Functional fabric production method

A production method and functional technology, applied in the field of home textile fabrics, can solve the problem of not having a good functional fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

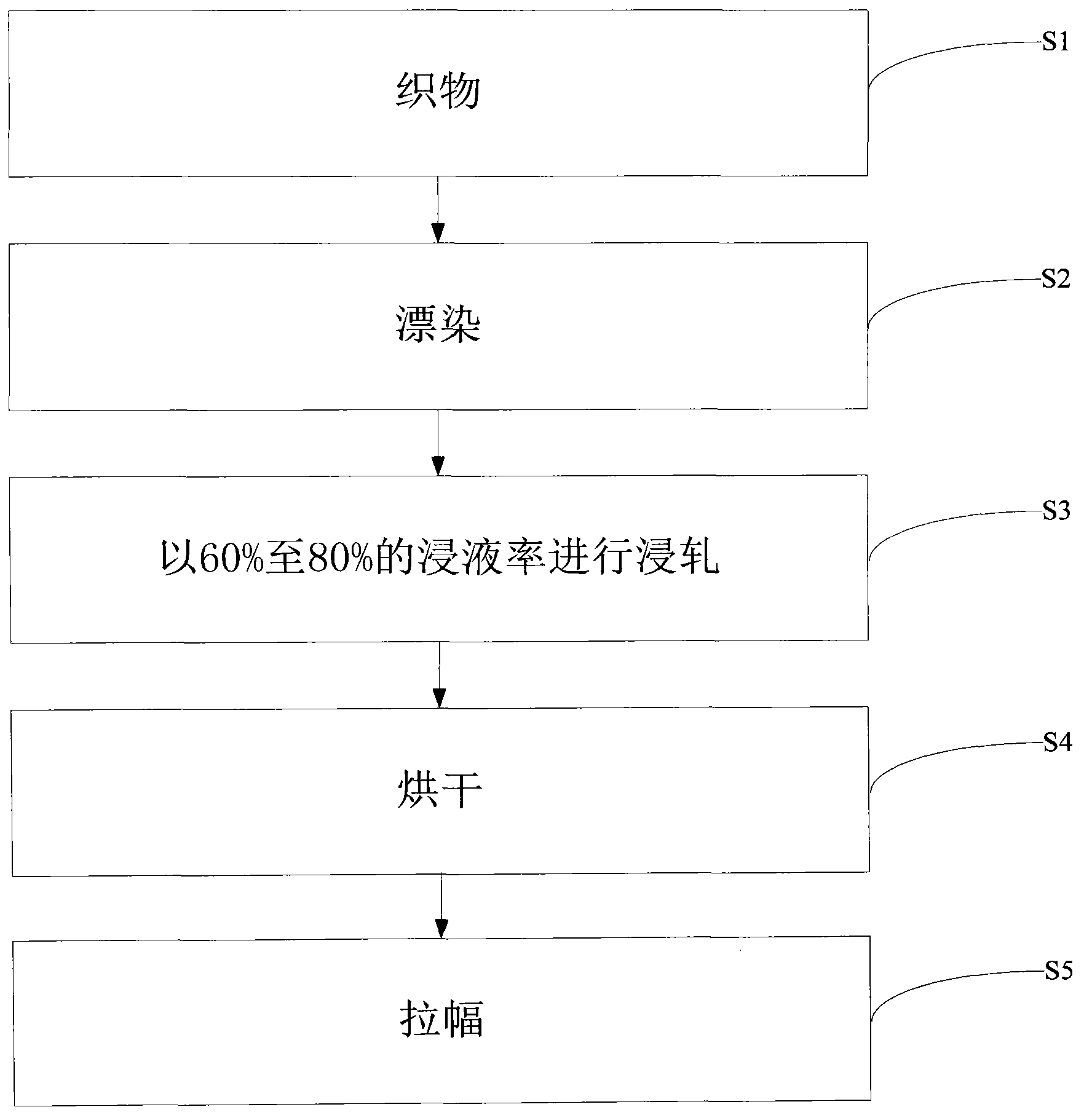

Method used

Image

Examples

Embodiment 1

[0043] The antibacterial fabric produced by the method of the invention is a highly washable antibacterial fabric, which has good safety, broad-spectrum and high-efficiency antibacterial properties and excellent washing resistance. It can produce bed sheets, underwear, towels, cloth, interior decoration products, air filter materials, etc. with antibacterial, deodorant, and anti-mildew functions. It has extremely high antibacterial, deodorant, anti-mildew, and anti-itch effects, and is effective against MRSA, Staphylococcus aureus, Staphylococcus epidermidis, Neisseria gonorrhoeae (domestic epidemic strains), Neisseria gonorrhoeae (international standard drug-resistant strains), Klebsiella pneumoniae in contact with fabrics , Escherichia coli, Pseudomonas aeruginosa, Bacillus subtilis, Bacillus cereus, Candida albicans, Epidermophyton flocculus, Trichophyton gypsum, Trichophyton rubrum, Penicillium, Aspergillus niger and other harmful bacteria have excellent antibacterial Func...

Embodiment 2

[0057] The aroma finishing agent SCM used in the aromatherapy sleep aid fabric produced by the method of the present invention is a kind of fully encapsulated microcapsule fragrance, which releases fragrance slowly through friction or the like. Fragrance finishing agent SCM is non-toxic to human body, non-irritating to skin, and has no allergic reaction.

[0058] The appearance of the fragrance finishing agent SCM is a milky white slurry liquid, the pH value is 7, the particle size is less than 1 μm, the active ingredient content is 40%, and it can be dispersed in water.

[0059] Processing and production method:

[0060] fabric;

[0061] Padding fragrance finishing agent solution, the dipping rate is 70% to 80%;

[0062]Dry at a temperature of 80°C to 100°C.

[0063] The formula ratio of above-mentioned fragrance finishing agent solution is:

[0064] Fragrance finishing agent: 5% to 10%;

[0065] Binder: 15% to 20%;

[0066] Thickener: 1% to 2%.

Embodiment 3

[0068] The skin is the most important safety barrier of the human body, so maintaining skin health is very necessary. The collagen skin care fabric produced by the method of the present invention has the following functions: it helps to promote skin health, nourishes and moisturizes the skin, has the functions of skin care, beauty, health and beauty, etc. Wearing skin care and arranging clothes can make the skin full of elasticity and luster, which is beneficial to the skin of the human body Good protection.

[0069] The skin care finishing agent TSD used in the collagen skin care fabric is mainly composed of natural chitosan acid extracted from natural silk, aloe extract and silk fibroin. It is a very safe skin care finishing agent and has no irritation to the skin. No allergic reaction, does not affect the strength, hand, breathability and rewetting of the fabric. The collagen skin care fabric has good comfort, excellent moisture absorption and moisturizing properties, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com