High-temperature-resistance flame-retardant glass fiber reinforced PA46/PA66 composite material and preparation method thereof

A flame retardant glass fiber, PA66 technology, applied in the field of polymer composite material preparation, can solve the problems of limited large-scale application, only flame retardant performance, high price, etc., and achieve the effects of convenient production, simple process and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

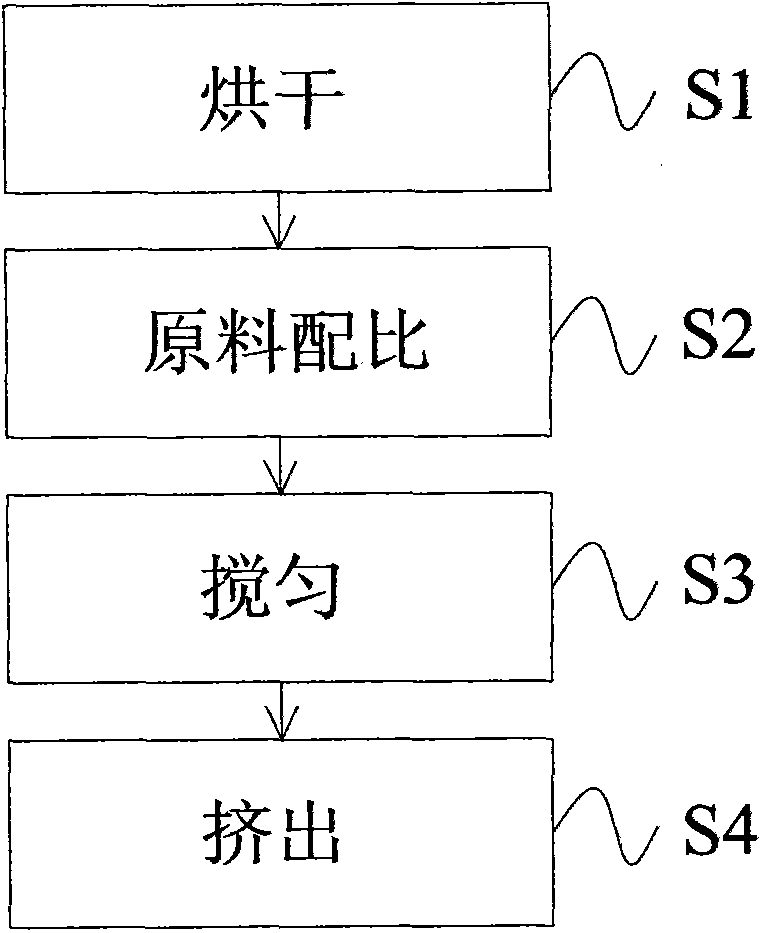

Method used

Image

Examples

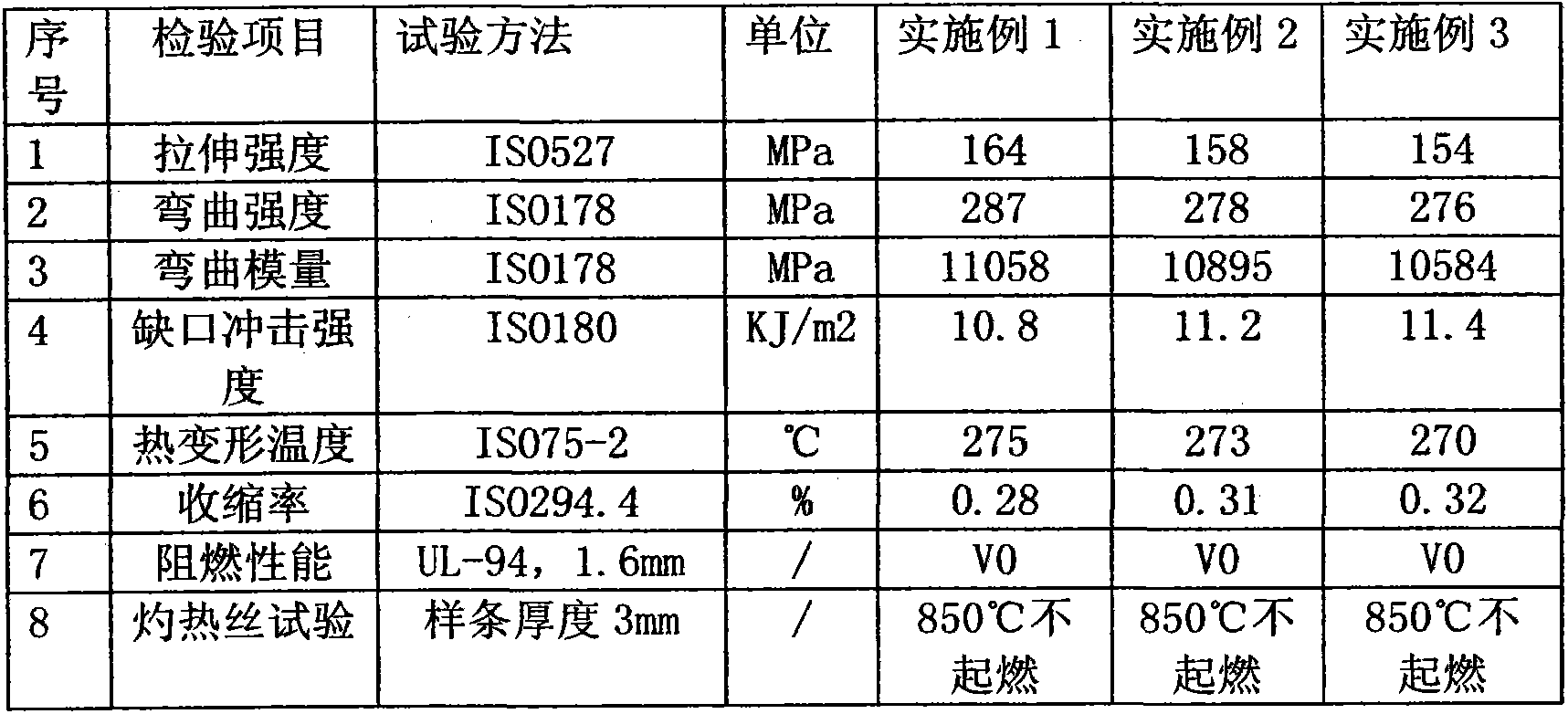

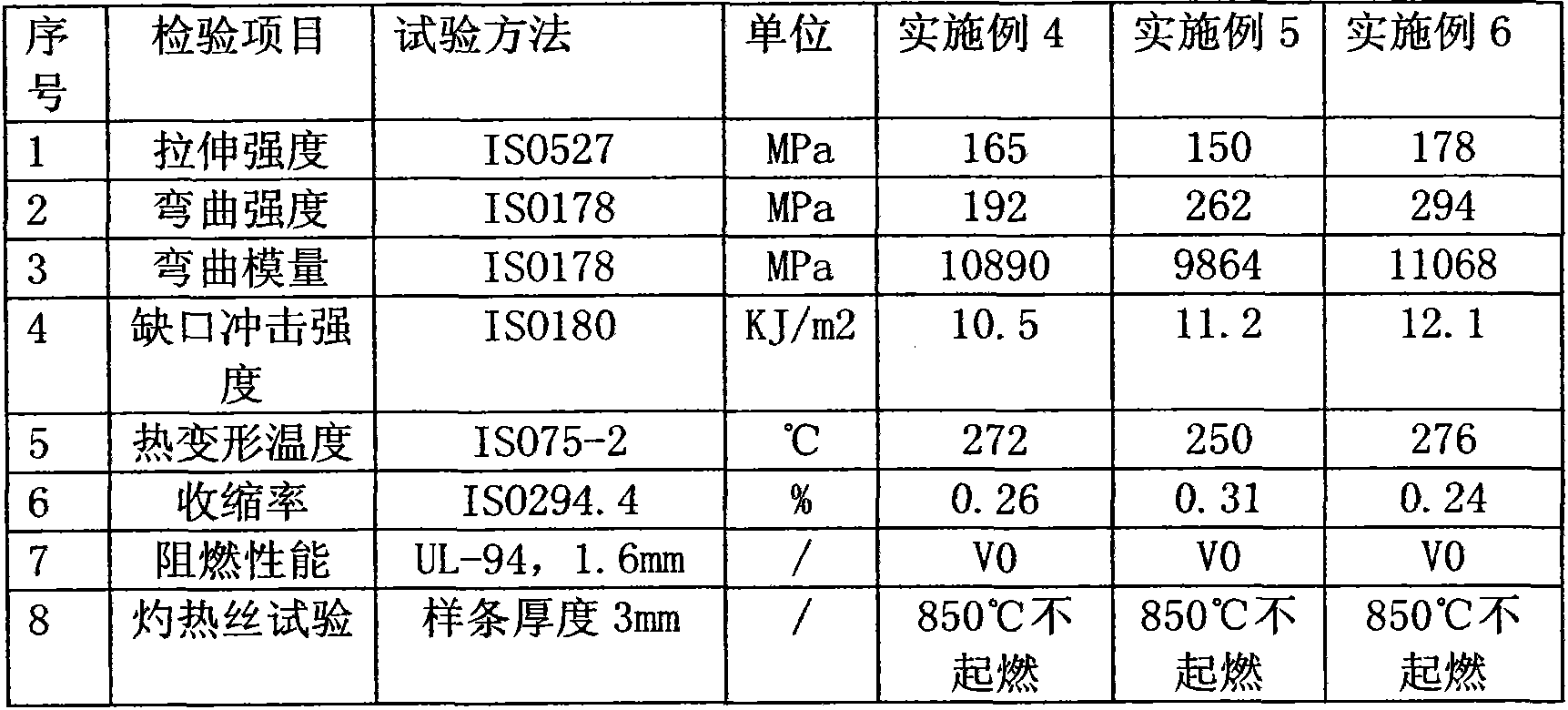

Embodiment 1

[0026] Add 5kg of dried nylon 66 resin (relative viscosity 2.5, moisture content 1‰), 44.4kg of PA46 resin, 0.2kg of antioxidant 1098, 0.2kg of antioxidant 168, 2kg of POE-g-MAH, and 0.5kg of oxidized polyethylene wax Stir evenly in the high-speed mixer on the main feeding device, add 12kg of brominated polystyrene, 8kg of organic phosphinate, 6kg of antimony trioxide, and 1.5kg of zinc oxide into the high-speed