High voltage transmission cable

A high-voltage transmission and cable technology, applied in the direction of power cables, power cables for overhead applications, cables, etc., can solve the problems of not very ideal, slow cable manufacturing speed, low efficiency, etc., to prevent external radiation and shorten delivery Cycle, the effect of excellent machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

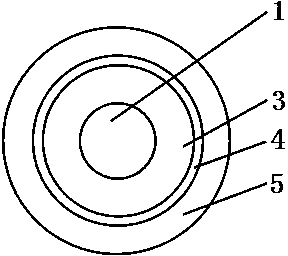

[0062] please see figure 1, a high-voltage transmission cable, which includes a conductor 1, an insulating layer 3 coated outside the conductor by extrusion molding, a semiconductor outer shield layer 4 coated outside the insulating layer, and an outer semiconductor shield layer coated by extrusion molding Outer sheath layer 5; It is characterized in that described semiconductor outer shielding layer comprises following raw material by weight:

[0063] Polyethylene or polypropylene or polyvinyl chloride: 40 to 60 parts;

[0064] Conductive carbon fiber: 25-35 parts;

[0065] Oxidized polyethylene: 20-30 parts;

[0066] Commercially available antioxidant for cable materials with model number 1010: 1-2 parts;

[0067] Magnesium hydroxide: 3-5 parts;

[0068] Titanium dioxide: 3-5 parts;

[0069] Carbon black: 3-5 parts;

[0070] Dioctyl terephthalate: 1-3 parts.

Embodiment 2

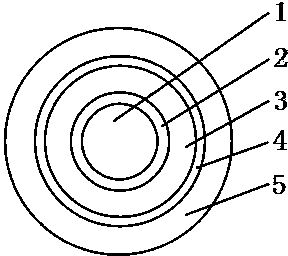

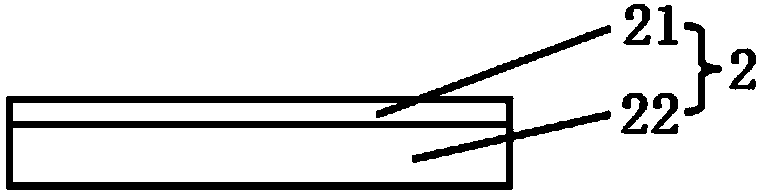

[0072] please see figure 2 with image 3 , a high-voltage transmission cable, which includes a conductor 1, a semiconductor inner shielding layer 2 coated outside the conductor, an insulating layer 3 coated outside the semiconductor inner shielding layer by extrusion molding, and an insulating layer coated outside the insulating layer The semiconductor outer shielding layer 4, the sheath layer 5 coated outside the semiconductor outer shielding layer by extrusion; it is characterized in that the semiconductor inner shielding layer and the semiconductor outer shielding layer all include the following raw materials by weight:

[0073] Polyethylene or polypropylene or polyvinyl chloride: 40 to 60 parts;

[0074] Conductive carbon fiber: 25-35 parts;

[0075] Oxidized polyethylene: 20-30 parts;

[0076] Commercially available antioxidant for cable materials with model number 1010: 1-2 parts;

[0077] Magnesium hydroxide: 3-5 parts;

[0078] Titanium dioxide: 3-5 parts;

[00...

Embodiment 3

[0092] please see Figure 4 , a high-voltage transmission cable, which includes a cable core, a semiconductor outer shielding layer 4 coated outside the cable core, a sheath layer 5 coated outside the semiconductor outer shielding layer by extrusion molding, and the cable core is composed of Composed of three insulated wires, the gap between the cable cores is filled with insulators 6, and each insulated wire includes a conductor 1, a semiconductor inner shield layer 2 coated outside the conductor, and an insulation layer coated outside the semiconductor inner shield layer by extrusion molding. Layer 3; it is characterized in that the semiconductor inner shielding layer and the semiconductor outer shielding layer all include the following raw materials in parts by weight:

[0093] Polyethylene or polypropylene or polyvinyl chloride: 40 to 60 parts;

[0094] Conductive carbon fiber: 25-35 parts;

[0095] Oxidized polyethylene: 20-30 parts;

[0096] Commercially available ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com