A method for preparing anatase titanium dioxide nanoribbon array film

A technology of titanium dioxide and nanobelts, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high industrialization cost, poor environmental friendliness, and high equipment requirements, and achieve low equipment requirements, Low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Mix hydrofluoric acid with a mass percentage concentration of 55%, nitric acid with a mass percentage concentration of 65% and deionized water in a volume ratio of 1:3:6 to obtain a pickling solution;

[0022] 2) Add 0.0024 mol / L melamine and 0.04 mol / L tungstic acid to 50 ml of 30% hydrogen peroxide solution by mass to obtain a reaction solution;

[0023] 3) Set the size to 5×5×0.01 (cm 3 ) The surface of the metal titanium plate is pickled with pickling solution, and then cleaned with deionized water in ultrasonic waves. Immerse the cleaned metal titanium plate in 50 ml of reaction solution, at 90 o Reaction under C for 60 hours;

[0024] 4) After the reaction, the titanium plate was washed with deionized water, and dried at 450 o C heat treatment for 1 hour.

[0025] Response result

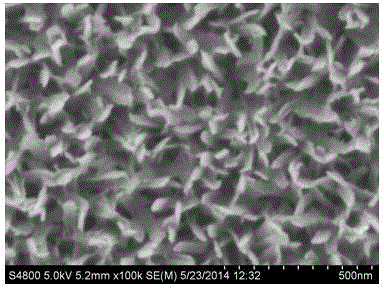

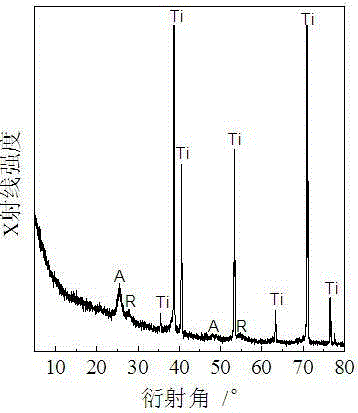

[0026] The surface of the titanium plate is uniformly generated as figure 1 In the titanium dioxide nanobelt film shown, the average width of the nanobelt is about 55 nanometer...

Embodiment 2

[0028] 1) Mix hydrofluoric acid with a mass percentage concentration of 55%, nitric acid with a mass percentage concentration of 65% and deionized water in a volume ratio of 1:3:6 to obtain a pickling solution;

[0029] 2) Add 0.0024 mol / L melamine and 0.004 mol / L tungstic acid to 50 ml of 30% hydrogen peroxide solution by mass to obtain a reaction solution;

[0030] 3) Set the size to 5×5×0.01 (cm 3 ) The surface of the metal titanium plate is pickled with pickling solution, and then cleaned with deionized water in ultrasonic waves. Immerse the cleaned metal titanium plate in 50 ml of reaction solution, at 60 o Reaction under C for 12 hours;

[0031] 4) After the reaction, the titanium plate was washed with deionized water, and dried at 450 o C heat treatment for 1 hour.

[0032] Response result

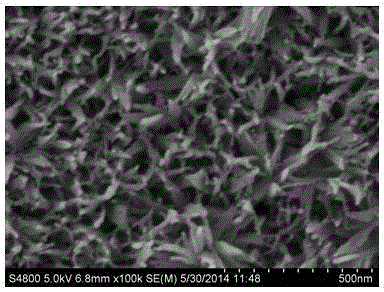

[0033] The surface of the titanium plate is uniformly generated as image 3 In the titanium dioxide nanoribbon film shown, the average width of the nanoribbon is about 35 nano...

Embodiment 3

[0035] 1) Mix hydrofluoric acid with a mass percentage concentration of 55%, nitric acid with a mass percentage concentration of 65% and deionized water in a volume ratio of 1:3:6 to obtain a pickling solution;

[0036] 2) Add 0.0024 mol / L melamine and 0.008 mol / L tungstic acid to 50 ml of 30% hydrogen peroxide solution by mass to obtain a reaction solution;

[0037] 3) Set the size to 5×5×0.01 (cm 3 ) The surface of the metal titanium plate is pickled with pickling solution, and then cleaned with deionized water in ultrasonic waves. Immerse the cleaned metal titanium plate in 50 ml of reaction solution, at 85 o Reaction under C for 48 hours;

[0038] 4) After the reaction, the titanium plate was washed with deionized water, and dried at 450 o C heat treatment for 1 hour.

[0039] Response result

[0040] The surface of the titanium plate is uniformly generated as Figure 4 In the titanium dioxide nanoribbon film shown, the average diameter of the nanoribbon is about 58 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com