A kind of continuous preparation method and equipment of aluminum nitride powder

A technology of aluminum nitride powder and alumina, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., to achieve the effects of small footprint, prolong life, and ensure uniformity and consistency of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

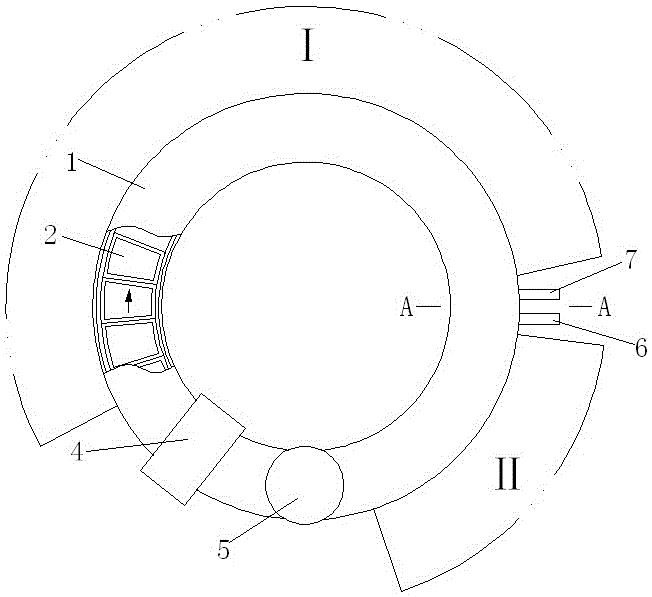

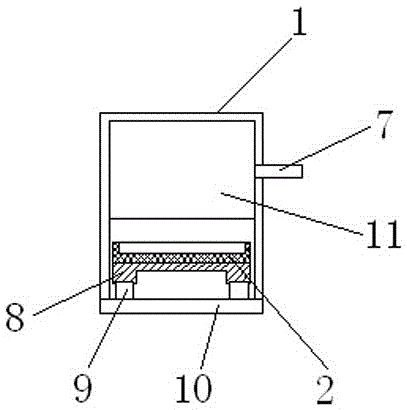

[0025] like figure 1 , 2 The continuous production equipment for the production of aluminum nitride powder shown in , 3 is equipped with a heating device and an annular track 9 on the furnace bottom 10 of the annular closed furnace body 1 of the rotary hearth type annular graphite resistance furnace, and a material is installed on the annular track. The boat 2, the material boat is driven by the power unit 8 to move on the circular track. In the annular closed furnace body of the rotary bottom-type annular graphite resistance furnace, it is divided into reduction nitriding area I and carbon removal area II. The arc angle of the reduction nitriding area is greater than or equal to 180°, and the arc angle of the carbon removal area is less than It is equal to 90°. A silo 4 and a suction collector 5 are installed on the annular closed furnace body between the reduction nitriding area and the carbon removal area. A vibration or screw feeding device is installed on the outlet of t...

Embodiment 2

[0032] On the basis of Example 1, aluminum nitride seeds are added to the mixed abrasive, the amount of which is about 1% of the total weight of the raw materials composed of aluminum oxide and carbon black, and the atmosphere of the mixed abrasive is kept under the protection of nitrogen. Carry out, wherein the purity of alumina and carbon black is more than 99.9%, other technical parameters remain unchanged.

Embodiment 3

[0034] According to the user's requirements for aluminum nitride powder, yttrium oxide is added in the raw material mixing step. The amount of yttrium oxide added is 3.5% of the total weight of the raw material composed of aluminum oxide and carbon black. The purity of the added yttrium oxide is 99.9%, and the rest The technical parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com