Nitro ferrous phthalocyanine/graphene composite material and preparation method thereof

A technology of nitroferrous phthalocyanine and composite material, applied in the field of nitroferrous phthalocyanine/graphene composite material and preparation thereof, can solve the problems of high manufacturing cost, poor activity and stability of noble metal nanocatalyst, and achieve excellent Catalytic activity, simple and easy synthesis method, and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Disperse 0.5g of graphite and 0.5g of sodium nitrate in 42.32g of concentrated sulfuric acid, slowly add 3g of potassium permanganate under mechanical stirring at 0°C; stir in a water bath at 35°C for 1 hour; add 40g of water, and After stirring at 90°C for 30min, add 100g of water and 4.44g of 30% hydrogen peroxide (H 2 o 2 ) after suction filtration, washing with water and centrifugation until the centrifuged water is neutral, vacuum drying at 45° C. for 12 hours to obtain graphite oxide;

[0032] (2) Disperse 0.1 g of the graphite oxide in 100 g of water to form a graphite oxide aqueous solution; add 0.5 g of sodium polystyrene sulfonate after ultrasonic oscillation of the graphite oxide aqueous solution for 4 h and continue ultrasonication for 1 h, add 1.03 g of hydrazine hydrate React at 100°C for 24 hours, cool to room temperature, centrifuge, and wash with water and ethanol to obtain graphene.

Embodiment 2

[0034] 0.63375g of FeCl 2 4H 2 O and 1.7313g of 4-nitrophthalonitrile were dissolved in n-amyl alcohol, and 1.019g of 1,8-diazabicycloundec-7-ene (DBU) was added, vacuumized 3 times, under N 2 Under air protection, react at 160°C for 6 hours; after the reaction is completed, cool down to room temperature, vacuum filter, first rinse with distilled water, then rinse with acetone, dilute hydrochloric acid with a concentration of 1mol / mL and ethanol, and finally rinse with distilled water until the filtrate The pH value is neutral, and vacuum-dried at 40-50°C for 10 hours to obtain nitroferrous phthalocyanine.

