Method for preparing nitride red phosphor

A technology of red fluorescent powder and nitride, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of unfavorable industrial mass production and practical application requirements, harsh conditions, complicated links, etc., and achieve easy mass production, simple equipment, Equipment requires simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

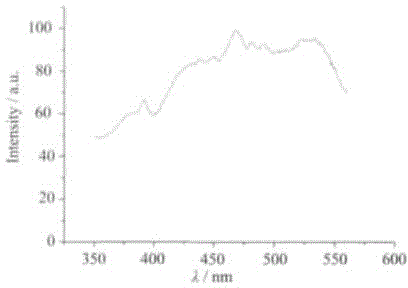

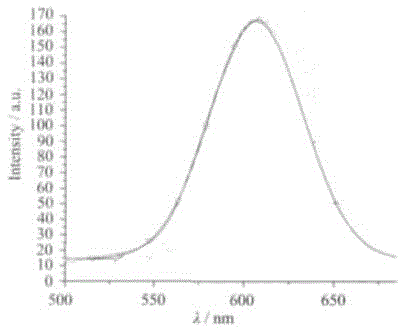

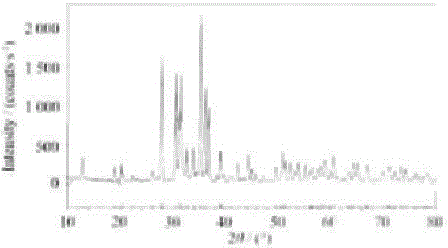

Image

Examples

Embodiment 1

[0047] Weigh out CaCN 2 2.400g, SrCO 3 4.207g, Eu 2 o 3 0.528g, Si 3 N 4 7.000g, AlN 0.038g and CaF 2 Add 0.024g of the above raw materials into a beaker and wet mix them with ethanol for 6 hours, put them in an oven and dry them for 24 hours, pass through a 120-mesh sieve, mix evenly, put them into a boron nitride crucible, and bake them at 1100°C in a nitrogen atmosphere for 10 hours. The roasted product was taken out and ground, passed through a 200-mesh sieve, put into a boron nitride crucible, and roasted at 1550°C for 12 hours in a nitrogen atmosphere. The resulting product was ground and sieved, washed with 10% nitric acid, then washed with deionized water and dried to obtain Ca 0.95 Sr 0.95 Si 5 N 8 :Eu 0.1 Nitride red phosphor.

Embodiment 2

[0049] Weigh out CaCN 2 2.160g, SrCO 3 3.986g, Eu 2 o 3 1.056g, Si 3 N 4 7.000g, AlN 0.035g and CaF 2 Add 0.026g of the above raw materials into a beaker and wet mix them with ethanol for 6 hours, put them in an oven to dry for 24 hours, pass through a 120-mesh sieve and mix evenly, put them into a boron nitride crucible, put them into a nitrogen atmosphere and bake them at 1510°C for 10 hours , take out the calcined product, grind it, put it into a boron nitride crucible after passing through a 200-mesh sieve, put it into a nitrogen atmosphere and roast it at 1550°C for 12 hours. The resulting product was ground and sieved, washed with 10% nitric acid, then washed with deionized water and dried to obtain Ca 0.9 Sr 0.9 Si 5 N 8 :Eu 0.2 Nitride red phosphor.

Embodiment 3

[0051] Weigh out CaCN 2 2.040g, SrCO 3 3.764g, Eu 2 o 3 1.584g, Si 3 N 4 7.000g, AlN 0.033g and CaF 2 0.028g Add the above raw materials into a beaker and wet mix them with ethanol for 6 hours, put them in an oven to dry for 24 hours, pass through a 120-mesh sieve and mix evenly, put them into a boron nitride crucible, put them into a nitrogen atmosphere and bake them at 1510°C for 10 hours , take out the calcined product, grind it, put it into a boron nitride crucible after passing through a 200-mesh sieve, put it into a nitrogen atmosphere and roast it at 1550°C for 12 hours. The resulting product was ground and sieved, washed with 10% nitric acid, then washed with deionized water and dried to obtain Ca 0.85 Sr 0.85 Si 5 N 8 :Eu 0.3 Nitride red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com