Method for preparing detonation nanometer diamond dispersion

A technology of nano-diamond and dispersion liquid, which is applied in the field of preparation of nano-diamond dispersion liquid, can solve the problems of not being suitable for various media, no yield report, and few research reports, etc., and achieves easy storage and transportation, and high yield , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of detonation nano-diamond dispersion liquid (polar medium) of the present invention, comprises the following steps:

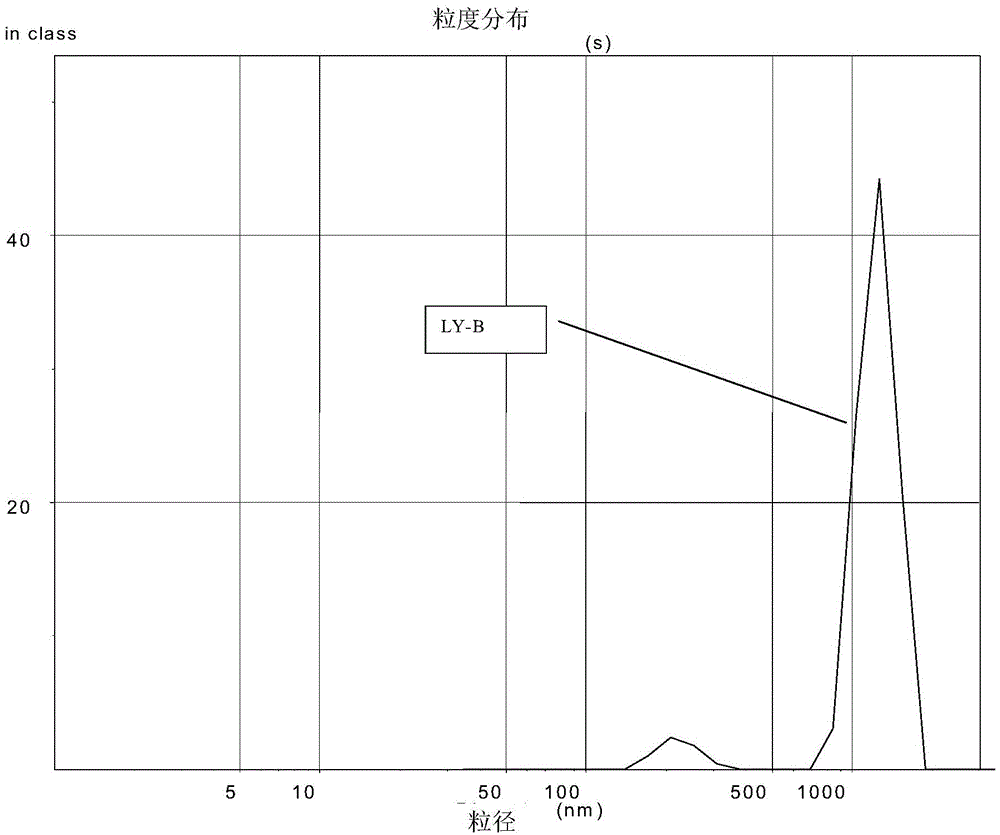

[0039] (1) First take by weighing 56g of commercially available nano-diamonds (see figure 1 ) and 2.8g sodium octadecyl sulfate, after mechanical stirring or ultrasonic dispersion in deionized water, the mass fraction is 2% dispersion; When the pressure reaches 200Mpa, spray the diamond target plate at high speed through the injector to break the nano-diamond aggregates, and collect the nano-diamonds after wet mechanochemical deagglomeration;

