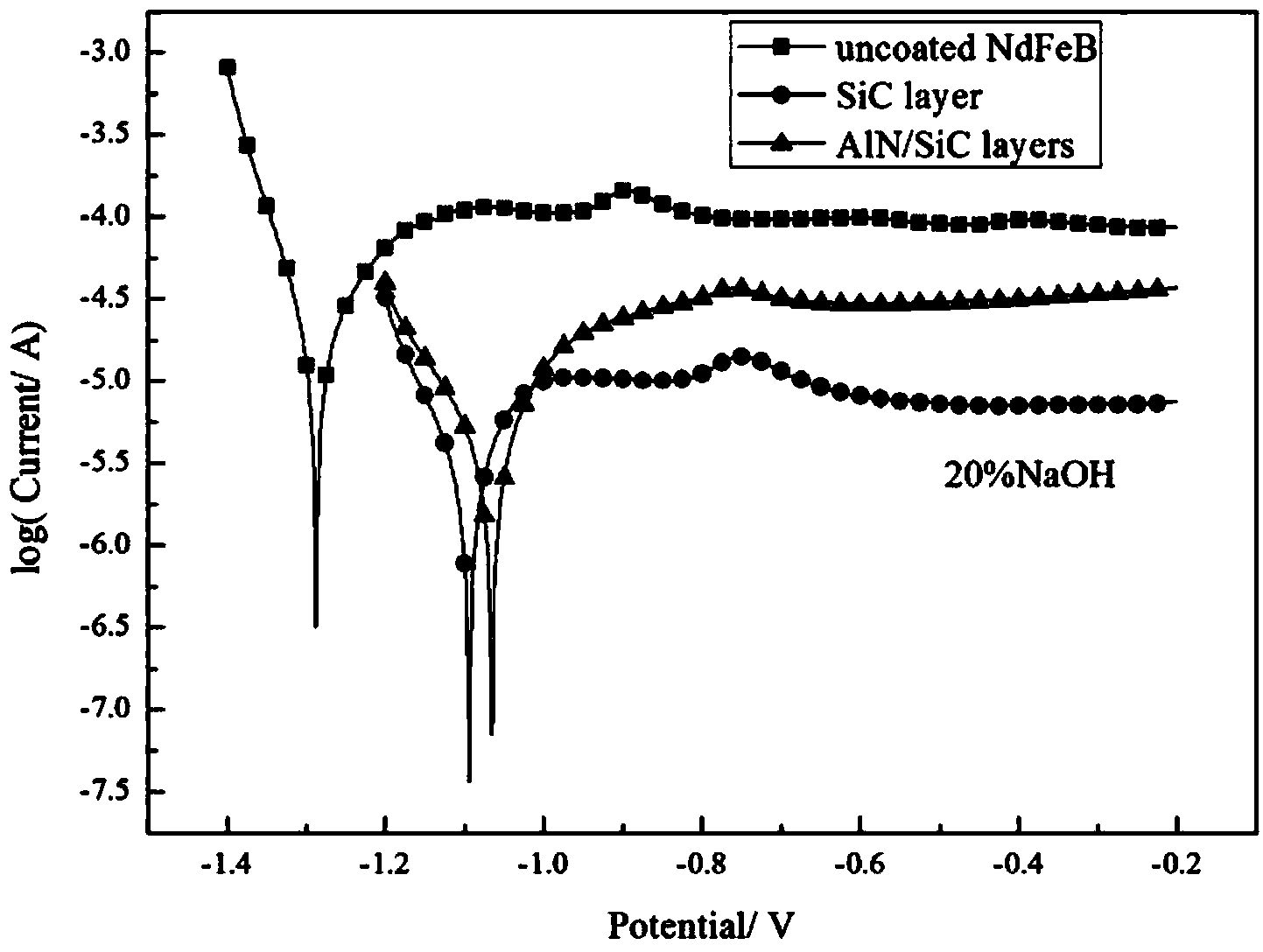

[0023] Preparation of aluminum nitride and silicon carbide composite coating on the surface of NdFeB magnetic material:

[0024] (1) Grind the surface of the NdFeB magnetic material with 400 mesh, 500 mesh, 600 mesh, and 800 mesh sandpaper from coarse to fine; then perform mechanical polishing. Mechanical polishing refers to grinding the The material is polished with diamond paste on a rotating polishing disc covered with flannelette; finally, the surface is cleaned, and the cleaning conditions are: ultrasonic cleaning with acetone and alcohol for 20 minutes respectively.

[0025] (2) Vacuum aluminum nitride plating: put the prepared magnet and target into the chamber, and vacuum the coating chamber through a mechanical pump and a molecular pump. When the background vacuum of the vacuum chamber reaches 2.0×10 -4 At Pa, Ar (flow rate: 20sccm) is introduced as the sputtering gas, the pressure is 0.5Pa, the power is 100W, after pre-sputtering for 15 minutes, N 2 (flow rate 10scc...

Embodiment 2

[0029] (1) Grind the surface of the NdFeB magnetic material with 400 mesh, 500 mesh, 600 mesh, and 800 mesh sandpaper from coarse to fine; The material is polished with diamond paste on a rotating polishing disc covered with flannelette; finally, the surface is cleaned, and the cleaning conditions are: ultrasonic cleaning with acetone and alcohol for 10 minutes respectively.

[0030] (2) Vacuum aluminum nitride plating: put the prepared magnet and target into the chamber, and vacuum the coating chamber through a mechanical pump and a molecular pump. When the background vacuum of the vacuum chamber reaches 2.0×10 -4 At Pa, Ar (flow rate: 20sccm) is introduced as the sputtering gas, the pressure is 0.5Pa, the power is 100W, after pre-sputtering for 15 minutes, N 2 (flow rate 10sccm) as reaction gas, carry out 1 hour aluminum nitride plating to magnet, take out the neodymium iron boron magnetic material of aluminum nitride plating;

[0031] (3) Vacuum silicon carbide plating: Pu...

Embodiment 3

[0034] The preparation method of this embodiment is as embodiment 1, embodiment 2. The vacuum-coated aluminum nitride film on the surface of the prepared NdFeB magnetic material has a thickness of 100 nm, and the silicon carbide film has a thickness of 400 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com