Method for preparing nitrogen-enriched functional gradient metal ceramic by low pressure nitriding method

A cermet and functional gradient technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of inhibiting the industrial application of nitrogen-rich functional gradient cermet materials on the surface, low production efficiency, and large investment in equipment, etc. problems, to achieve the effect of easy industrial transformation, low production cost and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A method for preparing nitrogen-enriched functionally graded cermets by a low-pressure nitriding method of the present invention is to put the sintered cermets into a vacuum integrated furnace, and raise the temperature to the preset nitriding temperature at a certain heating rate under the vacuum sintering state. temperature; when the temperature of the furnace body reaches the preset nitriding temperature, nitrogen partial pressure sintering process is used for nitriding, and by controlling the partial pressure and holding time, and then cooling under nitrogen atmosphere, the surface nitrogen-enriched functional gradient cermet is obtained .

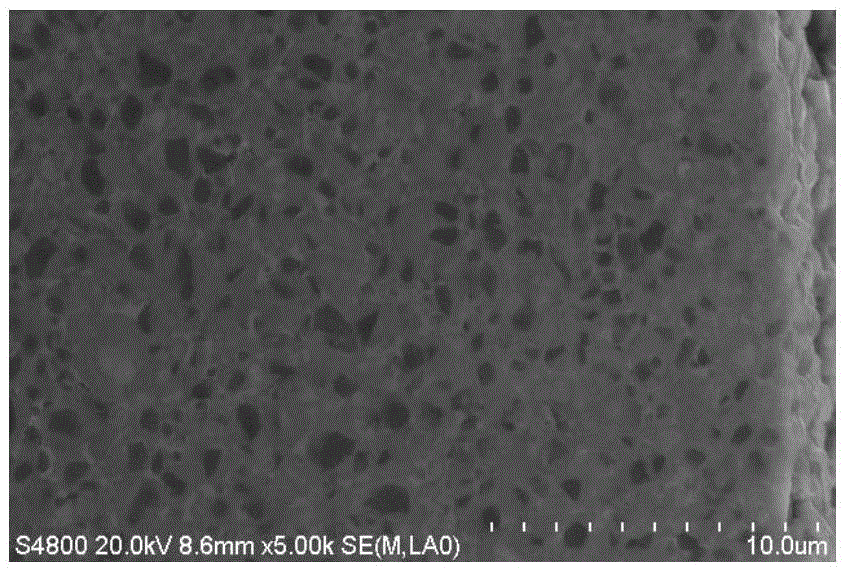

[0022] The prepared nitrogen-rich functionally graded cermet has a composition gradient from the surface to the inside, the surface is rich in N, poor in Co and / or Ni and other binder phases, the alloy has a bending strength of 2200-2500 MPa, and the thickness of the surface gradient layer is 5 ~15 μm.

[0023] A method for pre...

Embodiment 1

[0028] (1) Ingredients + wet grinding: According to the 1# formula in Table 1, select Ti(CN) powder with an average particle size of 1-1.5um, and other powders with an average particle size of about 1um as raw materials, and use alcohol as the grinding medium for ingredients. Using paraffin wax as a molding agent, the amount of paraffin wax added accounts for 4% of the total material weight, the grinding ball to material ratio is 7:1, and the grinding time is 72 hours.

[0029] (2) Spray drying: spray-dry the slurry obtained in step (1) to obtain an RTP mixture with an average particle size of about 100um.

[0030] (3) Molding + sintering: the mixture obtained in step (2) is pressed at a pressure of 150 MPa, and then sintered in a vacuum furnace at a sintering temperature of 1400-1500° C. to obtain a sintered compact alloy.

