Method for improving liquid metal corrosion resistance of martensitic heat-resistant steel

A liquid metal and heat-resistant steel technology, applied in the field of laser cladding treatment and coating metal surface, can solve the problems of complex aluminum compounds, deterioration of metal mechanical properties, and high aluminum activity, to improve corrosion resistance, increase Liquid metal corrosion resistance and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Pretreatment of the metal surface: the metal sample with a size of 15mm×10mm×2mm was polished step by step to No. 800 with metallographic sandpaper, and all the edges and corners were rounded, and the surface was wetted with 200 mesh glass pellets. Sand blasting, cleaning with metal detergent, ultrasonic cleaning in deionized water, and drying.

[0026] (2) The aluminum layer is preset on the metal surface by arc ion plating, and the purity of the aluminum target is above 99%. The process conditions of arc ion plating: the vacuum degree of the vacuum chamber is 9.5×10 -3 Pa, the protective gas pressure is kept at 2Pa, the furnace chamber temperature is 130°C, the bias voltage is -800V, the arc current is 55A, the pre-sputter cleaning is 3min, and other parameters are kept unchanged, the bias voltage is adjusted to -225V, on the metal substrate Depositing an aluminum layer with a thickness of 8 μm;

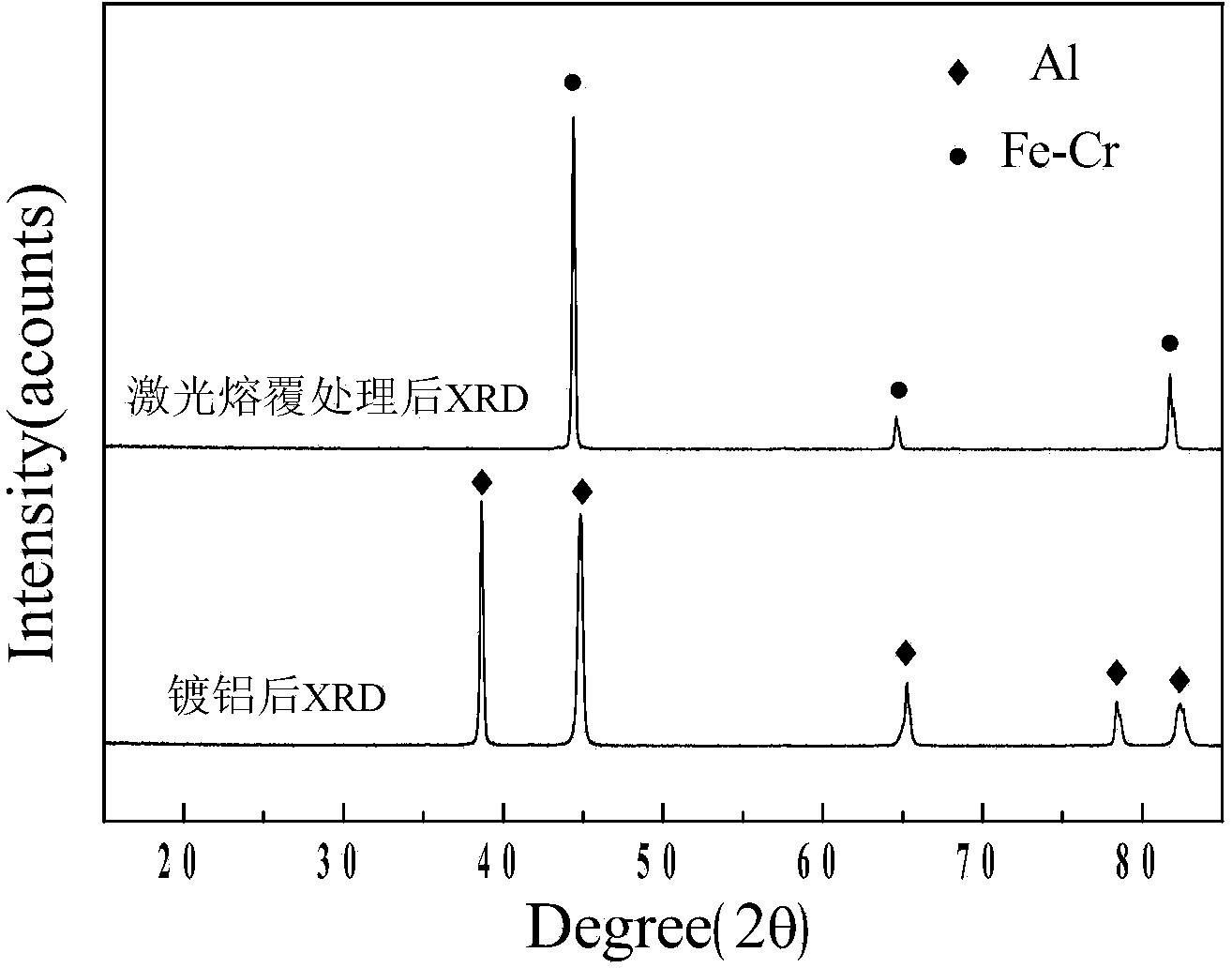

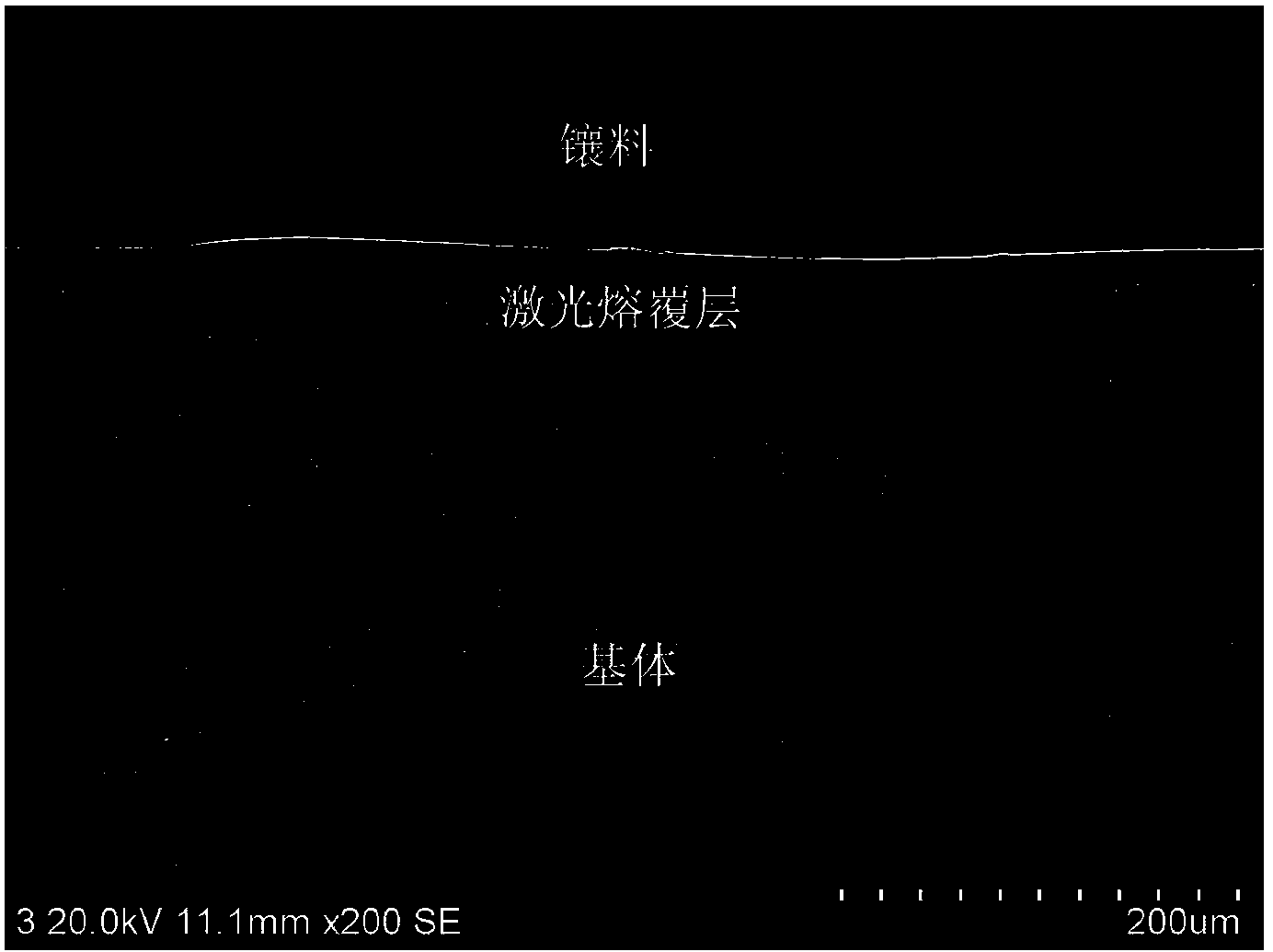

[0027] (3) Laser cladding process: use the energy of the laser bea...

