Polyacrylic acid printing ink resin and preparation method thereof

A technology of ink resin and polyacrylic acid, which is applied in the field of printing ink, can solve the problems of severe printing suitability of ink resin, achieve good solvent release, inhibit gel, and ensure controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

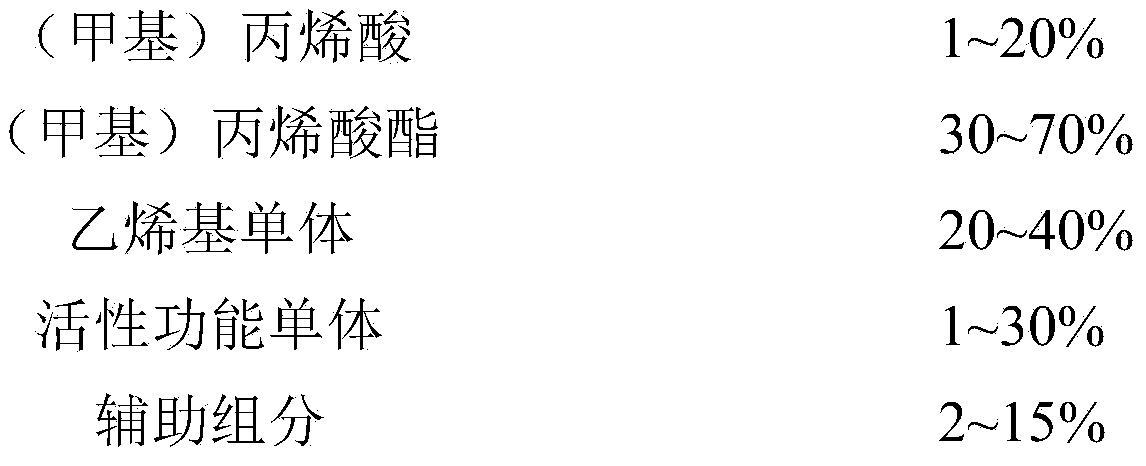

Method used

Image

Examples

Embodiment 1

[0028] 1 kg of methacrylic acid, 41 kg of methyl methacrylate, 40 kg of styrene, 1 kg of maleic acid, 15 kg of rosin, 1 kg of isopropanol, 1 kg of azobisisobutyl Nitrile is mixed evenly in the feed tank to obtain reaction materials, and then the reaction materials are pumped into a tubular reactor equipped with a static mixing device for continuous bulk polymerization; when performing continuous bulk polymerization, the temperature of the tubular reactor is 100 ℃, the pressure is 0.5MPa, and the residence time of the reaction material in the tubular reactor is 40 minutes; after the reaction product is discharged, it is extracted and granulated to obtain a polyacrylic acid ink resin with a number average molecular weight of 70,000.

Embodiment 2

[0030] 10 kg of acrylic acid, 10 kg of methacrylic acid, 12 kg of butyl acrylate, 18 kg of pentyl acrylate, 21 kg of vinyl butyrate, 9 kg of methyl styrene, 10 kg of itaconic acid, 5.5 kg of acrylonitrile, 1 kg of rosin phenolic resin, 1 kg of epoxy resin, 0.3 kg of propylene glycol, 0.2 kg of thioglycolic acid, 0.5 kg of benzoyl peroxide, 1.5 kg of dicumyl peroxide in The reaction materials are mixed uniformly in the feeding tank, and then the reaction materials are pumped into a tubular reactor equipped with a static mixing device for continuous bulk polymerization; when performing continuous bulk polymerization, the temperature of the tubular reactor is 300 °C, The pressure is 4MPa, and the residence time of the reaction material in the tubular reactor is 2 minutes; after the reaction product is discharged, it is extracted and granulated to obtain a polyacrylic acid ink resin with a number average molecular weight of 10,000.

Embodiment 3

[0032]7 kg of acrylic acid, 3.5 kg of methacrylic acid, 10 kg of isobutyl acrylate, 40 kg of nonyl methacrylate, 5 kg of vinyl laurate, 15 kg of tertiary vinyl carbonate, 5 kg of acrylic acid -2-hydroxyethyl ester, 7 kg of acrylamide, 1 kg of cellulose, 2 kg of polycarbonate, 0.1 kg of mercaptohexanol, 0.4 kg of 3-mercaptopropionic acid, 2.5 kg of diacetyl peroxide, 1.5 kg of tert-butyl peroxylaurate is mixed uniformly in the feed tank to obtain the reaction material, and then the reaction material is pumped into a tubular reactor equipped with a static mixing device for continuous bulk polymerization; , the temperature of the tubular reactor is 200°C, the pressure is 3.5MPa, and the residence time of the reaction material in the tubular reactor is 30 minutes; after the reaction product is discharged, it is extracted and granulated to obtain the number average molecular weight 50,000 polyacrylic ink resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com