mixer on the 1# side feeding device Stir well in the middle, add the well-stirred mixture into the main feeder and 1# side feeder of the twin-screw extruder, and add 25kg short glass fibers into the 2# side feeder of the twin-screw extruder , granulated by a twin-screw extruder, the speed of the host is 600-800r / min, the vacuum pressure is controlled at 0.06-0.08Mpa, the speed of the host is 600-800r / min, and the vacuum pressure is controlled at 0.06-0.08MPa.

Embodiment 2

[0028] First dry 8kg of nylon 66 resin (relative viscosity 2.5, moisture content 1‰)), 44.4kg of PA46 resin, 0.2kg of antioxidant 1010, 0.2kg of antioxidant 168, 2kg of EPDM-g-MAH, 0.5kg of ethylene dihard Add fatty acid amide to the high-speed mixer on the main feeding device and stir evenly, add 12kg brominated polystyrene, 8kg tricresyl phosphate, 3kg antimony trioxide, and 1.5kg zinc oxide to the 1# side feeding device Stir well in a high-speed mixer, add the well-stirred mixture to the main feeder and 1# side feeder of the twin-screw extruder, and add 25kg of short glass fibers to the 2# side feeder of the twin-screw extruder In the device, it is granulated by a twin-screw extruder, the speed of the main machine is 600-800r / min, and the vacuum pressure is controlled at 0.06-0.08MPa. Example 3:

Embodiment 3

[0029] First, 10kg of dried nylon 66 resin (relative viscosity 2.5, moisture content 1‰)), 42.4kg PA46 resin, 0.2kg antioxidant 1098, 0.2kg antioxidant 168, 2kgSEBSM-g-MAH, 0.5kg montan wax were added to In the high-speed mixer on the main feeding device, add 12kg of decabromodiphenylethane, 8kg of organic phosphinate, 3kg of antimony trioxide, and 1.5kg of manganese oxide into the high-speed mixer on the 1# side feeding device, Stir evenly and add to the main feeder and 1# side feeder of the twin-screw extruder, add 25kg short glass fibers to the 2# side feeder of the twin-screw extruder, and extrude through the twin-screw extruder Machine granulation, the host speed is 600-800r / min, and the vacuum pressure is controlled at 0.06-0.08MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com