Method for recovering ammonium chloride in rare-earth ammonium salt wastewater to prepare agricultural chemical fertilizer

A technology for ammonium chloride and wastewater, applied in ammonium salt fertilizers, chemical instruments and methods, ammonium halide, etc., can solve the problems affecting the treatment of ammonia nitrogen wastewater and the difficulty of effectively selling ammonium salts, so as to improve fertilizer efficiency and achieve good market sales Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

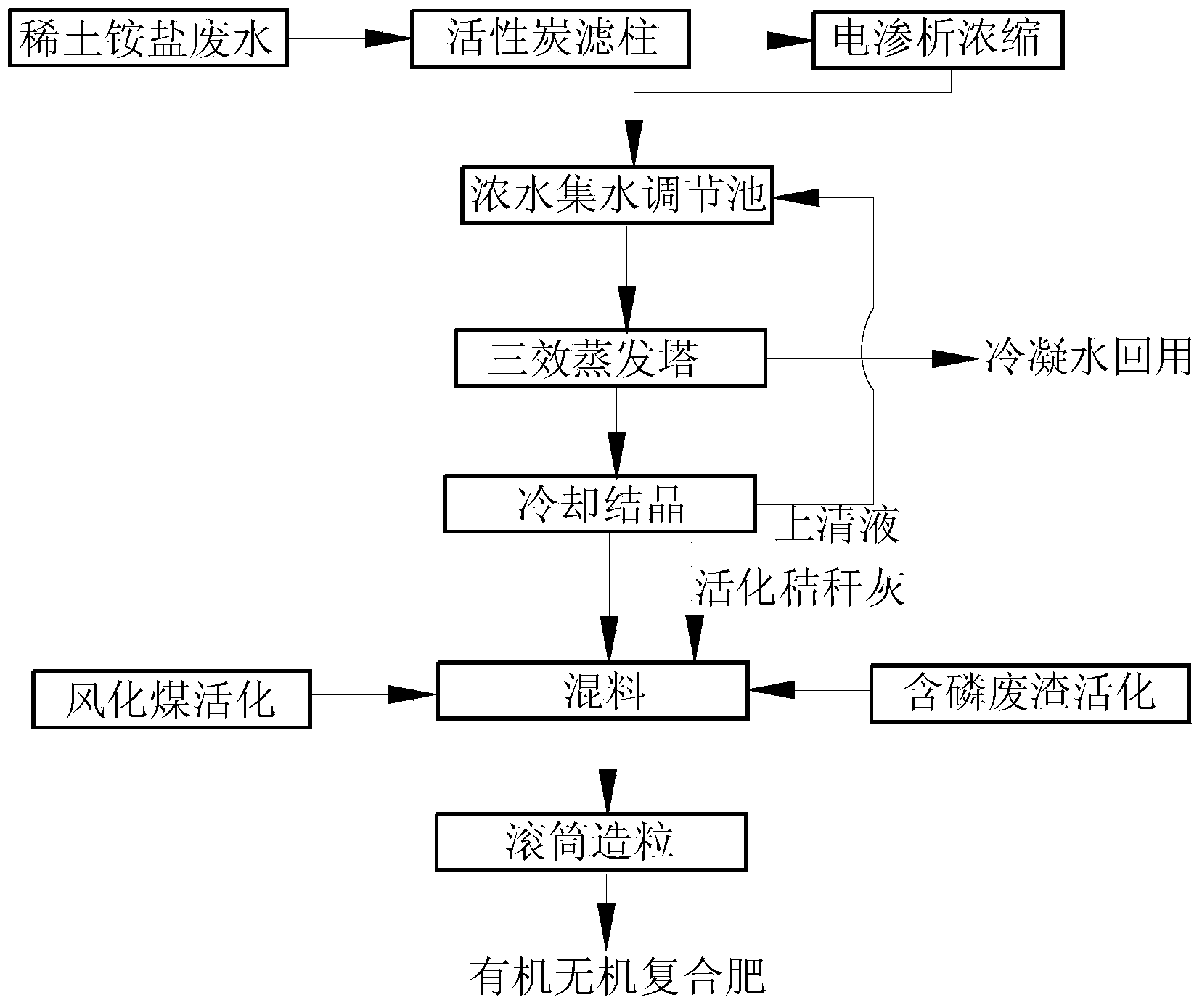

[0026] A method of reclaiming ammonium chloride in rare earth ammonium salt wastewater to prepare agricultural chemical fertilizers, such as figure 1 As shown, firstly, 8% ammonium salt wastewater is pretreated by an activated carbon filter column to reduce the concentration of organic matter in the wastewater to 0.4mg / L. 12.5%, adjust the pH of the concentrated solution to 4, then enter the three-effect evaporation crystallizer to further concentration to 47%, then the concentrated slurry enters the cooling crystallization tank for cooling and crystallization, when the temperature reaches 27°C, start the centrifuge to recover ammonium chloride For solids, 60% of the mother liquor is used for granulation of organic and inorganic compound fertilizers, and the remaining 40% of the mother liquor is returned to the three-effect evaporation concentration device.

[0027] Activation treatment of phosphorus-containing waste residue from gelatin factory: place the phosphorus-containin...

Embodiment 2

[0032] The 6% ammonium salt wastewater is firstly pretreated by activated carbon filter column to reduce the concentration of organic matter in the wastewater to 0.5mg / L, and then enters the electrodialysis device after being filtered by the security filter device to increase the concentration of ammonium chloride in the wastewater to 11%. The pH of the concentrated solution is adjusted to 4, and then enters the three-effect evaporation crystallizer to further increase the concentration to 46%. Then the concentrated slurry enters the cooling crystallization tank for cooling and crystallization. When the temperature reaches 27°C, start the centrifuge to recover the ammonium chloride solid, 60 % of the mother liquor is used for the granulation of organic and inorganic compound fertilizers, and the remaining 40% of the mother liquor is returned to the three-effect evaporation concentration device.

[0033] Maturation of phosphorus-containing waste residues from gelatin factories: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com