Nanometer photo-catalyst used in producing hydrogen by decomposing water under visible light response and application of nanometer photo-catalyst

A nano-photocatalyst and visible light technology, which is applied in the field of solar photocatalytic hydrogen production, can solve the problems of low energy consumption for environmental protection, poor sunlight utilization, and low efficiency of sensitizers, so as to save costs, realize recycling, and have good product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

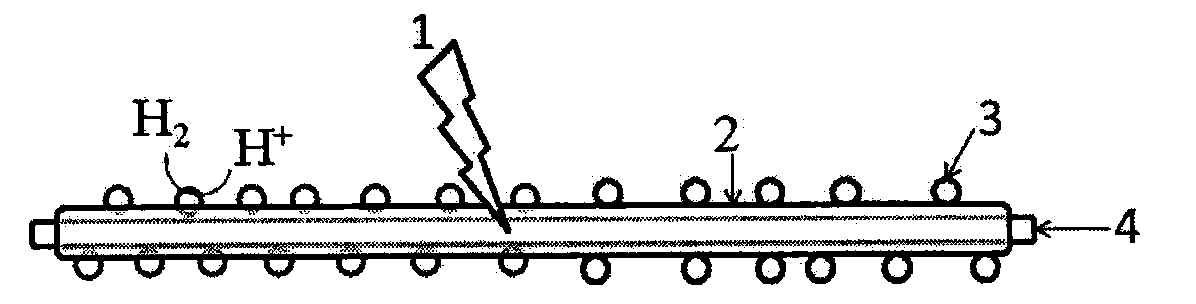

[0036] Select N-dodecyl-N'-dimethylamino-p-benzyl-perylenediimide as the π-conjugated organic molecule, where dimethylamino-p-benzyl is the electron donor Group, with chloroform as a good solvent and methanol as a poor solvent, the specific steps are as follows:

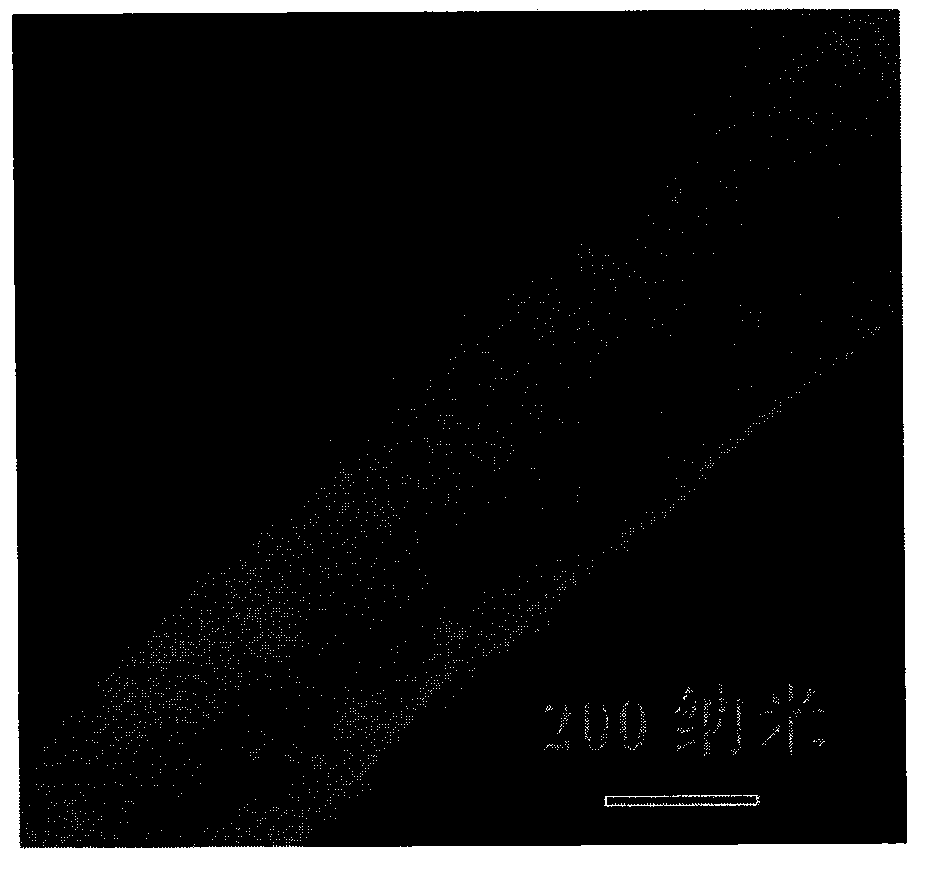

[0037] Preparation of one-dimensional nanofiber 4 as a skeleton:

[0038] Slowly inject 500 ml of methanol into a beaker containing 100 ml of chloroform solution containing 0.025 g of N-dodecyl-N'-dimethylamino-p-benzyl-perylene diimide, and seal it with a The membrane was sealed and left to stand for 24 hours at a constant temperature of 20°C to finally obtain a stable dispersion of N-dodecyl-N'-dimethylamino-p-benzyl-perylenediimide nanofibers, Wherein used chloroform and methyl alcohol are the anhydrous solvents that adopt solvent distillation device to refine;

[0039] Surface coated titanium dioxide inorganic semiconductor nano-layer 2:

[0040] Under nitrogen protection and magnetic stirring, in the chlorofo...

Embodiment 2

[0044] Select N-dodecyl-N'-dimethylamino-p-phenyl-perylene diimide as the π-conjugated organic molecule, where dimethylamino-p-phenyl is the electron donor Group, take chloroform as a good solvent and methanol as a poor solvent, and the specific operation steps are carried out according to Example 1:

[0045] Preparation of one-dimensional nanofiber 4 as a skeleton:

[0046] Slowly inject 500 ml of methanol into a beaker containing 100 ml of chloroform solution containing 0.025 g of N-dodecyl-N'-dimethylamino-p-phenyl-perylene diimide, and seal it with a The membrane was sealed and left to stand for 24 hours at a constant temperature of 20°C to finally obtain a stable dispersion of N-dodecyl-N'-dimethylamino-p-phenyl-perylenediimide nanofibers, Wherein used chloroform and methyl alcohol are the anhydrous solvents that adopt solvent distillation device to refine;

[0047] Surface coated titanium dioxide inorganic semiconductor nano-layer 2:

[0048] Under nitrogen protection...

Embodiment 3

[0052] Choose N-dodecyl-N'-pyridyl-p-phenyl-perylene diimide as the π-conjugated organic molecule, where pyridyl-p-phenyl is the electron-donating group, and trichloro Methane is a good solvent and methanol is a poor solvent, and the specific operation steps are carried out according to Example 1:

[0053] Preparation of one-dimensional nanofiber 4 as a skeleton:

[0054] Slowly inject 500 ml of methanol into a beaker containing 100 ml of chloroform containing 0.025 g of N-dodecyl-N'-pyridyl-p-phenyl-perylenediimide, seal it with parafilm and Standing for 24 hours in a constant temperature environment of 20°C, the dispersion of stable N-dodecyl-N'-pyridyl-p-phenyl-perylenediimide nanofibers was finally obtained, in which chloroform and Methanol is an anhydrous solvent refined by a solvent distillation device;

[0055] Surface coated titanium dioxide inorganic semiconductor nano-layer 2:

[0056] Under nitrogen protection and magnetic stirring, in the chloroform / methanol dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com