Preparation method of aluminium oxide honeycomb ceramics

A technology of honeycomb ceramics and alumina, which is applied in the field of materials, can solve problems such as difficult filtration, and achieve the effects of high production efficiency, convenient operation and control, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of alumina honeycomb ceramic by extrusion molding and its properties

[0037] Take 216g of alumina powder with a particle size of 3μm, 60g of kaolin, and 9g of CaCO 3 , 9gBaCO 3 And 6g wollastonite, mix well to obtain a powder mixture. Mix water, polyvinyl alcohol and polyhydroxyglycolic acid at a weight ratio of 70:10:20, stir to obtain a uniform solution, mix the solution with the above powder mixture at a weight ratio of 100:70, and mix at room temperature and pressure. The mixing machine (BL-6175-B) is fully mixed at room temperature for 0.75 hours and aged for 3 hours at room temperature and pressure to obtain mud. The mud is filtered and purified through a 60-mesh sieve, and the honeycomb green is extruded through a honeycomb ceramic extruder (BL-6177), and dried at 40°C for 6 hours. After drying, the sample is degummed at 600°C to remove organic matter for 2 hours, and then discharged The glued green honeycomb is placed in a muffle furnace (BT...

Embodiment 2

[0039] Example 2 Preparation and properties of alumina honeycomb ceramics by gel injection molding

[0040] The monomer acrylamide and the crosslinking agent N,N'-methylenebisacrylamide are dissolved in water, the monomer concentration is 15wt%, and the crosslinking agent concentration is 0.5wt% to form a monomer premix. Add 140g of alumina powder with a particle size of 1μm, 40g of kaolin, and 6g of MgCO to the premix 3 , 6g BaCO 3 And 4g of talc, 2g of ammonium citrate as the dispersant, stir to obtain a homogeneous ceramic slurry, add 25μl of the catalyst N,N,N',N'-tetramethylethylenediamine to the above slurry, then stir evenly, and then Add 50μl of initiator 8% ammonium persulfate solution, stir well and then pour into the mold immediately, and insert the self-made multi-needle hole-forming mold (needle φ=2mm, 4 holes / cm2) into the slurry, and wait until the slurry is gel After being shaped, it is demoulded to obtain a honeycomb green body. Put the wet body in an oven at 50...

Embodiment 3

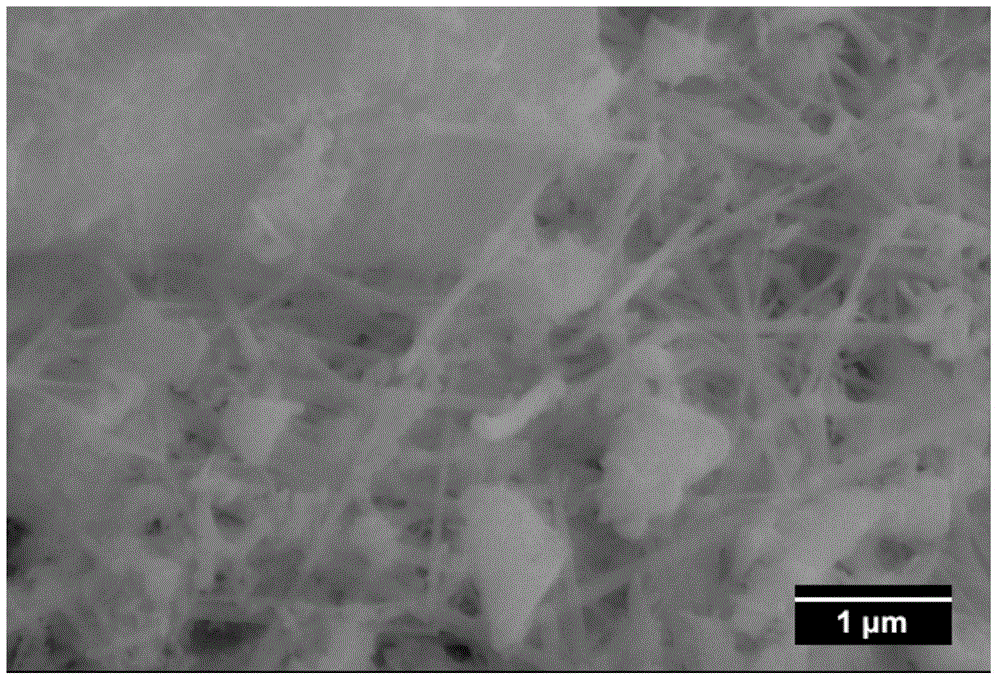

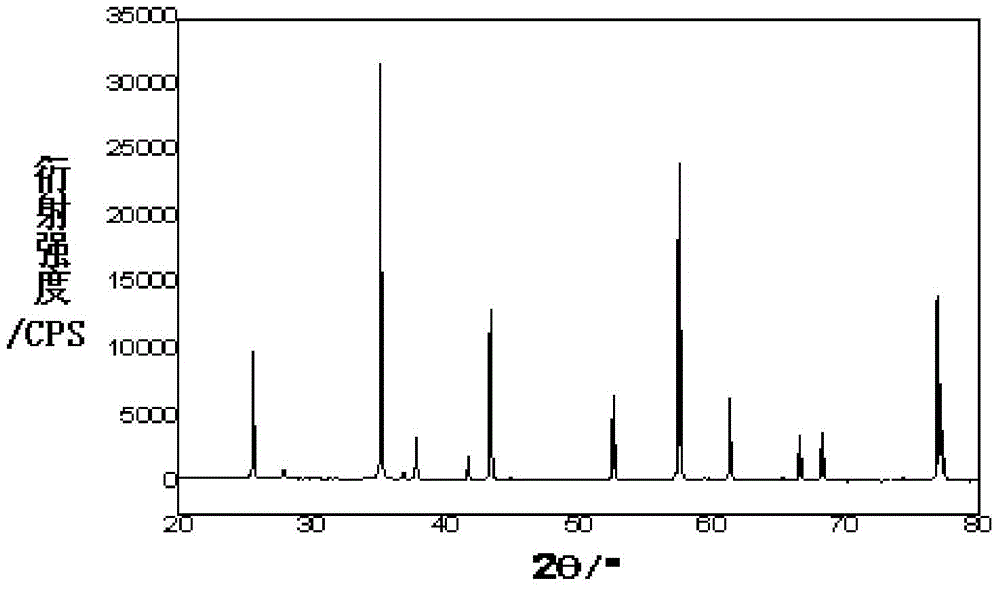

[0042] Example 3 Preparation and properties of alumina honeycomb ceramics by dry pressing

[0043] Combine 210g of alumina powder with a particle size of 3μm, 60g of kaolin, and 6g of BaCO 3 Mix it with 18g of dolomite powder uniformly, add alcohol and wet grinding with a grinding ball for 24 hours, dry and sieve, add 5wt% paraffin based on the sieved material as a forming agent, press in a steel mold to form a long sample (10cm in length) , Width 5cm, height 5cm), the pressure is 100MPa, and then press into the self-made multi-needle hole-forming mold (needle φ=2mm, 4 holes / cm²) and pull out to obtain a honeycomb body, and place the honeycomb body Put it in the debinding furnace and heat it up to 800℃ and keep it for 3 hours to dewax. Put the dry body into the muffle furnace (BTF-1700C) and heat it up to 1600℃ for 2.5 hours at a rate of 10℃ / min. The alumina honeycomb ceramic with the structure of "the inner wall of the pores stretched whiskers" is obtained. The SEM photos and X...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Transverse compressive strength | aaaaa | aaaaa |

| Axial compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com