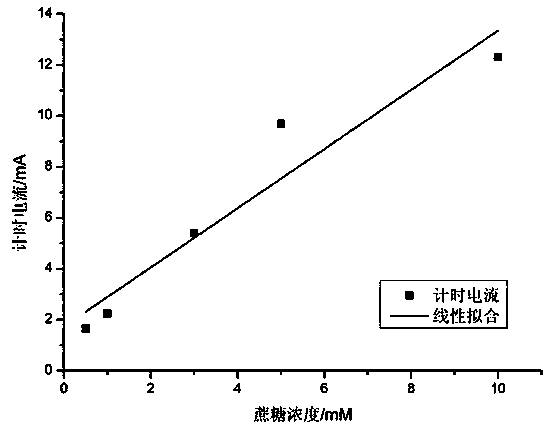

Preparation method of foamy copper for detection of sucrose concentration

A technology of foamed copper and concentration, applied in the direction of material electrochemical variables, etc., can solve the problems of less plating solution usage and more copper powder, and achieve the effect of low cost, high porosity and reusable raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for detecting sucrose concentration with copper foam, said preparation method comprising the following steps:

[0037] a) Soak the polyurethane foam material in the degreasing solution, the temperature is 45°C, and the soaking time is 8 minutes; the formula of the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 35g / L, sodium carbonate 20g / L and 5g / L detergent (purchased from Shenzhen Jichang Lubricating Oil Effective Company);

[0038] b) Coarsening: The polyurethane foam obtained in step a) is subjected to primary roughening at a temperature of 35°C for 15 minutes; then it is taken out and immersed in a secondary roughening solution at a temperature of 60°C for a time 35min; the formula of the primary roughening solution is: 10g / L of chromium trioxide and 8mL / L of sulfuric acid; the formula of the secondary roughening solution is: 15g / L of copper chloride and 10mL / L of sulfosalicyl acid;

[0039] c) Sensitization: immerse th...

Embodiment 2

[0046] A preparation method for detecting sucrose concentration with copper foam, said preparation method comprising the following steps:

[0047] a) Soak the polyurethane foam material in the degreasing solution, the temperature is 50°C, and the soaking time is 15 minutes; the formula of the degreasing solution is: sodium hydroxide 60g / L, sodium phosphate 40g / L, sodium carbonate 22g / L and 5g / L detergent (purchased from Shenzhen Jichang Lubricating Oil Effective Company);

[0048] b) Coarsening: The polyurethane foam material obtained in step a) is subjected to primary roughening at a temperature of 40°C for 9 minutes; then it is taken out and immersed in a secondary roughening solution at a temperature of 70°C for a time of 9 minutes. 30min; the formula of the primary roughening solution is: 12g / L of chromium trioxide and 8mL / L of sulfuric acid; the formula of the secondary roughening solution is: 18g / L of copper chloride and 12mL / L of sulfosalicyl acid;

[0049] c) Sensit...

Embodiment 3

[0055] A preparation method for detecting sucrose concentration with copper foam, said preparation method comprising the following steps:

[0056] a) Soak the polyurethane foam material in the degreasing solution, the temperature is 65°C, and the soaking time is 28 minutes; the formula of the degreasing solution is: sodium hydroxide 75g / L, sodium phosphate 45g / L, sodium carbonate 25g / L and 5g / L detergent (purchased from Shenzhen Jichang Lubricating Oil Effective Company);

[0057] b) Coarsening: The polyurethane foam obtained in step a) is subjected to primary roughening at a temperature of 45°C for 7 minutes; then it is taken out and immersed in a secondary roughening solution at a temperature of 80°C for a time 25min; the formula of the primary roughening solution is: 13g / L of chromium trioxide and 8mL / L of sulfuric acid; the formula of the secondary roughening solution is: 20g / L of copper chloride and 15mL / L of sulfosalicyl acid;

[0058] c) Sensitization: immerse the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com