A Dielectric-Piezoelectric Composite Film Phase Shifter

A piezoelectric composite, dielectric film technology, applied in circuits, electrical components, waveguide-type devices, etc., can solve the problems of large microwave loss, high power consumption, and high working field strength, and achieve low driving voltage, stable performance, and low power consumption. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] The function of the phase shifter is to shift the phase of the signal by an angle. Its working principle is different according to different components. Such as a transistor circuit, a control signal can be added to the input to control the phase shift; in some circuits, the delay of the resistance-capacitance circuit is used to achieve phase shift; in the single-chip control system, the internal timer can also be used to achieve the purpose of phase shift.

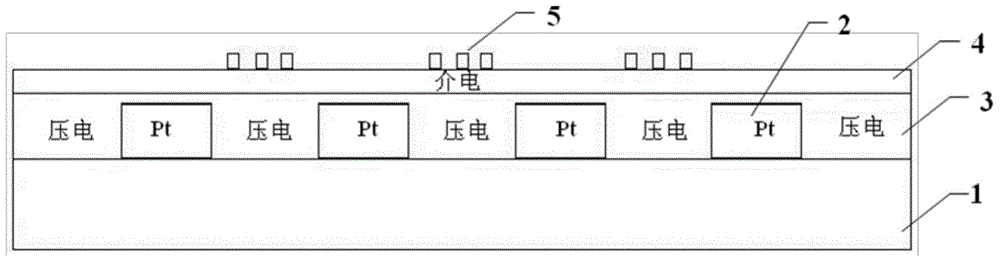

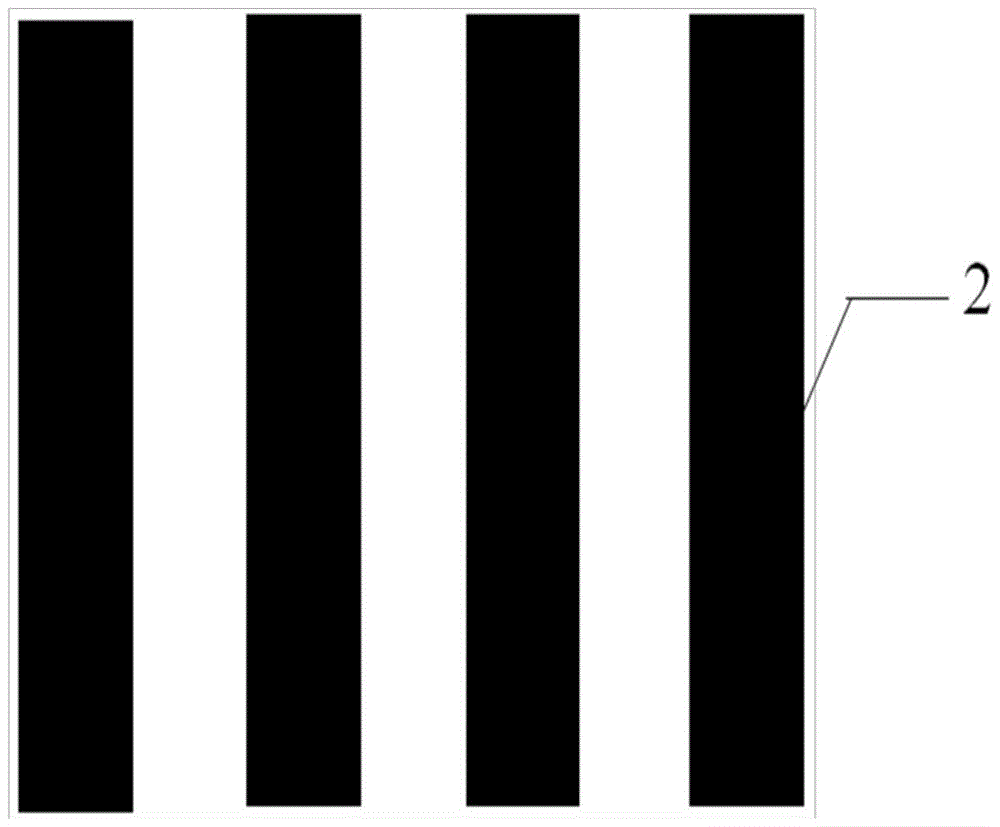

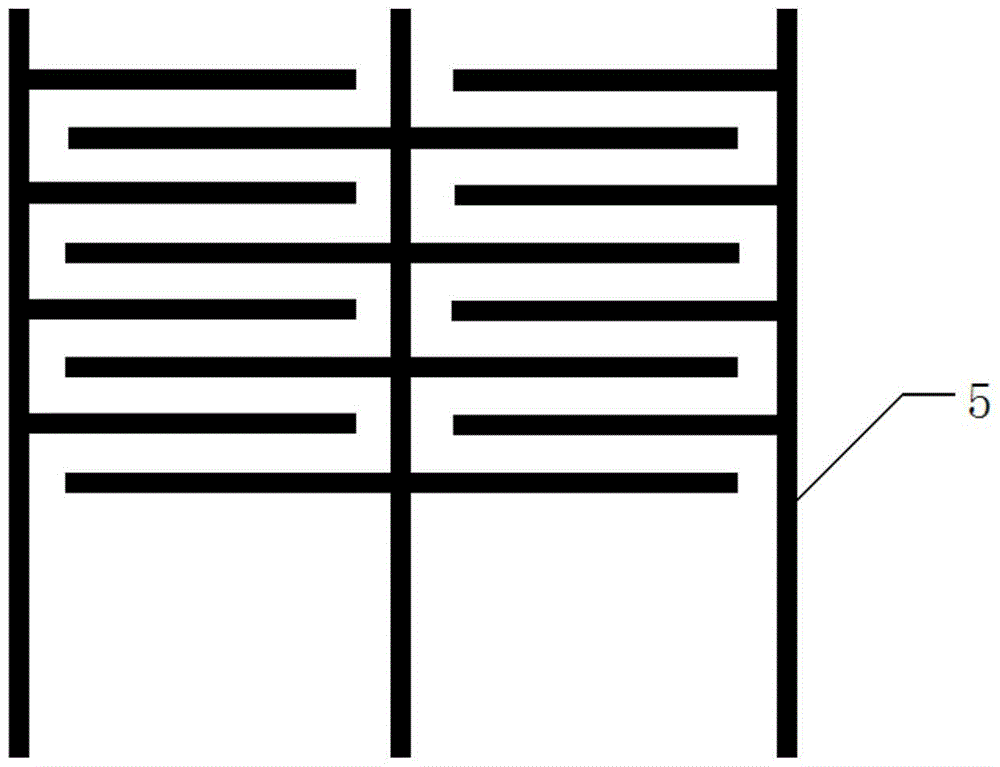

[0033] Refer to attached figure 1 , the dielectric-piezoelectric composite thin-film phase shifter of the present invention, which includes a dielectric substrate 1, a strip-shaped drive electrode 2, a piezoelectric film 3, a dielectric film 4 and an interdigitated coplanar waveguide transmission line 5, and a strip-shaped drive electrode 2 is set on the dielectric substrate 1, the piezoelectric film 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com