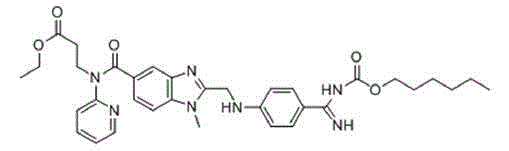

Dabigatran etexilate preparation method

A technology for dabigatran etexilate and an intermediate, which is applied in the field of preparing dabigatran etexilate, can solve the problems of difficult purification and purification of compounds, and is unfavorable for large-scale production, and achieves cheap raw materials, simple and easy-to-control operations, and reaction yields. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing dabigatran etexilate (7), comprising the following steps:

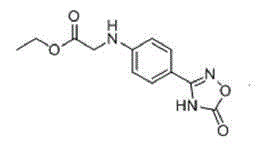

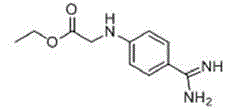

[0031] (a) Preparation of intermediate 1: Add 40g p-aminobenzonitrile, 93.8g potassium carbonate and 150mL water to 600mL tetrahydrofuran, stir, add dropwise 200mL aqueous solution of hydroxylamine hydrochloride; after dropping, heat up to 50°C for reaction, TLC Monitor the reaction; after the reaction is completed, cool down to room temperature naturally, evaporate THF under reduced pressure, cool, filter with suction, wash the filter cake with ether, and dry to obtain 52.8 g of Intermediate 1 (1) with a purity of 98.5% and a yield of 88%. ;

[0032] (b) Preparation of Intermediate 2: In 400mL of anhydrous methanol, add 13.7g of sodium methoxide, stir to dissolve, add 30g of Intermediate 1 (1), stir, add 22.5g of diethyl carbonate dropwise, dropwise, heat up to React at 55-60°C, monitor the reaction by TLC; after the reaction is complete, concentrate under reduced pressure to remove met...

Embodiment 2

[0039] A method for preparing dabigatran etexilate (7), comprising the following steps:

[0040] (a) Preparation of intermediate 1: Add 32g p-aminobenzonitrile, 69.7g DIPEA and 100mL water to 500mL tetrahydrofuran, stir, add dropwise 100mL aqueous solution of hydroxylamine hydrochloride; after dropping, raise the temperature to 50°C for reaction, monitor by TLC Reaction: After the reaction was completed, the temperature was naturally lowered to room temperature, the tetrahydrofuran was evaporated under reduced pressure, cooled, filtered with suction, the filter cake was washed with ether, and dried to obtain 41.8 g of intermediate 1 (1) with a purity of 97.4% and a yield of 87%;

[0041](b) Preparation of Intermediate 2: Add 23g of sodium ethoxide to 500mL of absolute ethanol, stir to dissolve, add 40g of Intermediate 1 (1), stir, add 30.4g of diethyl carbonate dropwise, and heat up to 75-80°C reaction, TLC monitors the reaction; after the reaction is completed, concentrate un...

Embodiment 3

[0048] A method for preparing dabigatran etexilate (7), comprising the following steps:

[0049] (a) Preparation of intermediate 1: In 800mL of acetonitrile, add 48g of p-aminobenzonitrile, 67.2g of sodium carbonate and 200mL of water, stir, and add dropwise 200mL of hydroxylamine hydrochloride aqueous solution; after dropping, heat up to 50°C for reaction, TLC Monitor the reaction; after the reaction is completed, cool down to room temperature naturally, evaporate THF under reduced pressure, cool, filter with suction, wash the filter cake with ether, and dry to obtain 63.4 g of Intermediate 1 (1) with a purity of 97.9% and a yield of 88%. ;

[0050] (b) Preparation of Intermediate 2: In 700mL of anhydrous methanol, add 24.7g of sodium methoxide, stir to dissolve, add 54g of Intermediate 1 (1), stir, add 40.5g of diethyl carbonate dropwise, drop the temperature to React at 55-60°C, monitor the reaction by TLC; after the reaction is complete, concentrate under reduced pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com