A method for microbial fermentation and purification of tea saponin

A technology of microbial fermentation and tea saponin, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of high safety production requirements, high methanol toxicity, and large usage, so as to shorten the production cycle, Low production cost and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

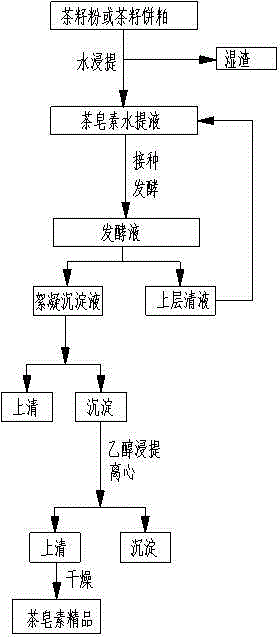

Image

Examples

Embodiment 1

[0020] Example 1: Pulverize the tea seed cake, pass through an 80-mesh sieve, weigh 150g of the pulverized tea seed powder, add it to 1500mL of 40°C water for ultrasonic extraction for 40 minutes, centrifuge to remove the precipitate, and prepare the supernatant for inoculation 50mL of good microbial fermentation yeast liquid, covered with gauze, let stand for 3 days, centrifuged to get the flocculation sediment, leached the sediment with 80% ethanol solution, centrifuged, the supernatant was evacuated and rotary evaporated, and the concentrated solution was sprayed After drying, the purity of tea saponin was measured to be (80%).

Embodiment 2

[0021] Example 2: Extract the pulverized Camellia oleifera seed powder with water for 40 minutes according to mass (g): volume (mL) = 1:10, filter to get the supernatant, and inoculate the prepared microbial fermentation yeast liquid with a volume ratio of 1:1 , let it stand for 2 days, take the supernatant, add fresh tea seed powder extract at a volume ratio of 1:1, and continue to ferment; such a cycle constitutes a semi-continuous fermentation. The flocs in the lower layer are centrifuged to obtain a precipitate and a supernatant, which is sterilized and then added to the rough extraction process of tea seed powder; the precipitate is leached with an ethanol solution with a mass concentration of 80%, centrifuged, and the supernatant is evacuated and rotated to evaporate. The concentrated solution was spray-dried, and the purity of tea saponin was measured to be (85%).

[0022] The microorganisms in the fermented yeast liquid used in Examples 1 and 2 are mainly microorganism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com