Embodiment 2

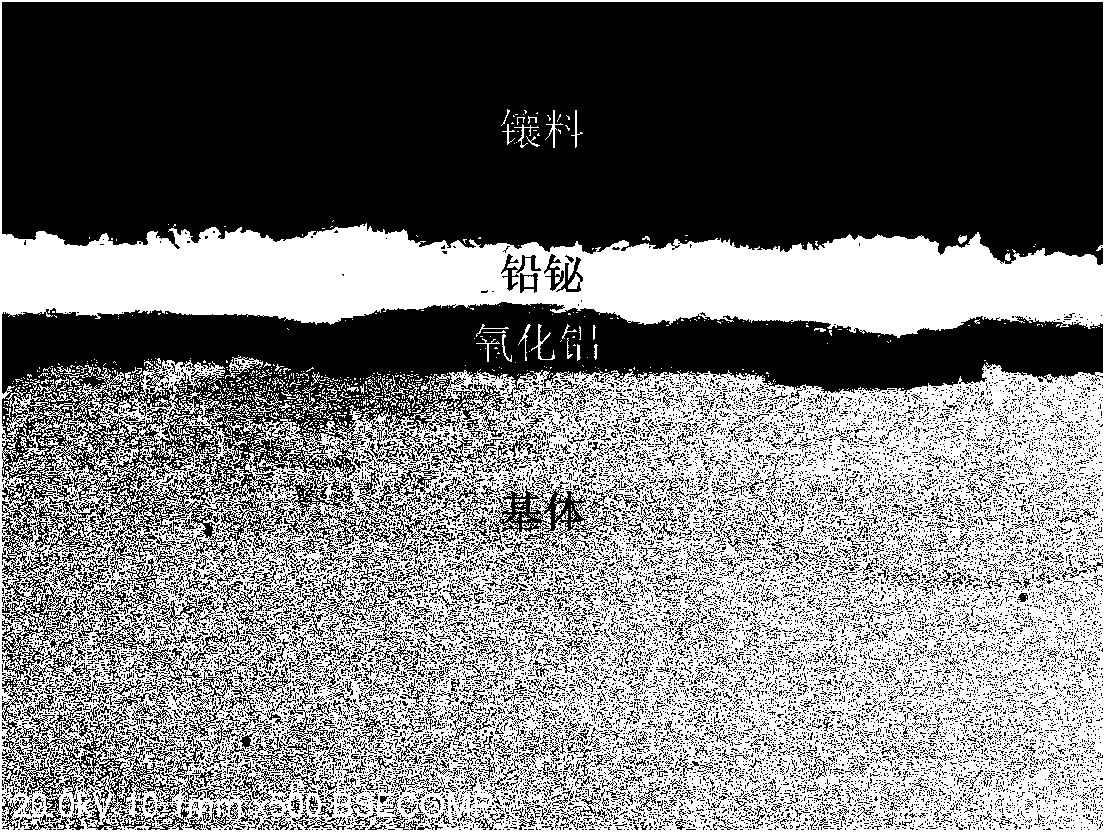

[0032] The chemical composition of 9-12% Cr martensitic heat-resistant steel is: C: 0.1wt.%, Cr: 9.04wt.%, Si: 0.26wt.%, Mn: 0.46wt.%, Mo: 0.92wt.%. , Ni: 0.17wt.%, V: 0.2wt.%, Nb: 0.04wt.%, and the balance is iron. The surface treatment process of the metal is the same as in Example 1. After corroding in the liquid lead-bismuth eutectic at 600°C for 500 hours, the cross-sectional morphology is not much different from that of Example 1, and its mechanical properties are basically unchanged.

Embodiment 3

[0034] The chemical composition of 9-12% Cr martensitic heat-resistant steel is: C: 0.22wt.%, Cr: 10.73wt.%, Si: 1.56wt.%, Mn: 0.67wt.%, W: 1.41wt.%. , Ta: 0.19wt.%, V: 0.21wt.%, Nb: 0.01wt.%, and the balance is iron. The surface treatment process of the metal is the same as in Example 1. After corroding in the liquid lead-bismuth eutectic at 600°C for 500 hours, the cross-sectional morphology is not much different from that of Example 1, and its mechanical properties are basically unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com