Preparation method and application of magnetic microsphere for biological protein separation

A magnetic microsphere and biological protein technology, applied in the field of biological protein separation, can solve the problems that the specific separation effect of biological protein needs to be further studied, and the preparation process of magnetic microspheres is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

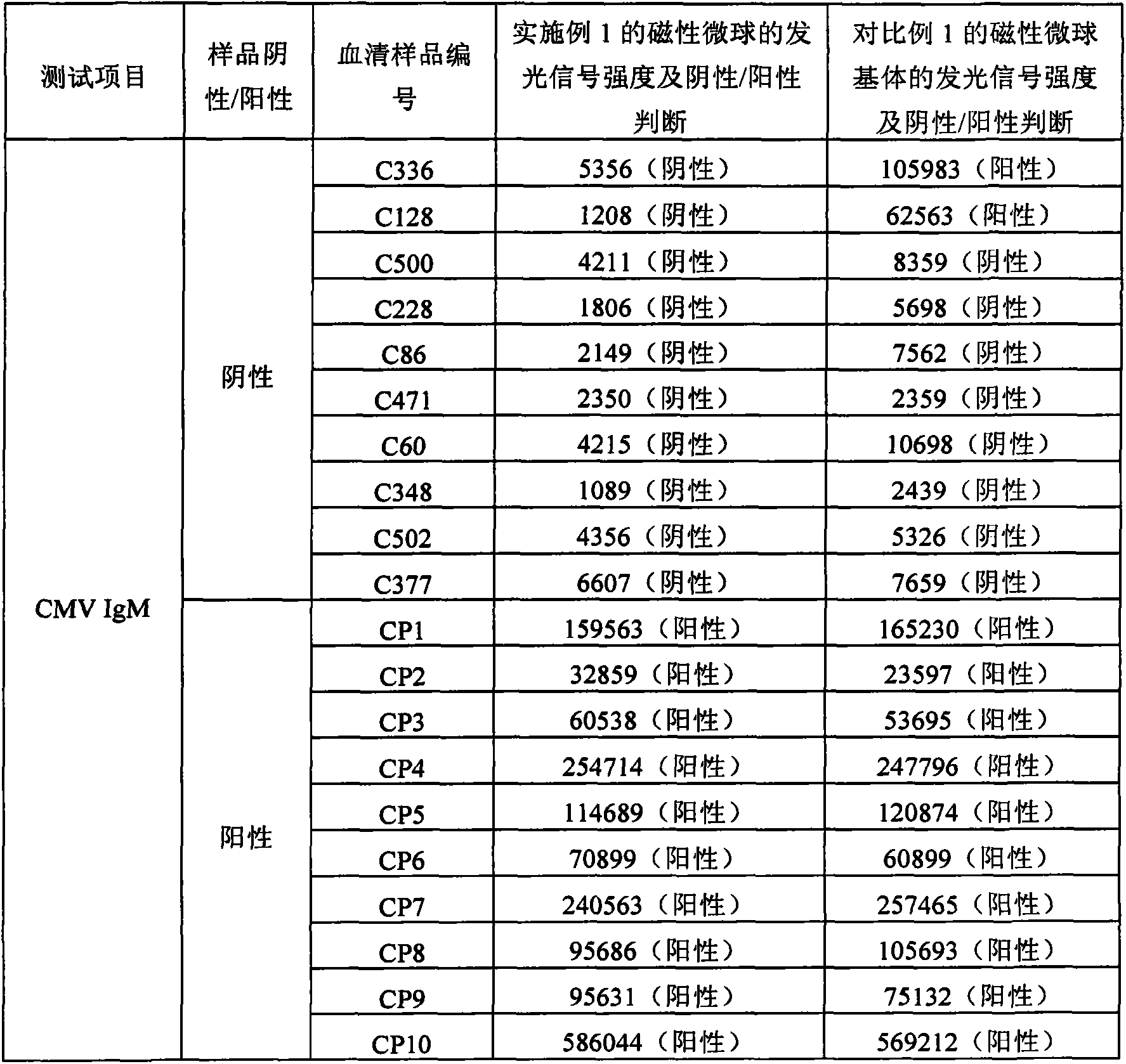

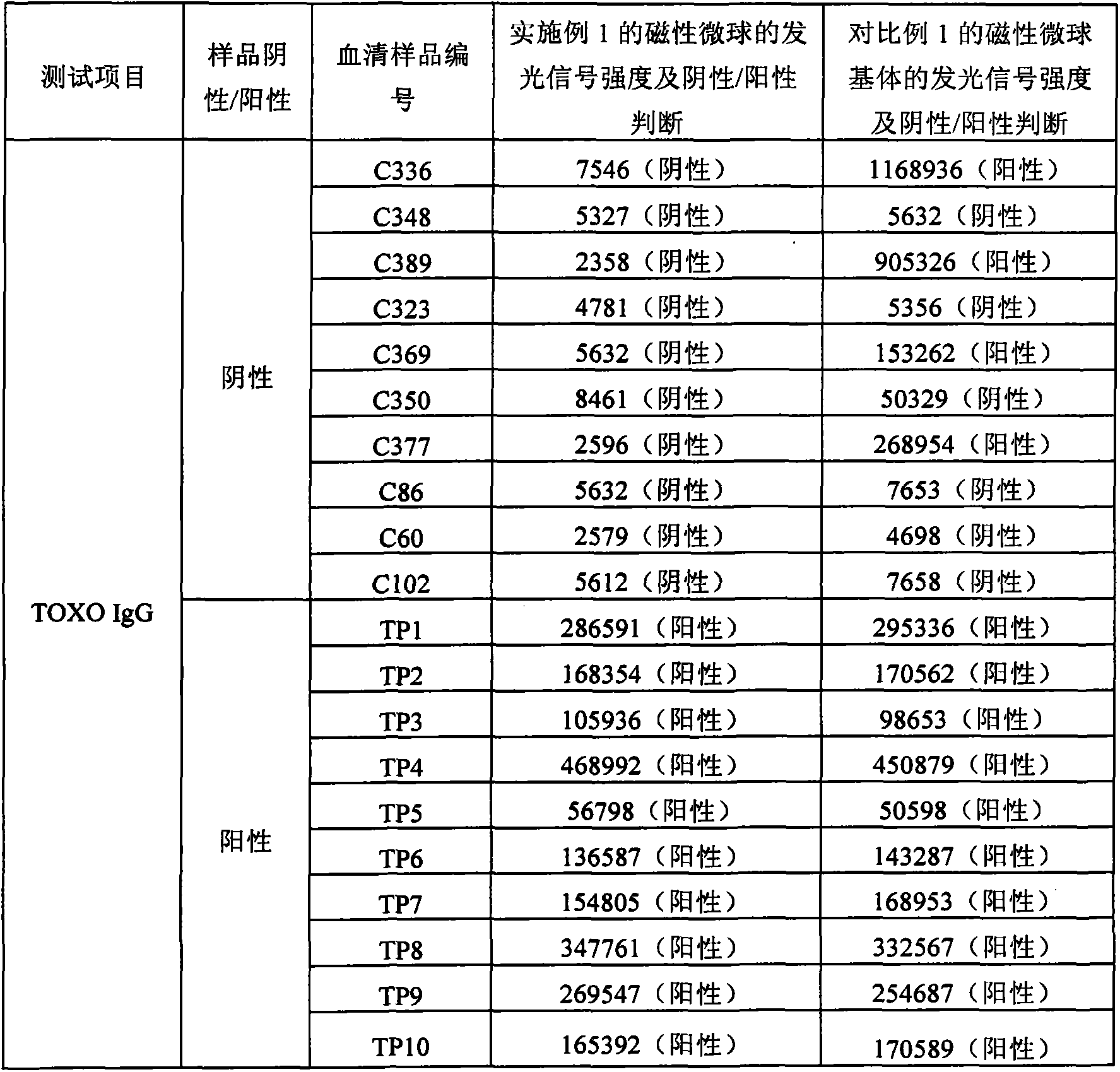

Examples

Embodiment 1

[0030] 1) Preparation of magnetic microsphere matrix

[0031] The magnetic microsphere matrix with carboxyl functional groups used in this example was prepared according to Example 1 in Chinese Patent CN92105584.

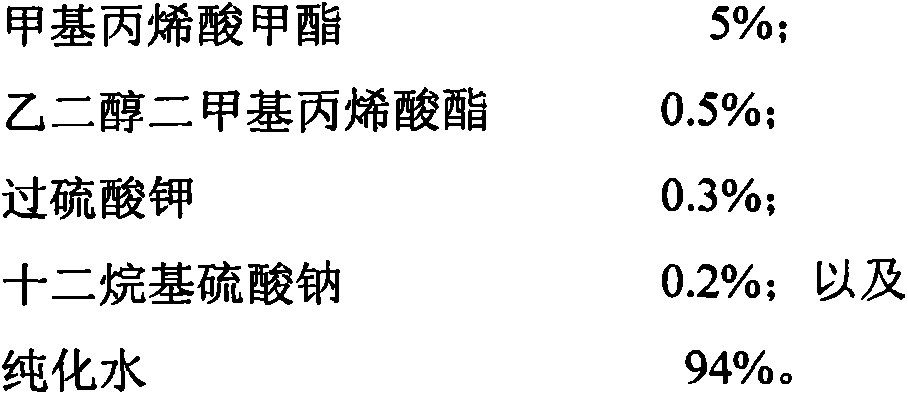

[0032] 2) Preparation of emulsion

[0033] The components of the emulsion and their mass percentages are as follows:

[0034]

[0035] The above-mentioned components are mixed in proportion, ultrasonically treated to dissolve all the solid components, and then further fully mixed.

[0036] 3) Preparation of dispersion system

[0037] The magnetic microsphere matrix obtained in step 1) is dispersed in the emulsion prepared in step 2) at a concentration of 20 mg / mL, and the magnetic microsphere matrix is uniformly dispersed by ultrasonic treatment to obtain a dispersion system.

[0038] 4) Polymerization and post-treatment

