High-power lithium-ion positive electrode material and preparation method thereof

A cathode material, lithium-ion technology, applied in the field of high-power lithium-ion cathode materials and its preparation, can solve the problems of reducing the stability of the core nickel-cobalt-manganese ternary material, reducing battery performance, and the existence of coating voids, etc., to improve the structure Effects of stability and electrochemical performance, improvement of power performance, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

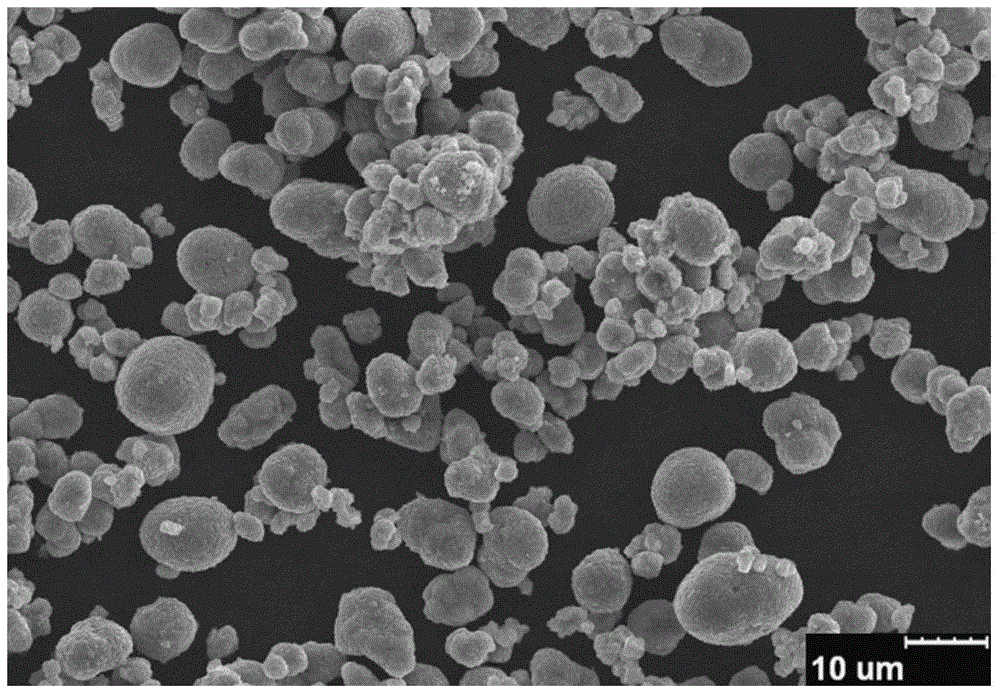

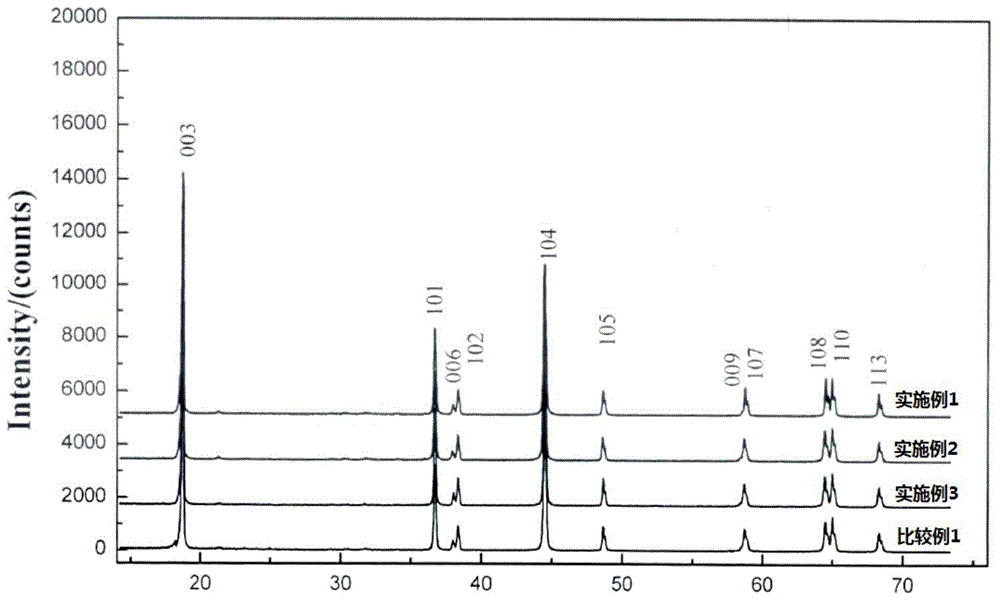

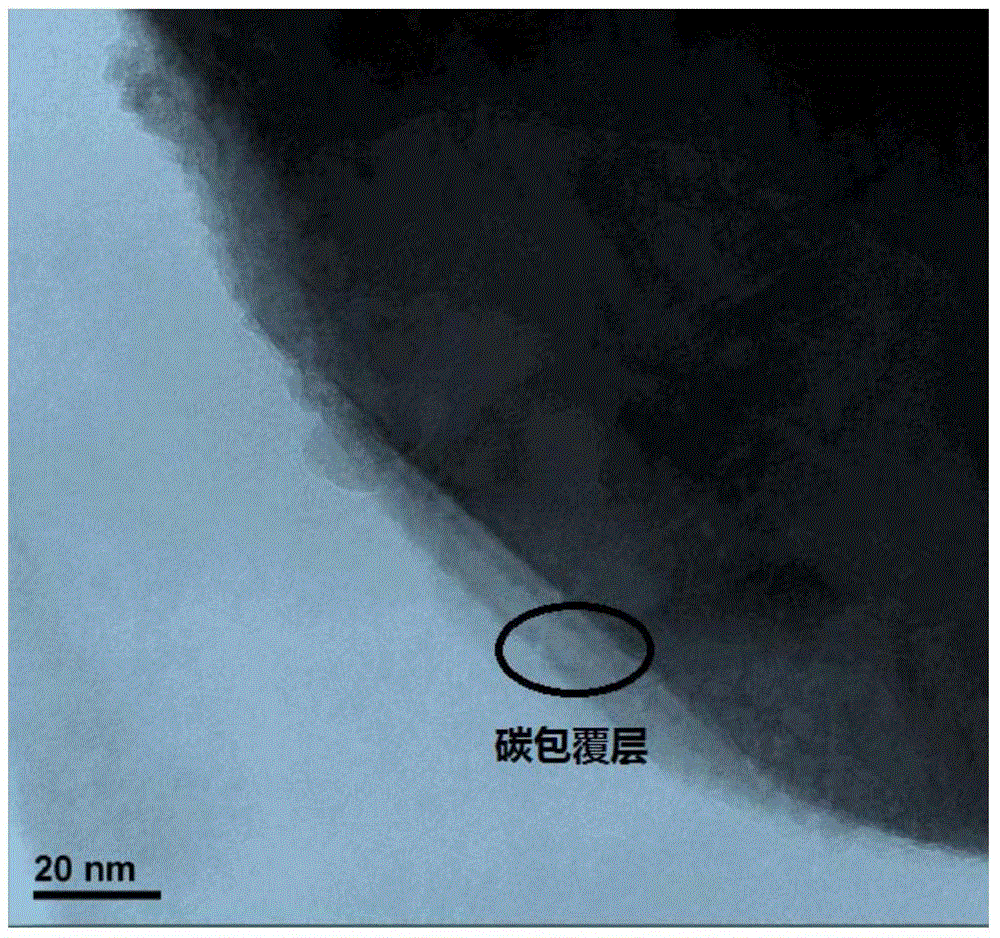

Embodiment 1

[0062] 1. Weigh nickel sulfate and cobalt sulfate crystals at a molar ratio of 9:1, dissolve them in water, mix the nickel sulfate solution and cobalt sulfate solution evenly, and the metal ion concentration is 2.0mol / L. The nickel-cobalt mixed solution is then fed into a continuous reaction kettle with 7mol / L ammonia water and 2mol / L potassium hydroxide solution in parallel. The reaction kettle is filled with bottom liquid with a pH value of 11.5 and a temperature of 50°C. The pH value of the reaction system was controlled at 11.5±0.02 by potassium hydroxide solution, the stirring speed was 500 r / min, and the reaction was carried out for 30 hours. When the pH value of the precipitated product is below 10.5 after washing, the washing is stopped and the slurry is dried. The dried precursor and magnesium oxide were sintered in an oxygen atmosphere at 750°C for 10 hours at a ratio of 1:0.05, and then crushed and classified to obtain the core material Ni 0.86 co 0.1 Mg 0.04 O. ...

Embodiment 2

[0066] (1) With embodiment 1 (1), only dopant is changed into TiO 2 , get Ni 0.86 co 0.1 Ti 0.04 o

