A nano-filler capillary chromatography micro-column preparation device and preparation method thereof

A technology of capillary chromatography and nanofiller, which is applied in the field of nanofiller capillary chromatography microcolumn preparation device and its preparation, can solve the problems of long preparation cycle, complicated preparation process of nanofiller capillary chromatography microcolumn, expensive equipment required for preparation, etc., to achieve The method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

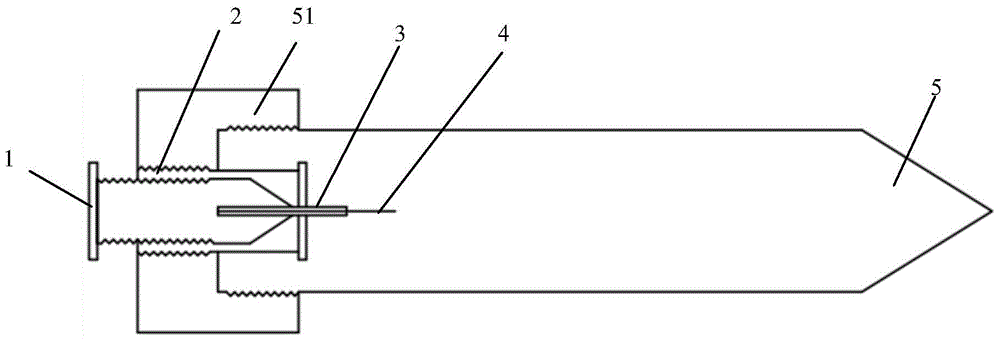

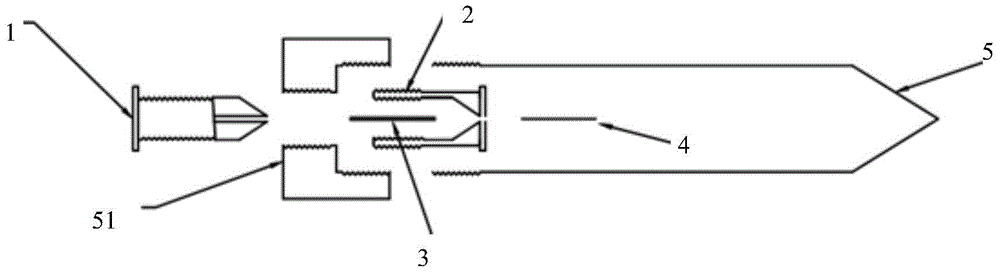

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Alkyl modified SiO 2 Preparation of Nano-filled Capillary Chromatography Microcolumns

[0035] a Alkyl modified SiO 2 Synthesis of nanofillers

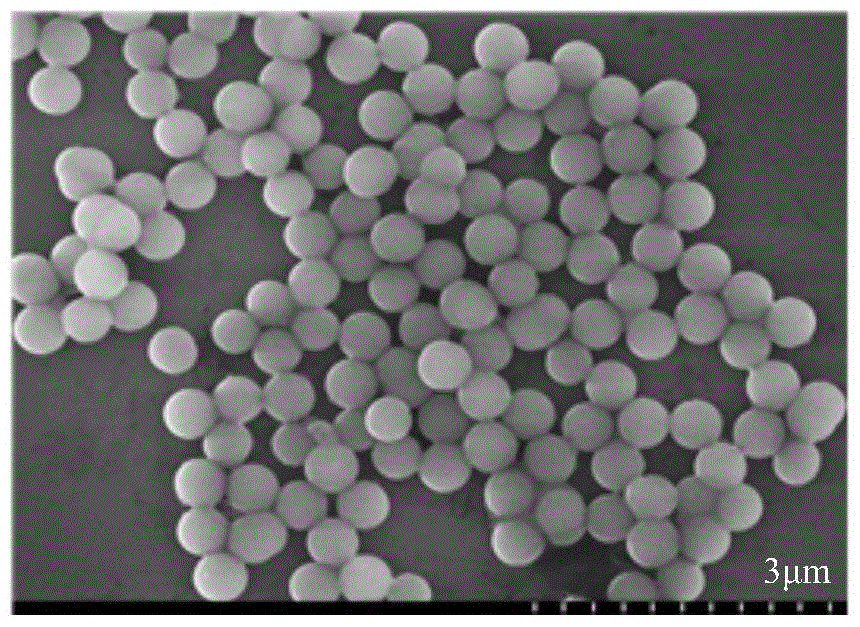

[0036] Mix absolute ethanol, water and ammonia water in a volume ratio of 47:9:14 into a round-bottomed flask, magnetically stir and mix evenly, and add the above 1 / 14 volume tetraethyl orthosilicate while stirring. Closed and stirred at a certain temperature for 6-10 hours; then add half volume of tetraethyl orthosilicate, absolute ethanol, water, etc. under stirring state, continue to react for 6-10 hours, age for 1-2 hours, centrifuge and wash for at least 3 times, washed with ethanol at least 3 times, dried at 110°C for 4-6 hours, and within 16 hours after cooling, the temperature was programmed from room temperature to 600-650°C in a muffle furnace. image 3 and 4 For the synthesized SiO 2 Scanning electron microscope (SEM) and transmission electron microscope (TEM) images of nano fillers show that the synt...

Embodiment 2

[0048] Example 2: SiO 2 Preparation of Au-S-C18 nano-packed column for capillary chromatography enrichment

[0049] aSiO 2 Preparation of Au-S-C18 Core-Shell Nanofillers

[0050] First, a certain amount of SiO prepared according to Example 1 2 Disperse the nanospheres in 10mL of 1:1 methanol and water solution, prepare 90mL of 0.03M SnCl 2 The solution was mixed with the above nanoparticle dispersion, reacted for 45min under magnetic stirring, and dispersed in 4mL water after being washed by centrifugation for 8 times; secondly, 1.5mL1g / 100mL chloroauric acid was added to the 2 CO 3 100mL of water, react in dark for at least 24h to form aging solution. Add 1mL SiO to 50mL aging solution 2 sn 2+ For dispersion liquid, add hydroxylamine hydrochloride solution of appropriate concentration drop by drop under magnetic stirring until the reaction solution is bright blue, react for 8-10 hours, then age for 1 hour, wash with water at least 6 times, and then dry overnight at 50-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com