Embodiment 3

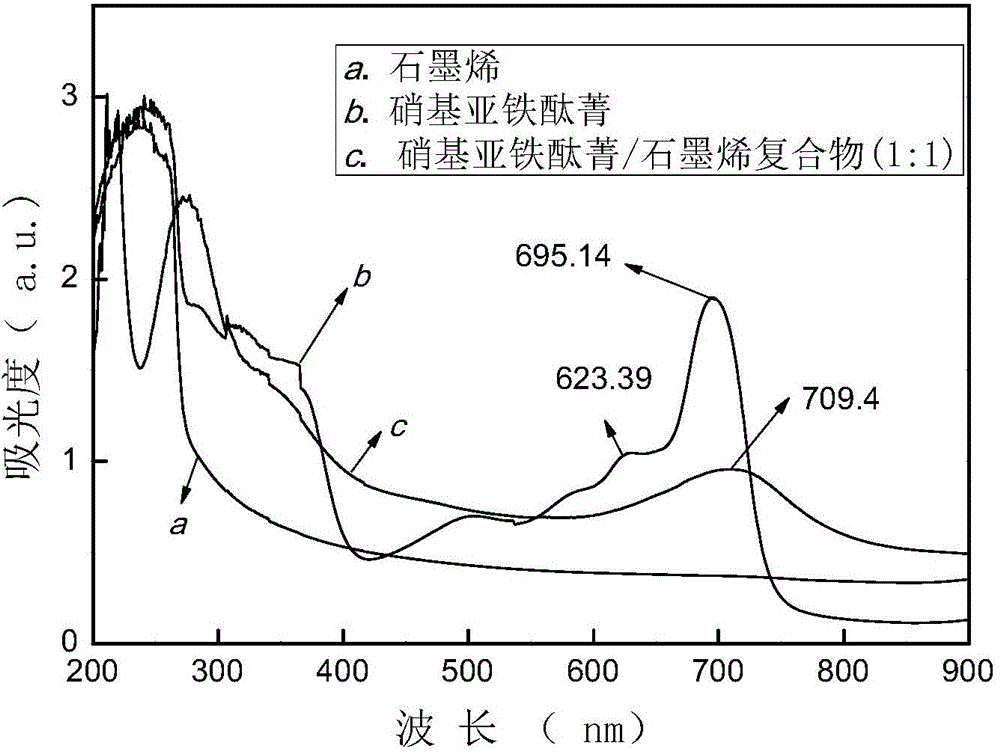

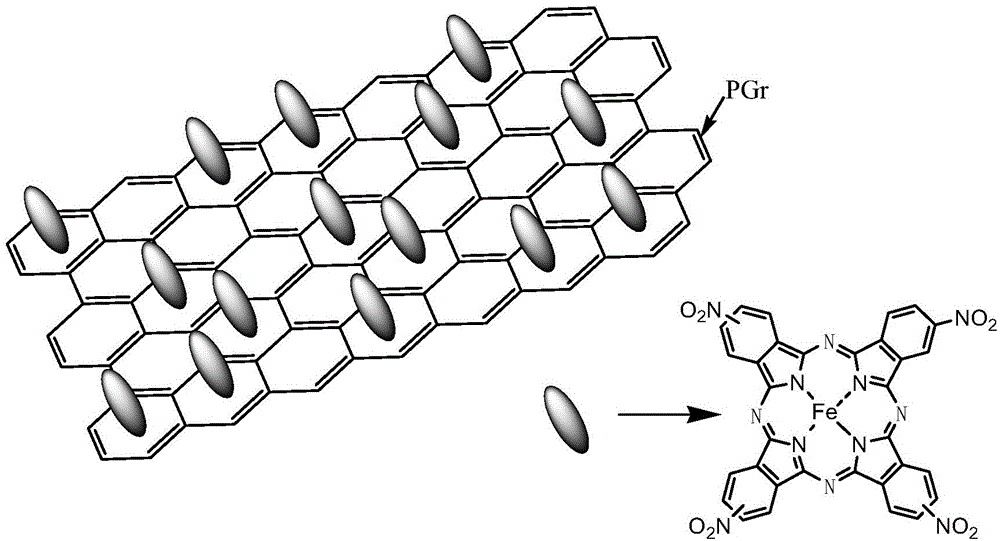

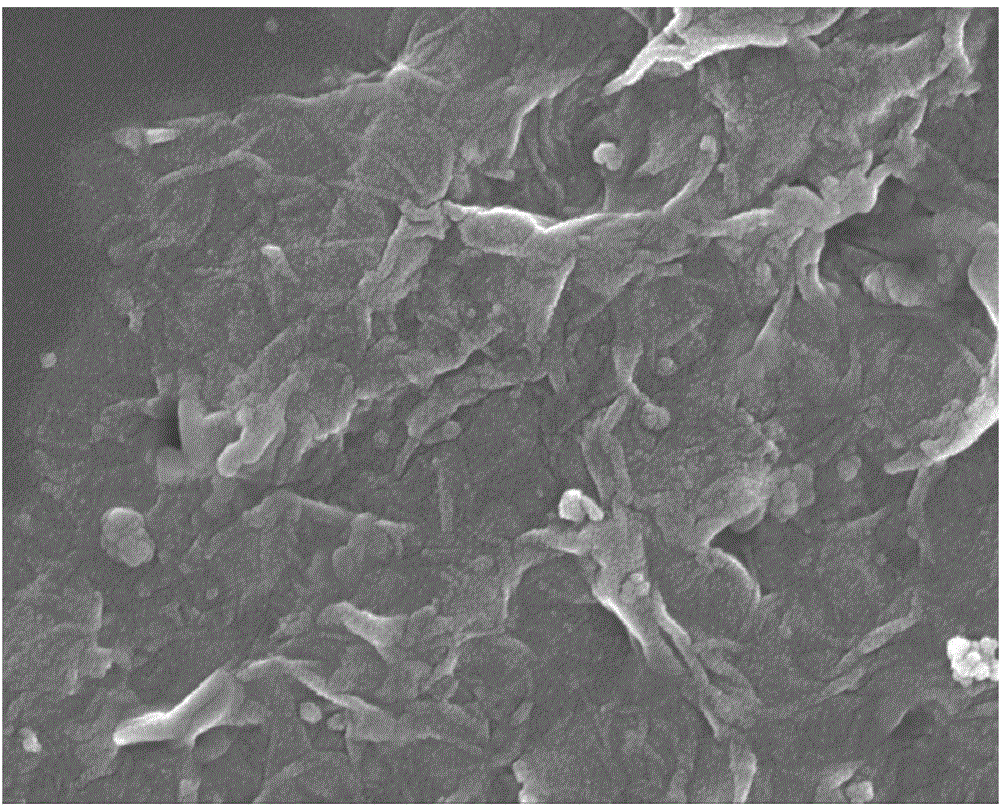

[0036] Disperse 10 mg of graphene in 9.487 g of DMF, add 10 mg of the nitroferrous phthalocyanine, and conduct a hydrothermal reaction at 160 ° C for 12 hours to obtain a nitroferrous phthalocyanine / graphene composite material with a mass ratio of 1:1 [FeTNPc / PGr, 1:1].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com