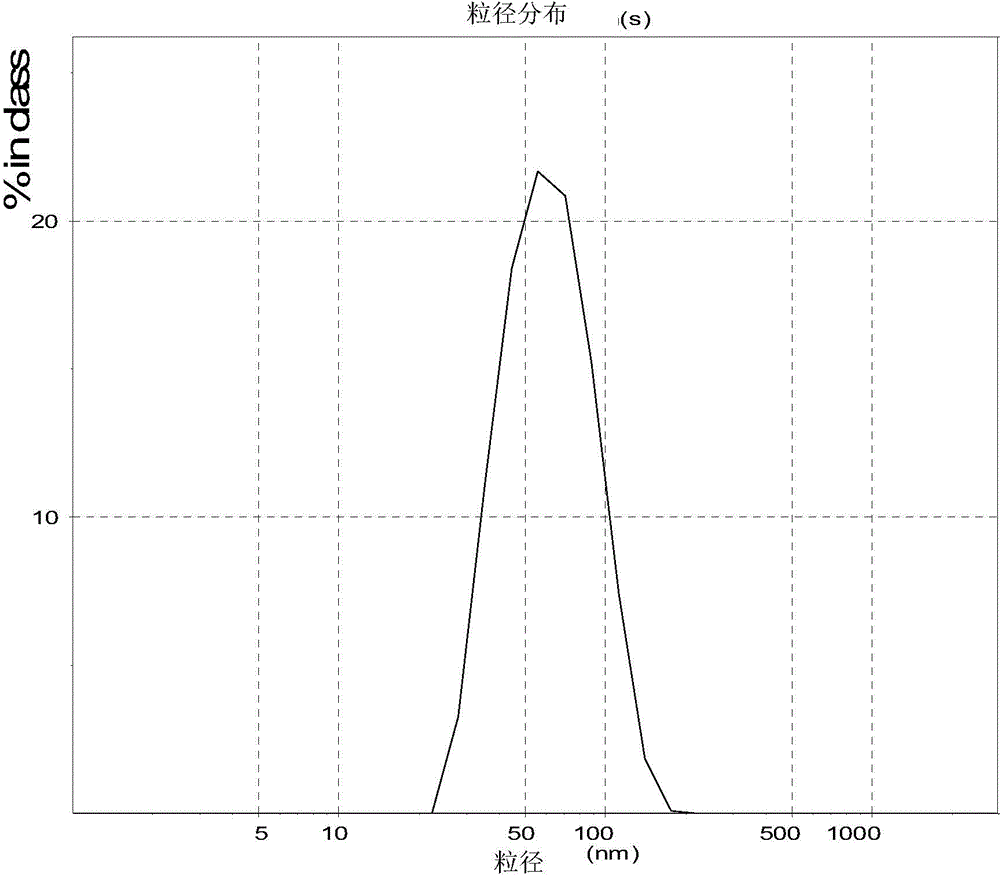

[0040] (2) the nano-diamond after the deagglomeration of step (1) is purified and removed with sulfuric acid, and centrifugal classification (450rpm, 40min) after cleaning is to remove coarse particles and other impurities to make the average particle size (D) of nano-diamond 50 ) is a water-based dispersion of 65nm (narrow particle size distribution) (see figure 2 ); the mass conc...

Embodiment 2

[0044] A kind of preparation method of detonation nano-diamond dispersion liquid (nonpolar medium) of the present invention, comprises the following steps:

[0045] (1) First weigh 50g of commercially available nano-diamonds (see figure 1 ), 2.0g sodium oleate and 2.0g glycerin, after mechanical stirring or ultrasonic dispersion in deionized water, make a dispersion with a mass fraction of 2%; Mechanochemical deagglomeration, collecting nano-diamonds after wet mechanochemical deagglomeration;

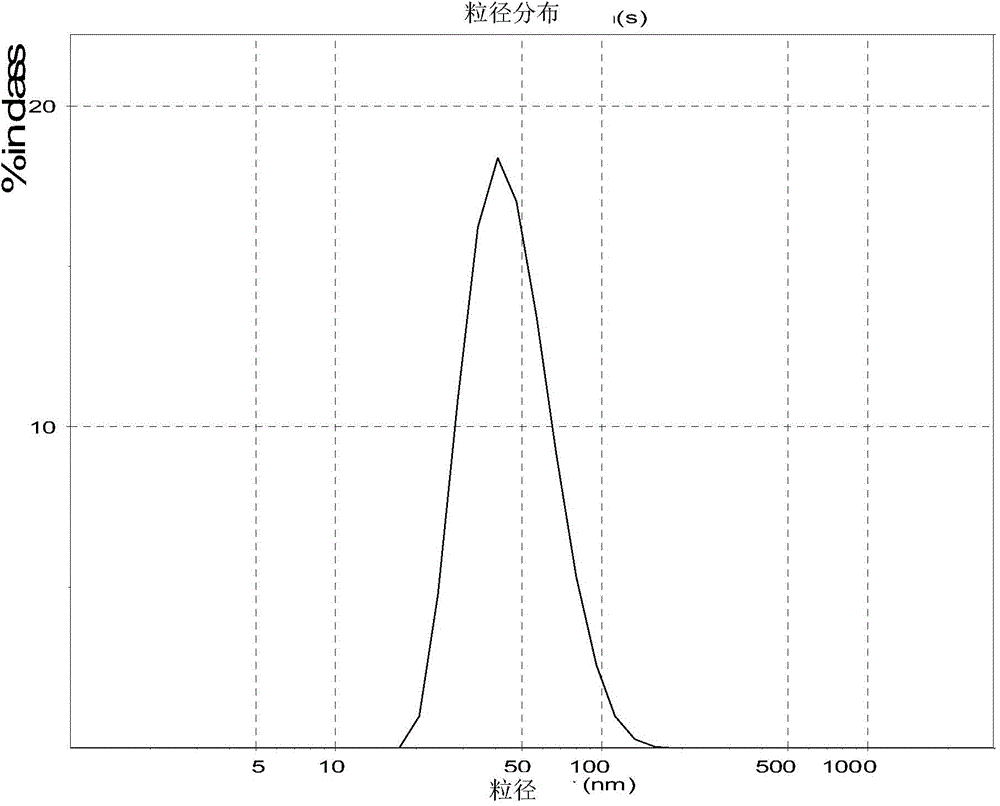

[0046] (2) Purify and remove impurities from the nano-diamonds deagglomerated in step (1) with hydrofluoric acid. After cleaning, use active cross-flow membrane separation equipment to classify to remove coarse particles (particle size exceeding 500nm) and other impurities. Active cross-flow The pressure applied by the type membrane separation equipment is 3.0bar, and the liquid flow velocity is 5.0m / s; the average particle size (D 50 ) is a water-based dispersion of 45nm (narrow part...

Embodiment 3

[0051] A kind of preparation method of detonation nano-diamond dispersion liquid (nonpolar medium) of the present invention, comprises the following steps:

[0052] (1) First take by weighing 56g of commercially available nano-diamonds (see figure 1 ) and 2.8g sodium hexametaphosphate, mechanically stirred or ultrasonically dispersed in deionized water to make a dispersion solution with a mass fraction of 2%; the dispersion solution of nano-diamonds was subjected to wet mechanochemical decomposition in deionized water by ball milling Agglomeration, collecting nanodiamonds after wet mechanochemical deagglomeration;

[0053] (2) the nano-diamond after the deagglomeration of step (1) is purified and removed with perchloric acid, and after cleaning, it is centrifugally classified to remove coarse particles (a particle diameter exceeding 500nm) and other impurities, and the average particle size (D) of the nano-diamond is made 50 ) is a water-based dispersion of 30nm (narrow parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com