[0039] The dispersion system prepared in step 3) was stirred and reacted at 75° C. for 30 hours, the supernatant was separated by a magn...

Embodiment 2

[0067] 1) Preparation of magnetic microsphere matrix

[0068] The magnetic microsphere matrix used in this example was prepared according to Examples 1-6 in Chinese Patent Publication CN102746529A. That is, polystyrene polymer seed particles are first prepared; then the seed particles are modified with an emulsion containing polyvinylpyrrolidone, divinylbenzene, styrene and toluene (pore forming agent), and the porosity is obtained by emulsion polymerization. polystyrene particles; the porous polystyrene particles were nitrated using nitric acid; then FeSO 4 Iron was incorporated into the porous polystyrene particles; and then the resulting particles were coated and carboxyl functionalized to obtain the magnetic microsphere matrix with carboxyl functional groups used in this example.

[0069] 2) Preparation of emulsion

[0070] The components of the emulsion and their mass percentages are as follows:

[0071]

[0072] The above-mentioned components are mixed in proportio...

Embodiment 3

[0082] Experiment with reference to the steps of Example 2, the difference is only to replace the emulsion in Example 2 with the following emulsion:

[0083] The components of the emulsion and their mass percentages are as follows:

[0084]

[0085]

[0086] The results are shown in Table 5-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com