A kind of water-based coating for magnesite handicraft and preparation method thereof

A technology for water-based coatings and handicrafts, applied in coatings and other directions, it can solve the problems of difficult adhesion of coatings, affect product appearance, low surface tension, etc., and achieve the effects of improving adhesion, rapid spreading and wetting, and good film-forming properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

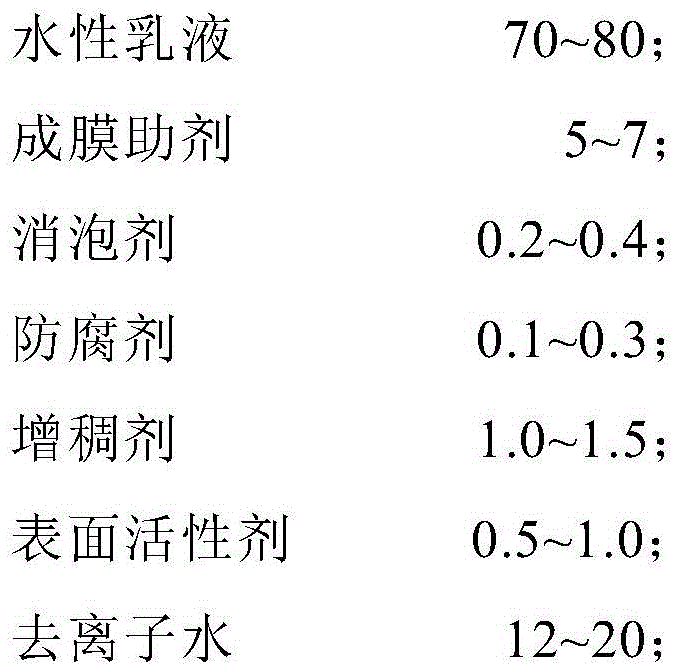

[0041] A preparation method of water-based paint for magnesite handicrafts, the method may further comprise the steps:

[0042] (1) According to the formula requirements, 40 kg of modified acrylate emulsion 1 (glass transition temperature is 20-22°C) and 35 kg of modified acrylate emulsion 2 (glass transition temperature is 50-52°C) are put into the dispersion Tank, start stirring, under the speed of 300-500r / min, put in 4 kg of propylene glycol butyl ether, 2 kg of dipropylene glycol propyl ether, 0.2 kg of defoamer, 0.5 kg of surfactant, 18 kg of deionized water, thickener 1.0 kg, 0.1 kg preservative, keep stirring for 15-30 minutes;

[0043] (2) Regulate the viscosity of the solution obtained in step (1) with deionized water, so that the time for the solution obtained in step (1) to flow through the ISO6# outflow cup is 30~50s;

[0044] (3) Weigh and pack to obtain the water-based paint for magnesite handicrafts.

Embodiment 2

[0046] A preparation method of water-based paint for magnesite handicrafts, the method may further comprise the steps:

[0047] (1) According to the formula requirements, 30 kg of modified acrylate emulsion 1 (glass transition temperature is 20-22°C) and 45 kg of modified acrylate emulsion 2 (glass transition temperature is 50-52°C) are put into dispersion Tank, start stirring, under the speed of 300-500r / min, put in 3 kg of propylene glycol butyl ether, 2 kg of dipropylene glycol propyl ether, 0.2 kg of defoamer, 0.8 kg of surfactant, 18 kg of deionized water, thickener 1.0 kg, 0.1 kg preservative, keep stirring for 15-30 minutes;

[0048] (2) Regulate the viscosity of the solution obtained in step (1) with deionized water, so that the time for the solution obtained in step (1) to flow through the ISO6# outflow cup is 30~50s;

[0049] (3) Weigh and pack to obtain the water-based paint for magnesite handicrafts.

Embodiment 3

[0051] A preparation method of water-based paint for magnesite handicrafts, the method may further comprise the steps:

[0052] (1) According to the formula requirements, 20 kg of modified acrylate emulsion 1 (glass transition temperature is 20-22°C) and 55 kg of modified acrylate emulsion 2 (glass transition temperature is 50-52°C) are put into dispersion Tank, start stirring, at the speed of 300-500r / min, put in 3 kg of propylene glycol butyl ether, 2 kg of dipropylene glycol propyl ether, 0.3 kg of defoamer, 1.0 kg of surfactant, 18 kg of deionized water, thickener 1.0 kg, 0.1 kg preservative, keep stirring for 15-30 minutes;

[0053] (2) Regulate the viscosity of the solution obtained in step (1) with deionized water, so that the time for the solution obtained in step (1) to flow through the ISO6# outflow cup is 30~50s;

[0054] (3) Weigh and pack to obtain the water-based paint for magnesite handicrafts.

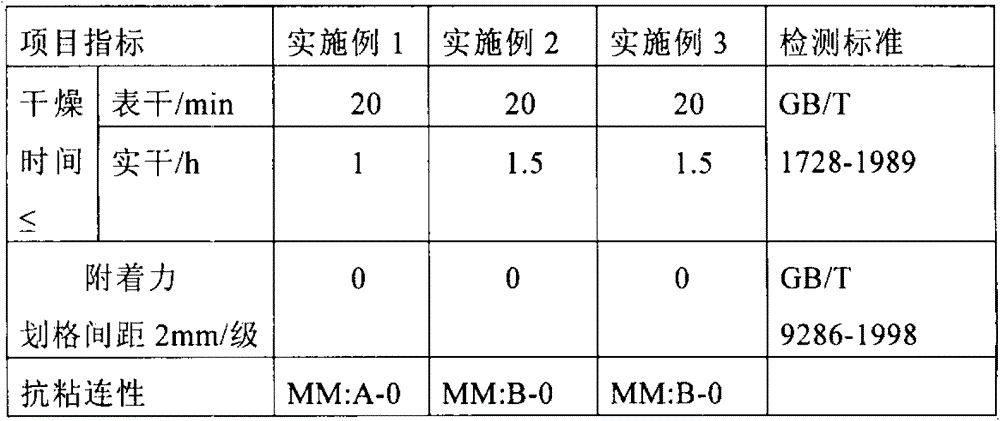

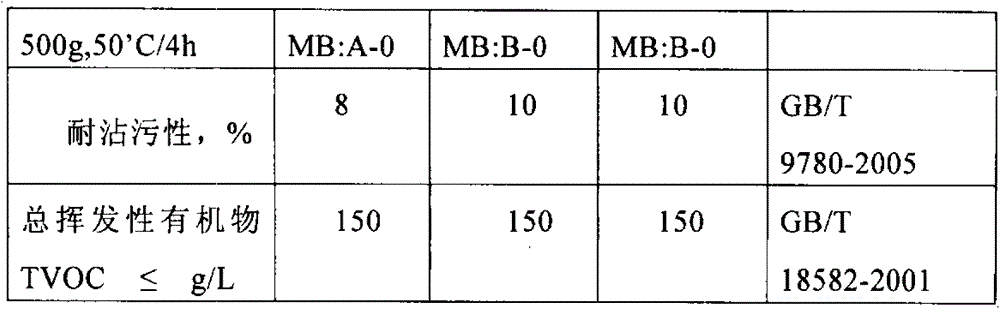

[0055] The water-based paint prepared by embodiment 1~embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com