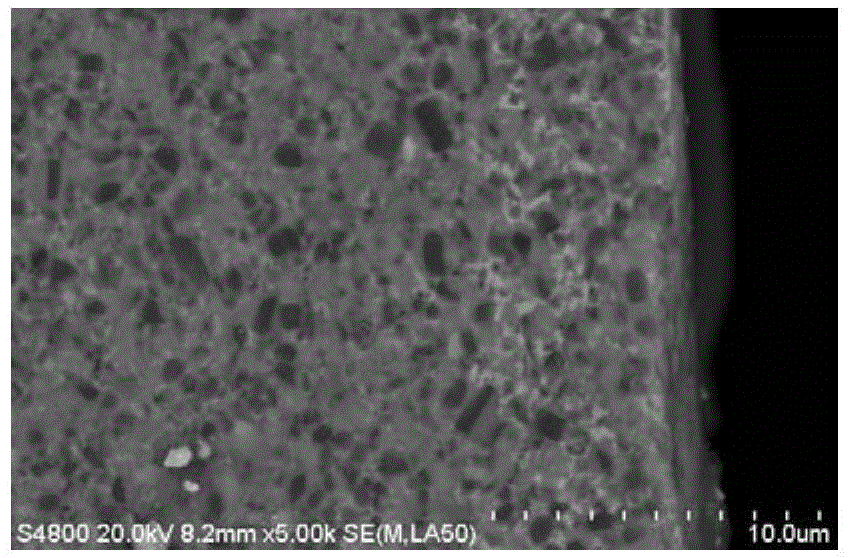

[0031] (4) Gradient treatment: put the cermet alloy obtained in step (3) into a vacuum integrated furnace, raise the temperature to 1200°C under vacuum c...

Embodiment 2

[0036] The composition of the cermet alloy used in the present embodiment is the same as that in the first embodiment, and its gradient treatment process is as follows:

[0037] Put the cermet alloy into a vacuum integrated furnace, raise the temperature to 1300°C under vacuum at a sintering temperature of 5°C / min, and then switch to partial pressure sintering, the partial pressure is 6000Pa, the sintering atmosphere is a nitrogen atmosphere, and the purity of nitrogen is 99%, and the holding time is 6 hours, the surface nitrogen-enriched functional gradient cermet alloy can be obtained, wherein the thickness of the surface gradient layer is about 15 μm.

[0038] The performance of the surface gradient cermet alloy prepared by the above process is shown in Table 3.

[0039] table 3

[0040]

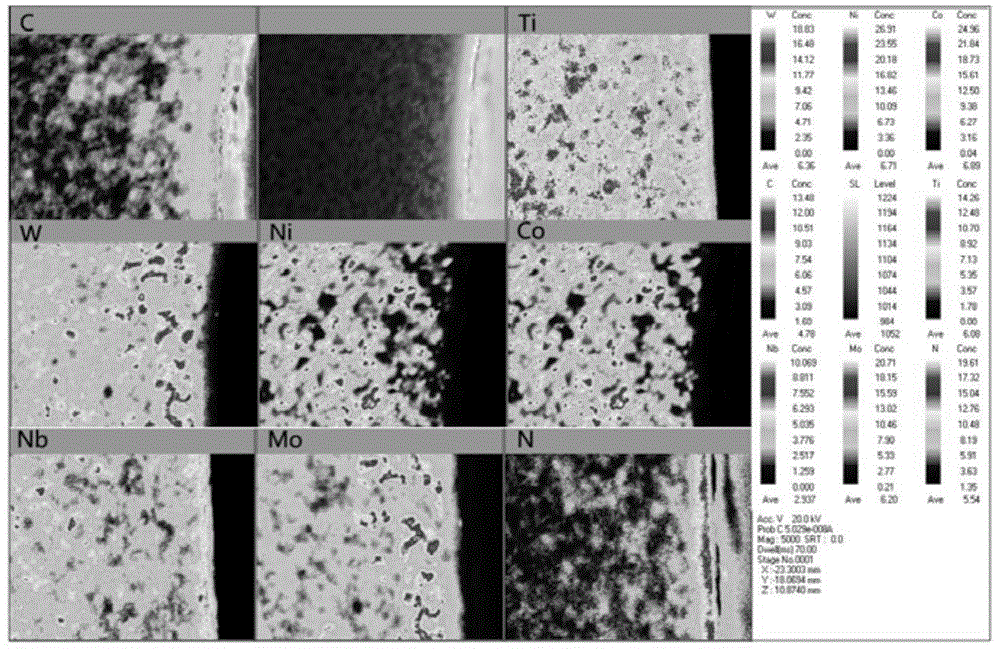

[0041]The surface gradient layer and the matrix were analyzed by EDS, and the composition differences are shown in Table 4.

[0042] Table 4

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com