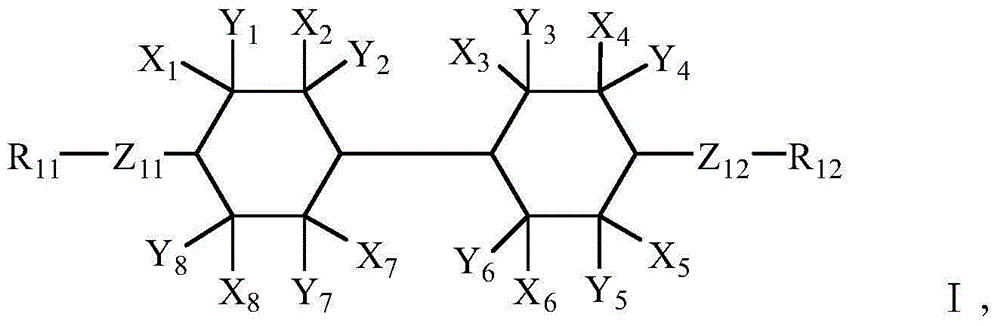

Cyclohexane liquid crystal compound and liquid crystal compound

A technology for liquid crystal compounds and liquid crystal compositions, applied in liquid crystal materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of slow response speed of liquid crystal compositions, unable to fully meet the display requirements of liquid crystal display elements, etc., and improve the response time. , the effect of reducing the rotational viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

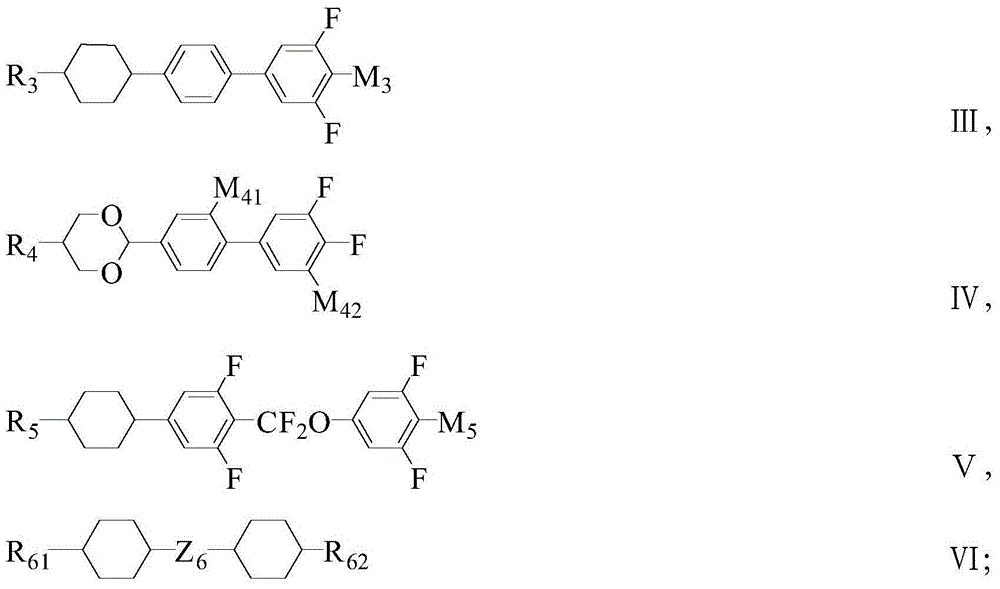

[0065] The preparation method of the liquid crystal compound shown in the formula I-1 is:

[0066]

[0067] Wherein, step A is a SUZUKI coupling reaction, and step B is a catalytic hydrogenation reaction.

[0068] The liquid crystal compounds represented by the formulas I-2 to I-5 can be prepared by selecting corresponding raw materials and referring to the above-mentioned methods.

[0069] The liquid crystal compound represented by the formula I-6 is preferably a liquid crystal compound represented by the formula I-6-1 ~ formula I-6-4:

[0070]

[0071] The preparation method of the liquid crystal compound shown in the formula I-6 is:

[0072]

[0073] Wherein, step a is an α-alkylation reaction; step b is a fluorination reaction, and the fluorinating agent used is diethylaminosulfur trifluoride (DAST).

[0074] A liquid crystal composition with positive dielectric anisotropy, comprising 2-40 parts by mass of the first component, 30-90 parts of the second component...

Embodiment 1

[0094] Preparation of cyclohexane liquid crystal compound Ⅰ-1-1:

[0095] Its synthetic route is:

[0096]

[0097] Concrete preparation process is as follows:

[0098] Step A:

[0099] Add 9.3g (0.05mol) of 4-ethyl-2,3-difluorophenylboronic acid, 11.9g (0.06mol) of 1-bromo-4-propylbenzene, 6.36g (0.06mol) of anhydrous sodium carbonate into a 500ml three-necked flask mol), toluene 100ml, ethanol 75ml and water 75ml, after heating to reflux, add catalyst tetraphenylphosphine palladium 0.25g (0.0002mol), and then keep reflux reaction for 6h; layer; the organic phase is first passed through a silica gel column, and then recrystallized with 2 times of ethanol to obtain 13g white crystals, which are intermediates

[0100] Step B:

[0101] Add 13g (0.05mol) of the above-mentioned intermediate, 2g Raney nickel catalyst, and 200ml ethanol to a 500ml autoclave, pass hydrogen until the pressure of the autoclave is 3.5-4Mpa, and carry out high-pressure hydrogenation reaction a...

Embodiment 2

[0105] Preparation of cyclohexane liquid crystal compounds Ⅰ-1-2~Ⅰ-1-5:

[0106] The same as the preparation method of compound I-1-1 in Example 1, the difference is: the reaction raw materials used are different,

[0107] The raw materials for preparing compound Ⅰ-1-2 are:

[0108] The raw material for preparing compound Ⅰ-1-3 is:

[0109] The raw material for preparing compound Ⅰ-1-4 is:

[0110] The raw material of preparation compound Ⅰ-1-5 is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com