Haze-proof nano window screen manufacturing method

A production method and anti-smog technology, which is applied in the field of window screens, can solve the problems that window screens cannot effectively block the intrusion of fine particles into the room, and achieve the effects of large specific surface area, good filterability, and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

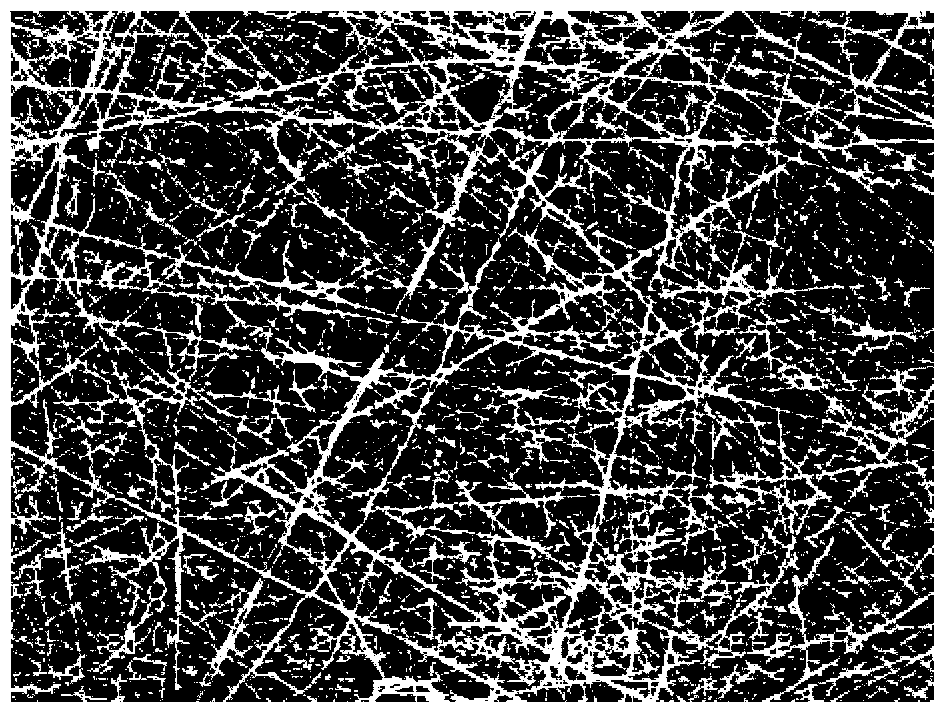

Image

Examples

Embodiment

[0028] A method for making an anti-smog nano window screen, the method steps are as follows:

[0029] (1) Preparation of electrospinning solution

[0030] Add polyamide 6 particles into a formic acid solution with a concentration of 98%, and stir at room temperature to completely dissolve the polyamide 6 particles to form an electrospinning solution with a polyamide 6 mass concentration of 13%;

[0031] (2) Electrospinning

[0032] Use the electrospinning device to spray the above prepared electrospinning solution on the PET polyester fiber mesh substrate, and form a layer density of 1.25g / m2 or 2.5g / m2 on the PET polyester fiber mesh substrate. The nanofibrous membrane has an average fiber diameter of 217nm and a surface pore diameter of 234nm.

[0033] The above electrospinning device adopts the DT-200 electrospinning machine produced by Dalian Dingtong Technology Development Co., Ltd.

[0034] When the electrospinning device is working, the voltage of the high voltage ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Fiber average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com