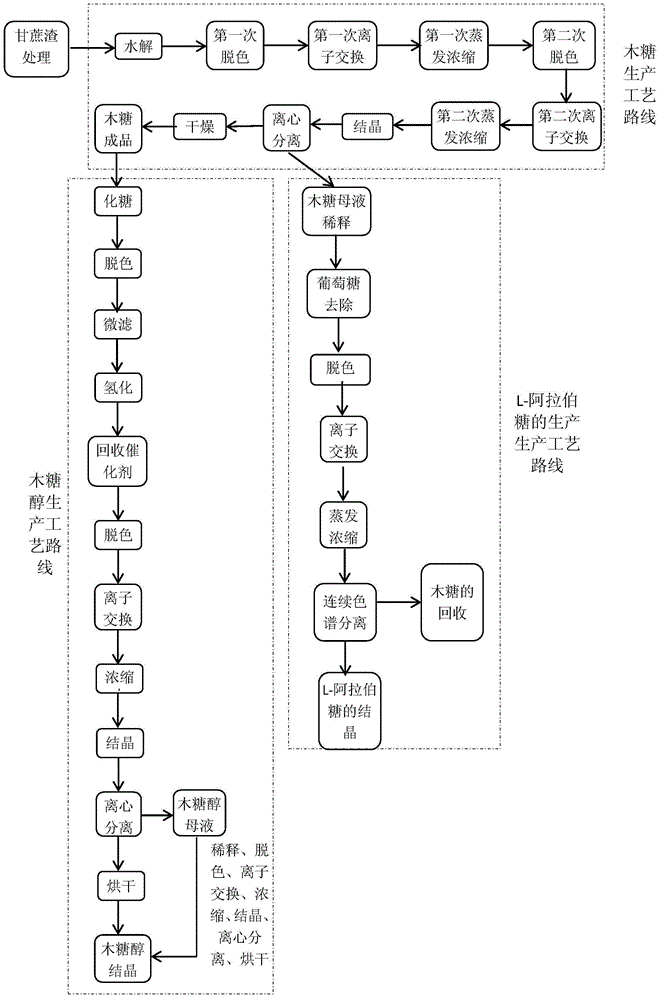

A method for bagasse to produce xylose and xylitol to co-produce l-arabinose

A technology for arabinose and bagasse, applied in the field of production of xylitol and L-arabinose, can solve the problems of poor yield of production process, low efficiency of continuous hydrogenation of xylose and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (1) Production of xylose:

[0085]Treat the bagasse with a pitting machine, the pitting rate is about 20%, the stacking time is more than 3 months, the sucrose in the bagasse has been fully fermented, and the bagasse with a yellowish-brown appearance and a moisture content of ≤15% is obtained. Safe stacking and storage work, strictly prevent the erosion of dust and rain. Drop into absolutely dry bagasse 24Kg in the hydrolysis equipment [record air-dried bagasse moisture and be 12.5%. Absolutely dry bagasse refers to bagasse that does not contain moisture at all, which is relative to air-dried bagasse; for example, if 20 tons of bagasse with a moisture content of 20%, the weight of absolute dry bagasse is 20× (1-20%) =16 tons], add 192Kg of dilute sulfuric acid solution with a mass concentration of 1.2% according to the absolute dry solid-liquid ratio (i.e. absolute dry bagasse to liquid mass ratio) 1:8, hydrolyze at 123°C and 0.12MPa for 2.5 hours, after the hydrolysis...

Embodiment 2

[0091] (1) Production of xylose:

[0092]Treat the bagasse with a pitting machine, the pitting rate is about 20%, the stacking time is more than 3 months, the sucrose in the bagasse has been fully fermented, and the bagasse with a yellowish-brown appearance and a moisture content of ≤15% is obtained. Safe stacking and storage work, strictly prevent the erosion of dust and rain. Put 24Kg of absolute dry bagasse into the hydrolysis equipment (measured air-dried bagasse moisture is 12.46%), add 192Kg of dilute sulfuric acid solution with a mass concentration of 1.2% according to the absolute dry solid-to-liquid ratio of 1:8, and hydrolyze at 123°C and 0.12MPa After 2.5 hours, after the hydrolysis is completed, the slag-liquid mixture is separated with a three-legged centrifuge, and the centrifugate is collected. After solid-liquid separation, add 60Kg of pure water to rinse the wet slag according to the absolute dry solid-to-liquid ratio of 1:2.5. The rinse solution is mixed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com