Tuckahoe biscuit and preparation method thereof

A technology of tuckahoe biscuits and tuckahoe powder is applied in the directions of baking, baked goods, food science, etc., which can solve the problems of complex biscuit components, and achieve the effects of obvious health care effect, good taste and easy absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

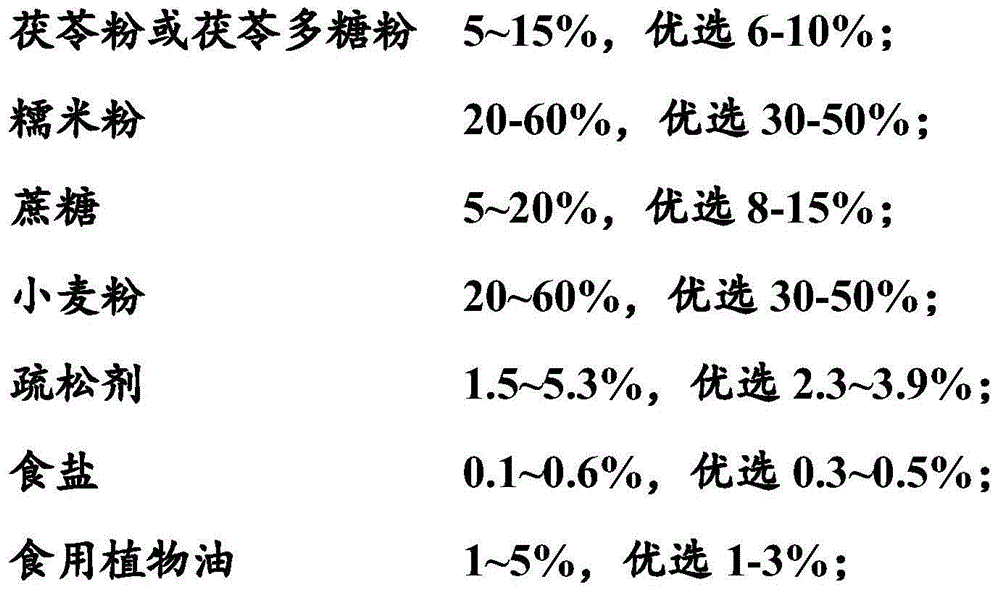

Method used

Image

Examples

preparation example 1

[0044] Preparation of Ultrafine Poria Cocos Polysaccharide Powder

[0045] Take 1 kg of Poria cocos and crush it, soak it in 2 L of 0.5 mol / L NaOH aqueous solution at room temperature, apply ultrasonic waves with a power of 90 W, and extract for 1 hour. The resulting extract was concentrated according to the ratio of extract:concentrate=10:1, the concentrate was precipitated with 95% ethanol, allowed to stand overnight, filtered, and the precipitate was washed successively with absolute ethanol, acetone and ether. The precipitate was ultrafinely pulverized using a stirring mill, and the particle diameter of the obtained ultrafine pachyphyllan powder was 5 μm, and the water contact angle θ=80°.

preparation example 2

[0047] Preparation of Modified Ultrafine Poria Cocos Polysaccharide Powder

[0048] Mix the ultrafine pachyrhiza powder obtained in Preparation Example 1 with water, heat it to boiling under vigorous stirring, grind it into a slurry through a colloid mill, and then spray dry it to obtain a modified ultrafine pachymosa powder. The particle diameter of the obtained modified ultrafine pachyrhiza powder is 4 μm, and the water contact angle θ=20°.

preparation example 3

[0050] Preparation of Nano Poria Cocos Powder

[0051] Take 1 kg of Poria cocos and crush it, soak it in 2 L of 0.5 mol / L NaOH aqueous solution at room temperature, apply ultrasonic waves with a power of 90 W, and extract for 1 hour. The resulting extract was concentrated according to the ratio of extract:concentrate=10:1, the concentrate was precipitated with 95% ethanol, allowed to stand overnight, filtered, and the precipitate was washed successively with absolute ethanol, acetone and ether. The precipitate is pulverized by an ultrafine pulverizer, and the particle diameter of the obtained nano-pachypolysaccharide powder is 45nm, and the water contact angle θ=30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com