[0067] (2) The inner core material that above-mentioned step (1) is made is dispersed in bottom liquid, then the potassium hydroxide solution that mixes uniform nickel, cobalt salt solution and 2mol / L ammoniacal liquor and 0.5mol / L also has lemon Sodium bicarbonate is added into the reaction kettle in parallel with the aluminum solution pre-complexed at 1:1, and the pH value of the reaction system is controlled at 10.5±0.02 by the potassium hydroxide solution. The stirring speed is 600r / min, and the reaction is heated at 60°C for 20h. The solution after the reaction is subjected to solid-liquid separation, the pH value of the precipitated product is below 10 after washing, the washing is stopped and the slurry is dried. The dried precursor and lithium hydroxide were sintered in an oxygen atmosphere at 850° C. for 20 hours at a ratio of 1:1.08, and then pulverized and class...

Embodiment 3

[0070] (1) With embodiment 1 (1), only dopant is changed into ZnO, obtains Ni 0.82 co 0.08 Zn 0.1 o 2 .

[0071] (2) The core material obtained in the above step 1) is dispersed in the bottom liquid, and then the mixed nickel, cobalt salt solution, ammoniacal liquor of 2mol / L and potassium hydroxide solution of 0.5mol / L also have sodium citrate According to the 1:1 pre-complexed aluminum solution co-flow into the reaction kettle, the pH value of the reaction system is controlled at 11±0.02 by the potassium hydroxide solution. The stirring speed was 500r / min, and the reaction was heated at 30°C for 40h. The solution after the reaction is subjected to solid-liquid separation, the pH value of the precipitated product is below 10 after washing, the washing is stopped and the slurry is dried. The dried precursor and lithium hydroxide were sintered in an oxygen atmosphere at 800°C for 30 hours at a ratio of 1:1.05, and then pulverized and classified to obtain a high-nickel cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com