Coated controlled-release fertilizer and preparation method thereof

A technology of coated controlled-release fertilizer and coating layer, which is applied in the chemical field and can solve problems such as poor uniformity of polyurethane, difficulty in controlling the reaction rate and degree between raw materials, and affecting the controlled-release performance of the film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

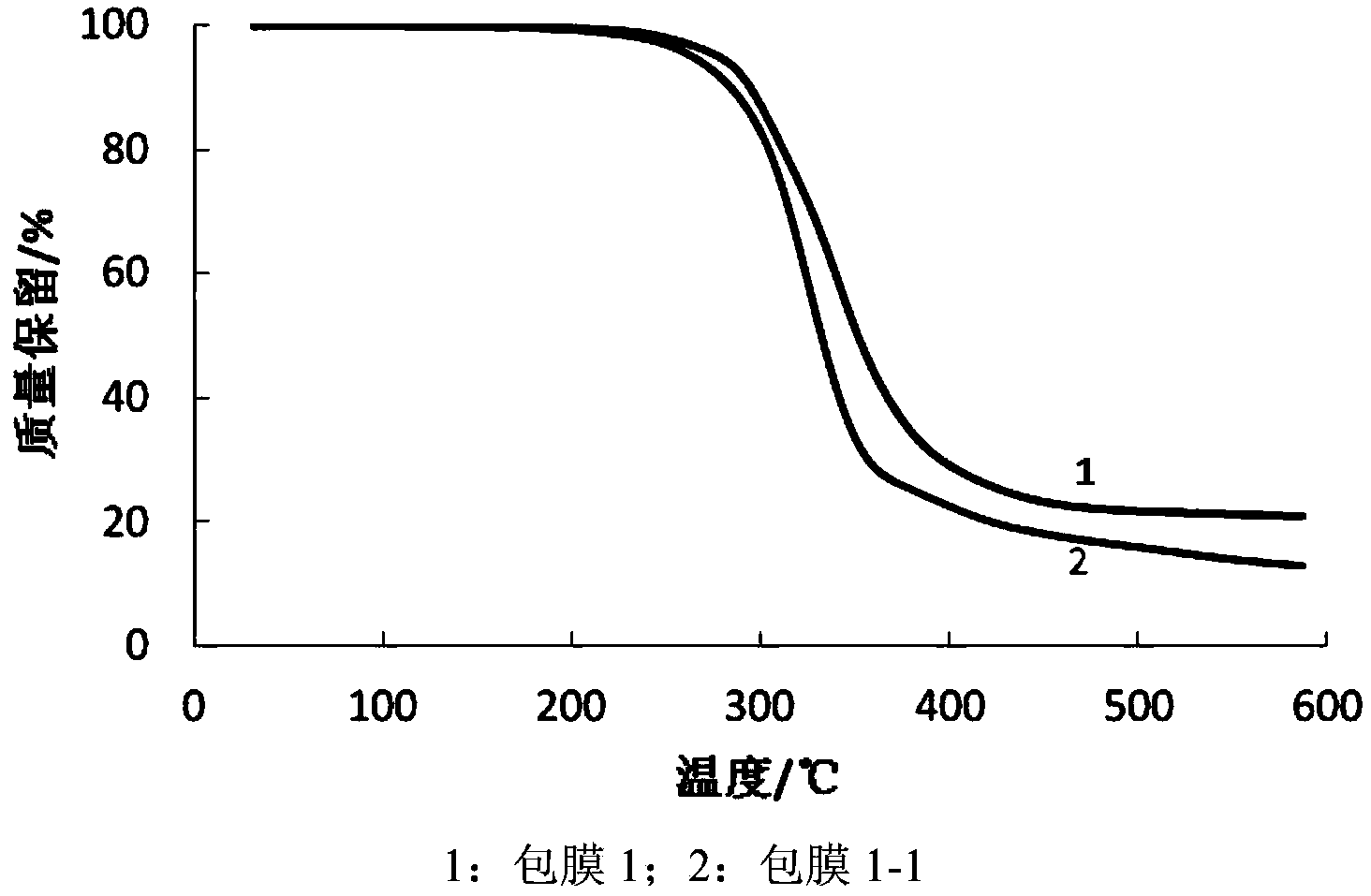

Image

Examples

Embodiment 1

[0059] Weigh 1 kg of urea granules, place in a fluidized bed, and preheat to 85°C;

[0060] Add 0.96g of dried mesoporous molecular sieve SBA-15 with a pore structure with an average particle size of 1 μm (purchased from Nanjing Xianfeng Nano Material Technology Co., Ltd.) Be SKR-T5, relative molecular mass is 500), 0.024g catalyst dibutyltin dilaurate and 0.24g dewatering agent p-toluenesulfonyl isocyanate (purchased from German Bayer company, trade mark is Additive T1) in the heating kettle, The melting temperature is kept at 95°C, and the mesoporous molecular sieve is uniformly dispersed under the strong action of mechanical stirring to obtain A1 material;

[0061] Weigh 1.2g film-forming agent paraffin and 0.15g leveling agent organosilicon D4 (octamethylcyclotetrasiloxane, purchased from Dow Corning) and place in a heating kettle, and according to the molar ratio of [NCO] and [OH] Add 16g of MDI (purchased from Yantai Wanhua Polyurethane Co., Ltd.) at a ratio of 1.07:1, ...

Embodiment 2

[0071] Weigh 1 kg of urea granules, place in a drum, and preheat to 75°C;

[0072] Add 0.56g of dried mesoporous molecular sieve SBA-15 powder with an average particle size of 1 μm into a mixture containing 24g of polytetrahydrofuran diol (purchased from BASF, Germany, the brand is PolyTHF1000, and the relative molecular mass is 1000) and 0.018g organotin catalyst (dibutyltin diacetate: dibutyltin dilaurate mass ratio: 1:9) was melted in a heating kettle at a constant temperature of 90°C, and the mesoporous molecular sieve was evenly dispersed under the strong action of mechanical stirring , get A3 materials;

[0073] Weigh 2.2g film-forming agent microcrystalline wax, and add 18g liquefied MDI (purchased from Yantai Wanhua, model PMM-10) according to the molar ratio of [NCO] to [OH] of 1.21:1, and place it under heating Stir evenly in the kettle and melt at a constant temperature to 90°C to obtain material B3;

[0074] A3 material and B3 material are atomized and sprayed on...

Embodiment 3

[0078] Weigh 1kg of Sacofu compound fertilizer (N-P-K: 15-15-15), place it in a drum, and preheat it to 90°C;

[0079] Add 1.59g of dried mesoporous molecular sieve SBA-3 former powder with an average particle diameter of 500nm into 15g of polyethertriol and 20g of polyetherdiol (purchased from Jiangsu Zhongshan Chemical Industry Co., Ltd., the brands are N330 and N220, the relative molecular mass is respectively 3000 and 2000) and 0.012g catalyst stannous octoate heating kettle, melting constant temperature to 90 ℃, and make the mesoporous molecular sieve disperse evenly under the ultrasonic action, obtain A4 material;

[0080] Weigh 1.6g film-forming agent microcrystalline wax and 0.03g leveling agent silicone (purchased from German BYK Chemicals, brand name BYK-LPG7018), and according to the molar ratio of [NCO] to [OH] is 1.19:1 Proportionally add 15.7g polymethylene polyphenyl polyisocyanate (purchased from Bayer, Germany, brand name Desmodur44V20L), put it in a heating k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com